A kind of multiple emulsion and its preparation method and application

A technology of multiple emulsions and solutions, applied in the fields of polymer materials and applied chemistry, can solve the problems of organic solvent residues and time-consuming, and achieve the effects of high stability, avoidance of removal steps, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

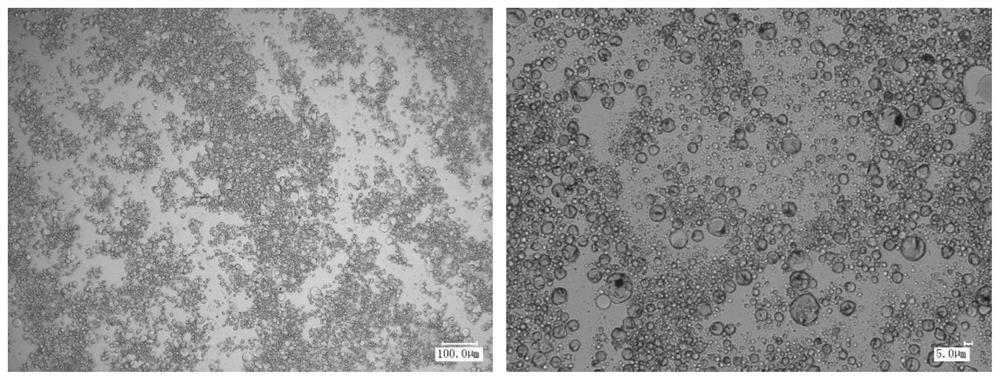

[0031] Embodiment 1: multiple emulsion preparation

[0032] (1) Preparation of random polymer: the molar ratio of hydrophobic monomer lauryl methacrylate to hydrophilic monomer methacrylic acid is 1:4, the initiator is azobisisobutyronitrile (2%), 1, 4-dioxane as solvent, reacted for 24h. Purify with diethyl ether as precipitant.

[0033] (2) Preparation of random polymer solution: Dissolve an appropriate amount of random polymer prepared in step (1) in 0.05M sodium hydroxide solution, wherein the concentration of random polymer is 5 mg / mL, and wait until it is completely dissolved Leave overnight. The resulting polymer solution was adjusted to pH 7.0 with citric acid.

[0034] (3) Mix the water phase of step (2) with caprylic acid / capric triglyceride in a ratio of 1:4 and heat to 60°C to emulsify with a high-speed disperser at a speed of 10000r / min and shear for 5min.

[0035] The stability of the multiple emulsions prepared above was tested by freezing at -18°C for 24 ho...

Embodiment 2

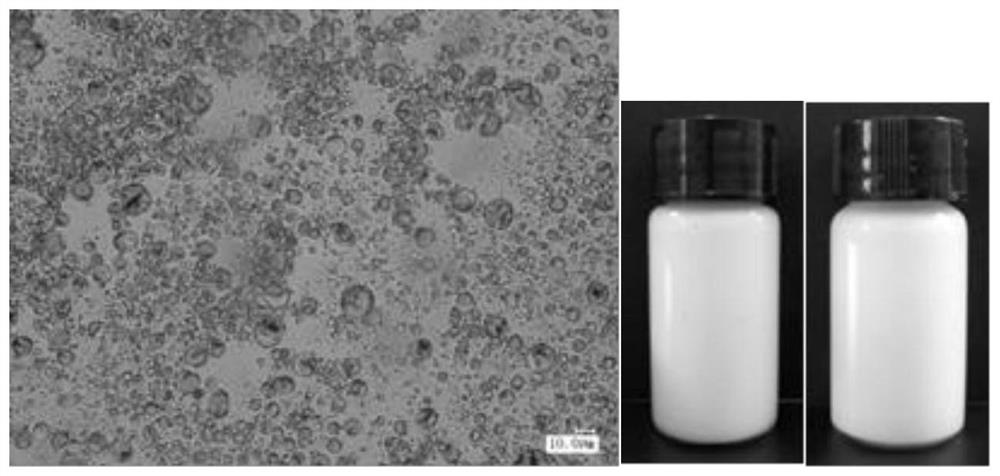

[0037] Embodiment 2: multiple emulsion preparation

[0038] (1) Preparation of random polymer: the molar ratio of hydrophobic monomer octadecyl methacrylate to hydrophilic monomer methacrylic acid is 1:9, the initiator is azobisisobutyronitrile (1.5%), 1, 4-dioxane as solvent, reacted for 24h. Purify with diethyl ether as precipitant.

[0039] (2) Preparation of random polymer solution: Dissolve an appropriate amount of random polymer prepared in step (1) in 0.05M sodium hydroxide solution, wherein the concentration of random polymer is 5 mg / mL, and wait until it is completely dissolved Leave overnight. The resulting polymer solution was adjusted to pH 7.0 with citric acid.

[0040] (3) Mix the water phase of step (2) with jojoba oil in a ratio of 1:3, heat to 60°C and emulsify with a high-speed disperser at a speed of 10,000r / min and shear for 5min.

[0041] The stability of the multiple emulsions prepared above was tested by freezing at -18°C for 24 hours, returning to r...

Embodiment 3

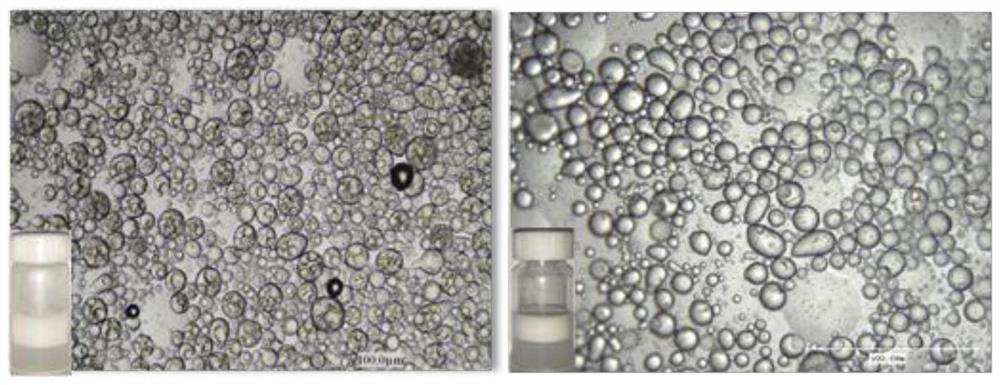

[0042] Embodiment 3: multiple emulsion preparation

[0043] (1) Preparation of random polymer: the molar ratio of hydrophobic monomer lauryl methacrylate to hydrophilic monomer methacrylic acid is 1:19, the initiator is azobisisobutyronitrile (2%), 1, 4-dioxane as solvent (2%), reacted for 24h. Purify with diethyl ether as precipitant.

[0044] (2) Preparation of random polymer solution: Dissolve an appropriate amount of random polymer prepared in step (1) in 0.05M sodium hydroxide solution, wherein the concentration of random polymer is 5 mg / mL, and wait until it is completely dissolved Leave overnight. The resulting polymer solution was adjusted to pH 7.0 with citric acid.

[0045] (3) Mix the water phase of step (2) with caprylic acid / capric triglyceride in a ratio of 1:4 and heat to 60°C to emulsify with a high-speed disperser at a speed of 10000r / min and shear for 5min.

[0046] The stability of the multiple emulsions prepared above was tested by freezing at -18°C for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com