Hydrocarbon material selective hydrogenation catalyst and preparation method thereof

A technology for selective hydrogenation and catalysts, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems that do not involve a small amount of oxides, and achieve improvement Effects of dispersion, enhanced synergy, and increased yield of monoolefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

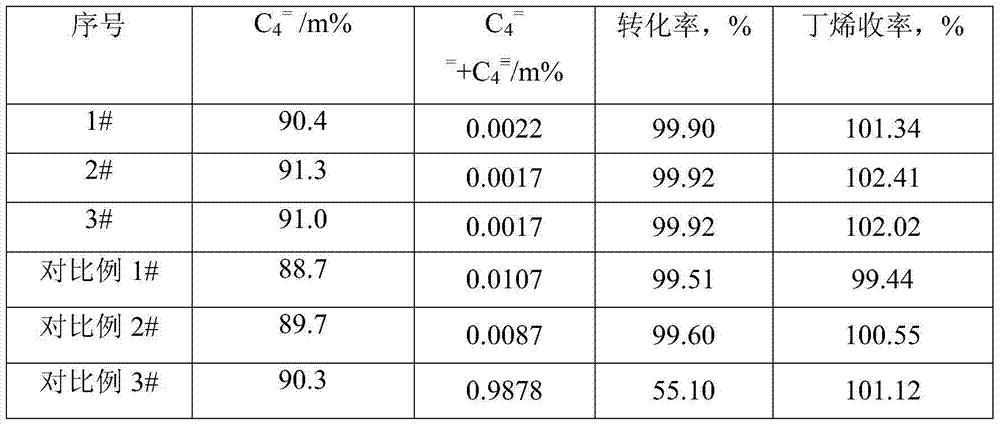

Examples

Embodiment 1

[0034] The catalyst carrier was prepared by adding 5% potassium carbonate and additives to aluminum hydroxide powder. Accurately weigh a certain weight carrier; accurately weigh PdCl 2 , tin protochloride, add water to dissolve respectively and adopt ultrasonic treatment homogeneous treatment, be mixed with a certain concentration solution; Get an appropriate amount of solution, make its consumption make the main and auxiliary active component content of the catalyst finally prepared meet the requirements of the prepared catalyst, The preparation of carrier and catalyst is as follows:

[0035] 1. Preparation of Vector

[0036] Add 5% potassium carbonate to aluminum hydroxide powder and mix it with additives to form a strip with a diameter of 2 mm, and roast it at the following temperature to obtain a carrier.

[0037] a. Dry at room temperature for 24 hours

[0038] b. Dry at 120°C for 4 hours

[0039] c. Raise the temperature from 120°C to 800°C and keep the temperature c...

Embodiment 2

[0046] The preparation process is the same as in Example 1. Load K, Pd, and Pb on the carrier in sequence.

[0047] 1. Preparation of Vector

[0048] Alumina powder is mixed with additives to form a spherical shape with a diameter of 2 mm, and fired at the temperature according to Example 1 to obtain the carrier 1.

[0049] Potassium nitrate is dissolved in water to make a certain concentration of potassium solution, which is fully dissolved in a transducer with an ultrasonic power of 60w. Take 100ml carrier and soak it in 60ml liquid. When the remaining liquid is completely transparent, take it out and drain it. Dry at constant temperature for 4 hours, and then bake at 600° C. for 4 hours to obtain carrier 2 .

[0050] 2. Catalyst Preparation

[0051] According to the catalyst Pd content requirement of 0.28%, prepare PdCl2 solution, put it in a transducer with an ultrasonic power of 300w to fully dissolve it, and immerse the carrier 2 prepared by the above method in the Pd...

Embodiment 3

[0053] The carrier preparation method is the same as in Example 2. Alumina powder and additives are mixed to form a strip with a diameter of 2 mm, and fired at the temperature of Example 1 to obtain a carrier 1; K, Pd, and Au are loaded on the carrier in sequence.

[0054] According to the catalyst Pd content requirement of 0.28%, prepare PdCl 2 Solution; the Au content is 0.03% according to the requirements of the catalyst to prepare a chloroauric acid solution, which is fully dissolved in a transducer with an ultrasonic power of 800w. Immerse the carrier 2 prepared by the above method in the Pd-containing solution at a constant temperature of 25°C, treat it with ultrasonic waves for 5 minutes, and stir evenly to make the main active components evenly distributed on the surface of the carrier, and filter the remaining liquid after 40 minutes. Dry at 120°C for 2 hours; then place it in a gold-containing solution for immersion, ultrasonic treatment for 6 minutes, filter off th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com