Method for preparing boric acid ester based on n-butyllithium

A technology of n-butyllithium and borate, which is applied in the field of preparation of borate based on n-butyllithium, can solve the problems of high cost, difficult catalyst, high safety risk, etc., achieve short reaction time, high reaction yield, Post-processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

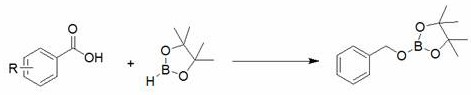

[0023] Embodiment one: N-butyllithium catalyzes the hydroboration reaction of benzoic acid and pinacol borane

[0024] Under an inert gas atmosphere, add benzoic acid (61.1 mg, 0.5 mmol) to the dehydrated and deoxygenated reaction flask, add pinacol borane (218 μL, 1.5 mmol) with a pipette gun, and finally add 25 μL n-butyl Lithium tetrahydrofuran solution (0.1M) (0.5 mol% dosage, the same below), reacted at room temperature for 45 minutes, exposed the reaction solution to air, and removed the solvent to obtain the product borate, which was obtained by s-trimethoxybenzene (84.15 mg , 0.5 mmol) as internal standard, with CDCl 3 Dissolved, stirred for 10 minutes, sampled, and NMR. Calculated 1 The yield of H is 97%; 3 (THF) 2 , no product is obtained. NMR data of the product: 1 H NMR (400 MHz, CDCl 3 ) : δ 7.22– 7.32 (m,5H, ArH), 4.92 (s, 2H, CH 2 ), 1.26 (s, 36H, CH 3 ).

Embodiment 2

[0029] Embodiment two: n-butyllithium catalyzed hydroboration reaction of benzoic acid and pinacol borane

[0030] Under an inert gas atmosphere, add benzoic acid (60.7 mg, 0.5 mmol) to the dehydrated and deoxygenated reaction flask, add pinacol borane (217 μL, 1.5 mmol) with a pipette, and finally add n-butyl The tetrahydrofuran solution of lithium (0.5 mol%) was reacted at room temperature for 20 minutes, the reaction solution was exposed to air, and the solvent was removed to obtain the product borate, with s-trimethoxybenzene (84.10 mg, 0.5 mmol) as the internal standard, with CDCl 3 Dissolved, stirred for 10 minutes, sampled, and NMR. Calculated 1 H yield was 62%. NMR data of the product: 1 H NMR (400 MHz, CDCl 3 ) : δ 7.21– 7.31 (m,5H, ArH), 4.92 (s, 2H, CH 2 ), 1.25 (s, 36H, CH 3 ).

Embodiment 3

[0031] Embodiment three: N-butyllithium catalyzes the hydroboration reaction of benzoic acid and pinacol borane

[0032] Under an inert gas atmosphere, add benzoic acid (59.9 mg, 0.5 mmol) to the reaction flask after dehydration and deoxygenation treatment, add pinacol borane (289 μL, 2 mmol) with a pipette gun, and finally add n-butyl The tetrahydrofuran solution of lithium (0.5 mol% dosage) was reacted at room temperature for 45 minutes, the reaction solution was exposed to air, and the solvent was removed to obtain the product borate, with s-trimethoxybenzene (82.50 mg, 0.5 mmol) as the internal standard, with CDCl 3 Dissolved, stirred for 10 minutes, sampled, and NMR. Calculated 1 H yield was 99%. NMR data of the product: 1 H NMR (400 MHz, CDCl 3 ) : δ 7.21– 7.31 (m,5H, ArH), 4.92 (s, 2H, CH 2 ), 1.25 (s, 36H, CH 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com