Automatic optical detection device and method applicable to artificial intelligence detection PCB

A technology of automatic optical detection and automatic detection device, which is used in measurement devices, material analysis by optical means, scientific instruments, etc., can solve problems such as low efficiency of detection systems, and achieve the effect of improving work efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

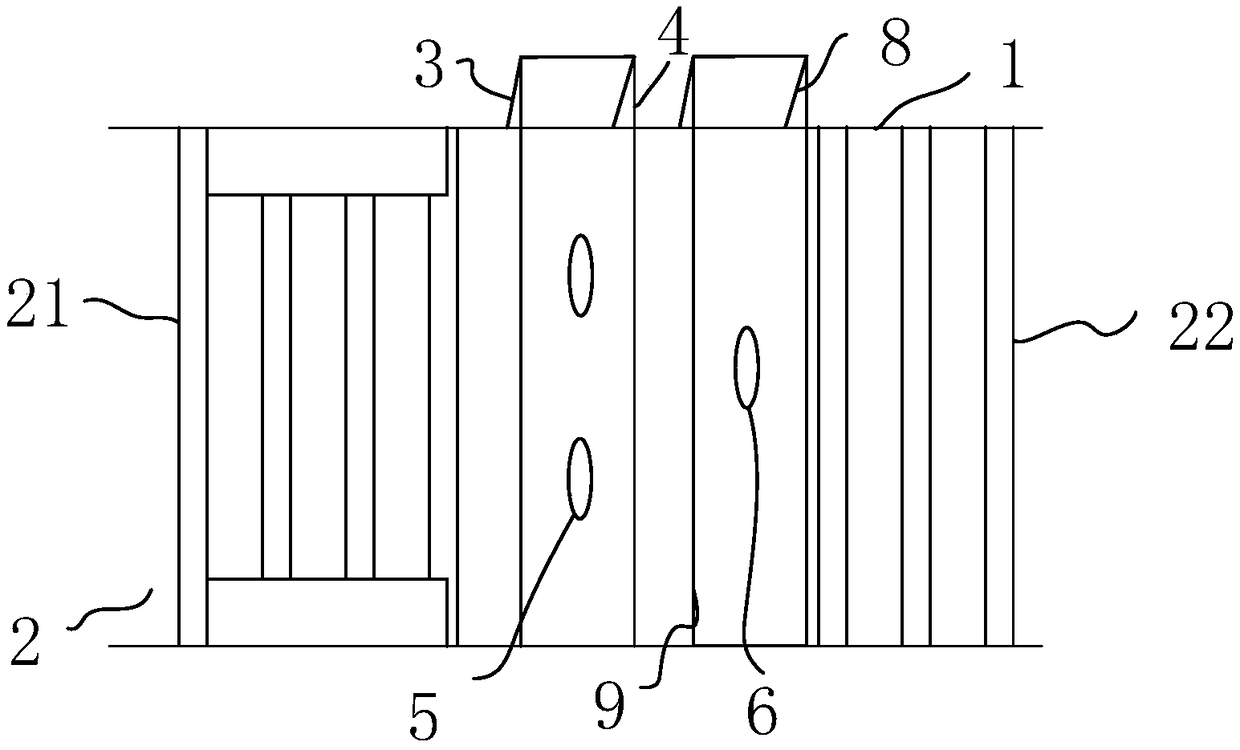

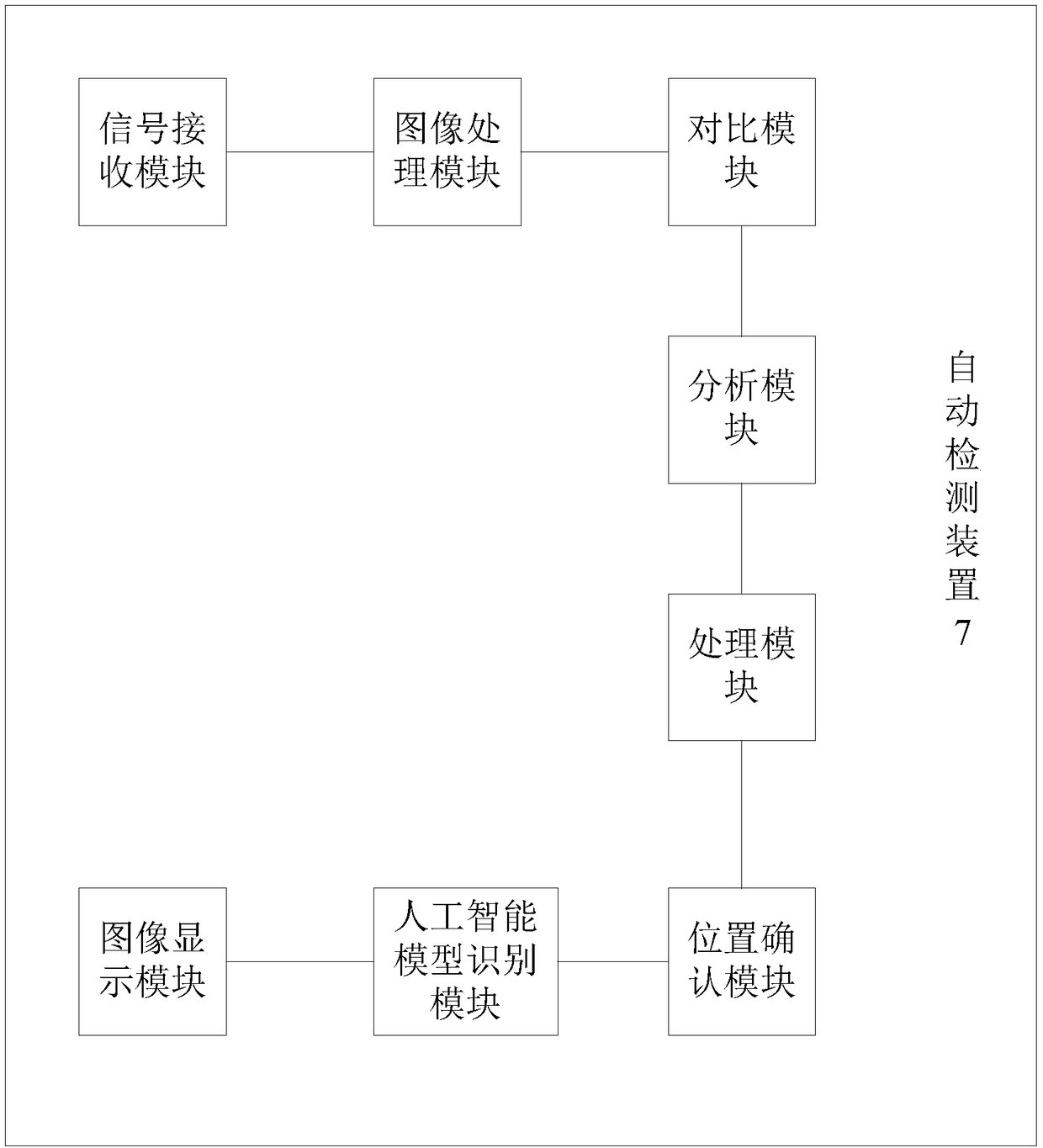

[0034] The invention can make the object under test realize the gray-scale image and color image under the action of the scanning camera and the photographing camera to detect whether there is a defect in the object under test, and the defect of the object under test can be clearly known through the gray-scale image, and its Carry out position confirmation, and the position of the defect of the object under test can be enlarged through the color image to confirm the defect, so as to repair it. Such as figure 1 As shown, it includes a frame 1, the frame 1 is provided with a transfer platform 2, and the transfer platform 2 is provided with a feed section 21 and a discharge section 22, both of which are located on the same transfer platform 2. The frame 1 is provided with a first bracket 3 and a second mobile bracket 8, and the first bracket and the second mobile bracket 8 are all horizontally mounted on the transmission platform 2, and are vertically arranged with the transmissi...

Embodiment 1

[0037] On the contact of above-mentioned embodiment, aim at the deficiency of photographing camera 6, increase a photographing camera to make up for the possibility that the precision is not high, this structure is also relatively simple, by increasing one on the rear end of original photographing camera identical with the original As for the camera, both of them are arranged on the same axis, and the requirement of precision is realized through the second camera.

[0038]In the present invention, the scanning of the scanning camera 5 and the photographing of the photographing camera 6 are set synchronously, so as to ensure that the scanning camera and the photographing camera can simultaneously collect the same object to be measured and ensure its accuracy. The main purpose of one or several camera cameras is to make the working time of the scanning camera and the camera camera tend to be consistent, and at the same time automatically mark according to the recognition results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com