A Method for Precise Extraction of Cycloidal Gear Profile Error and Rapid Analysis of Key Shape and Position Accuracy

An accurate extraction and rapid analysis technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of insufficient utilization of equipment, accuracy less than 1nm, and high price of white light interferometer, achieving good application prospects and convenient processing , to meet the effect of rapid and precise detection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

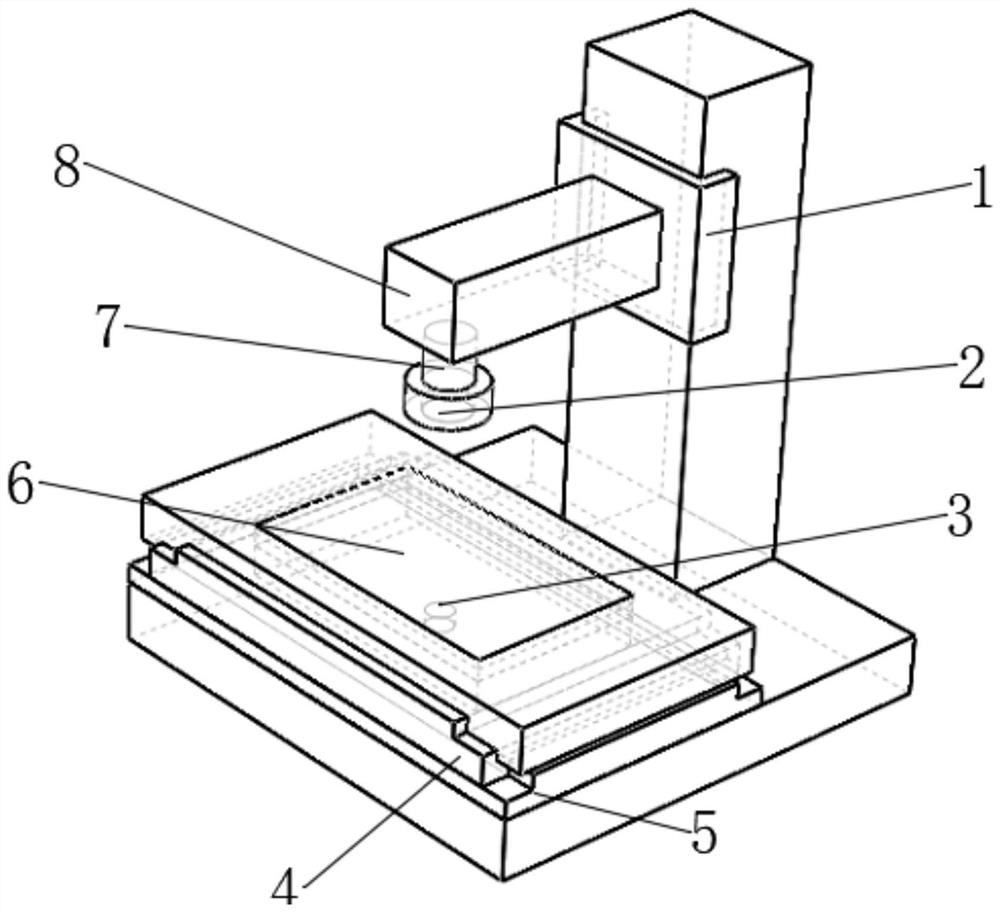

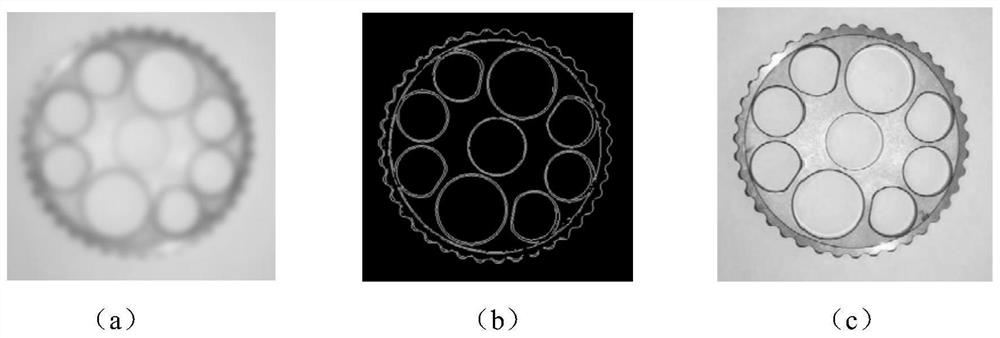

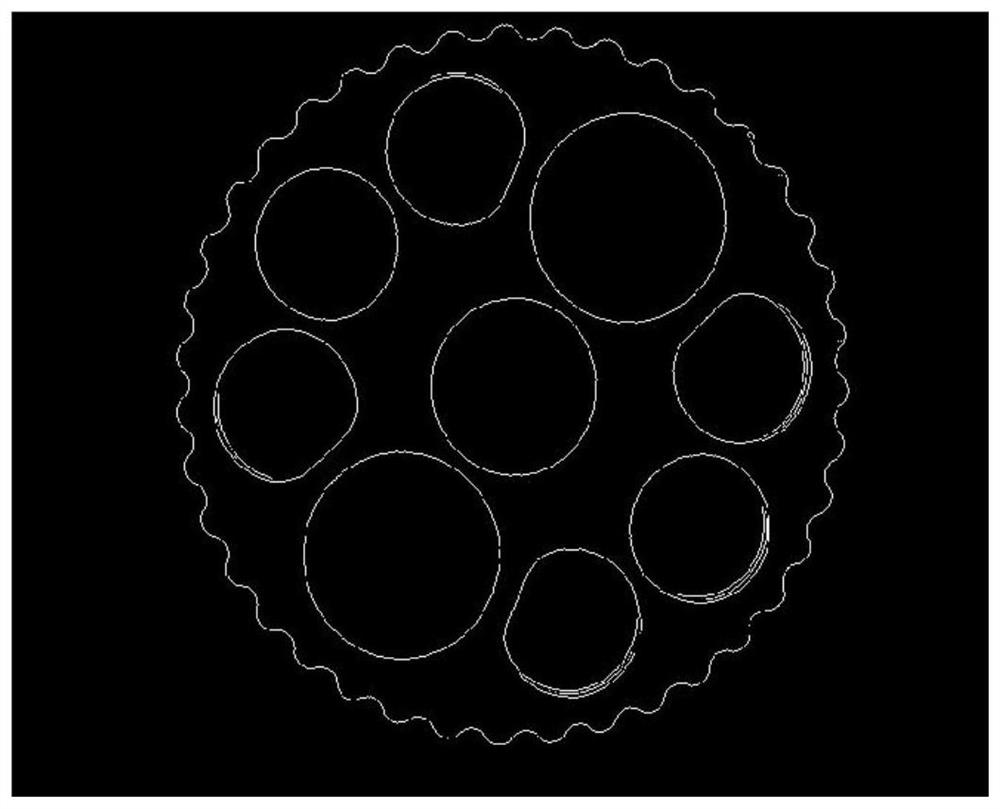

[0042] see Figure 11 , on the basis of an optical rapid detection three-axis measurement platform, the present invention adopts the variable magnification automatic path planning method to realize the position accuracy detection of the cycloidal gear tooth profile and the installation hole, and the detection process completes the gear image acquisition under the panoramic measurement field of view in turn, and the installation Extraction of hole profile and tooth profile, automatic path planning, accurate measurement and acquisition of gear images in the field of view (according to path planning), and obtain various contour coordinate points through image data processing technology, and analyze and calculate according to the extracted installation hole contour position coordinates Install the position error of the hole and complete the accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com