Hoisting mechanism of nuclear reactor pressure vessel inspection mechanism and implementation method

A pressure vessel and inspection device technology, which is applied in the fields of nuclear reactor monitoring, reactors, and reactor fuel elements, etc., can solve problems such as the inability to realize fast automatic hooking and decoupling of inspection equipment, the long distance of moving table bridges of inspection equipment, and the influence on the use of circular cranes, etc. Achieve fast and accurate remote positioning, improve hoisting efficiency, and reduce working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

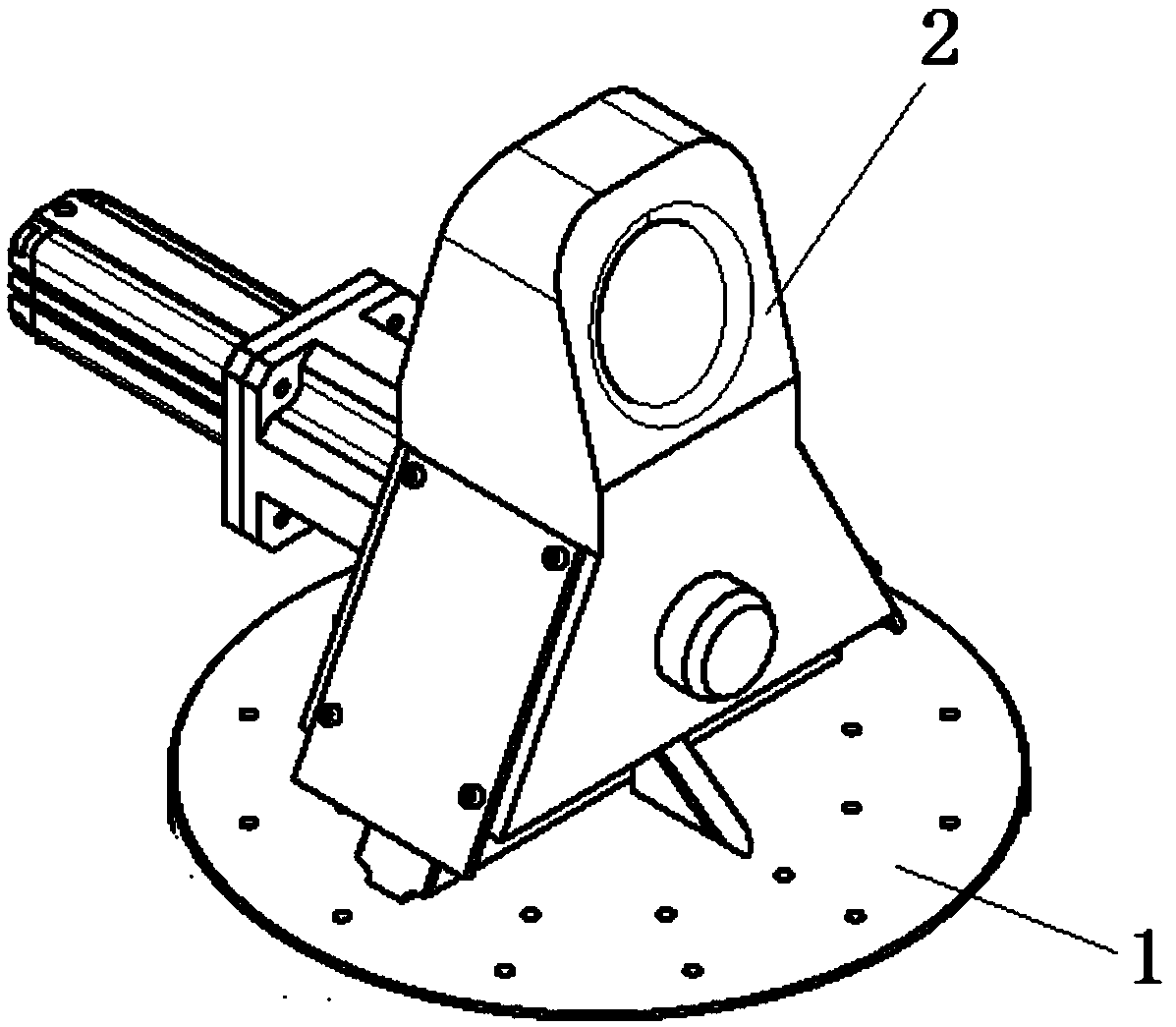

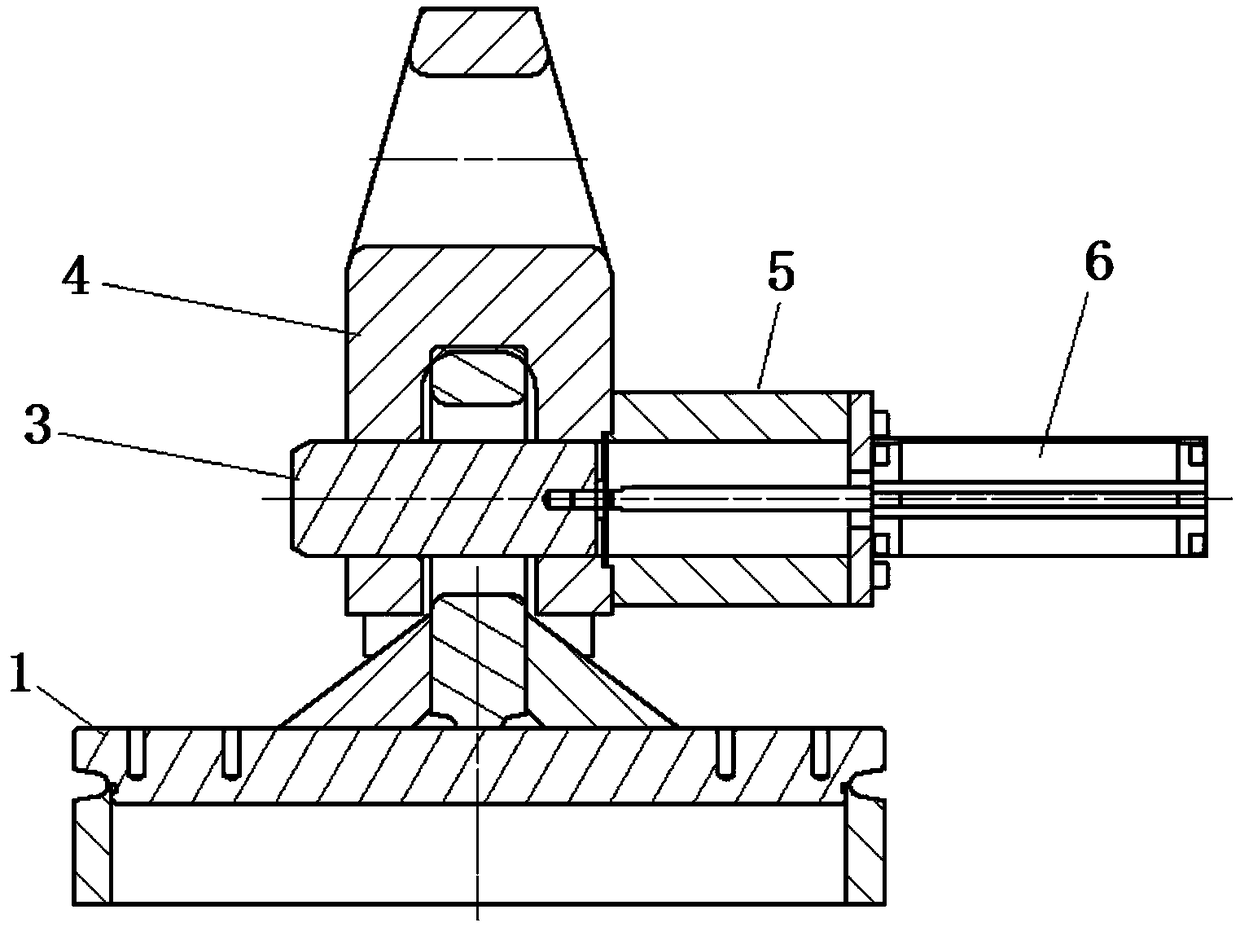

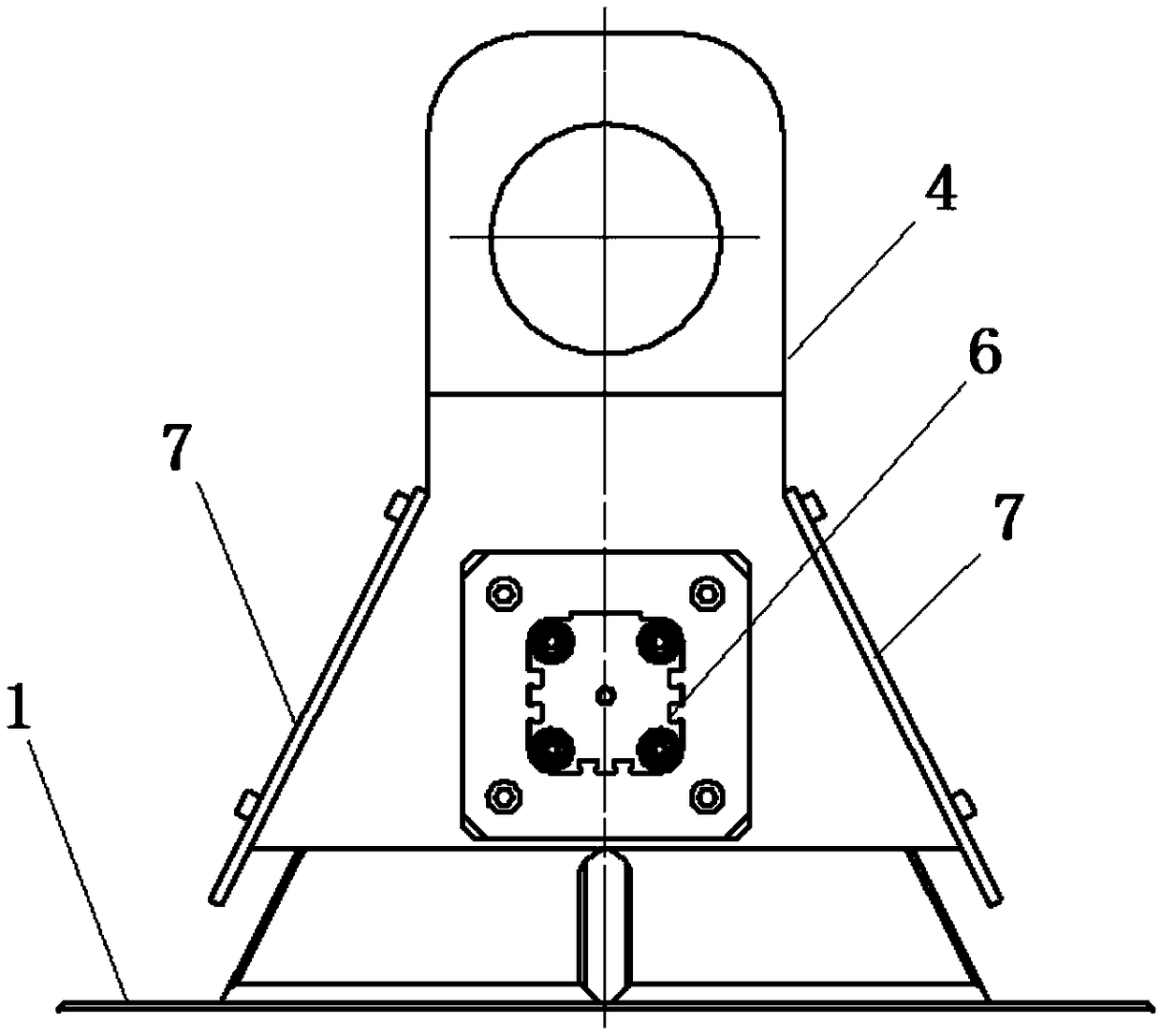

[0024] like Figure 1 to Figure 4 As shown, a lifting mechanism of a nuclear reactor pressure vessel inspection device includes a locking rod 3 , a lifting mechanism body 4 , a cylinder seat 5 , a cylinder 6 and a side guide plate 7 . The shape and structure of the main body 4 of the hoisting mechanism are determined according to the structural features of the hoisting part 1 of the pressure vessel inspection device. A hoisting hole connected to the hook is processed on the upper part of the main body 4 of the hoisting mechanism, and a hoisting part of the pressure vessel inspection device is processed on the lower part of the main body 4 of the hoisting mechanism. 1. Matching guide grooves are processed with a locking pin connecting hole at the guide grooves. Cylinder 6 is connected with hoisting mechanism main body 4 by cylinder block 5, and locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com