High flame-retardant cable

A high flame retardant, cable technology, used in cables, insulated cables, conductors, etc., can solve the problems of large heat release, flammability, increase production cost and production difficulty, and achieve low production difficulty and good fire resistance. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

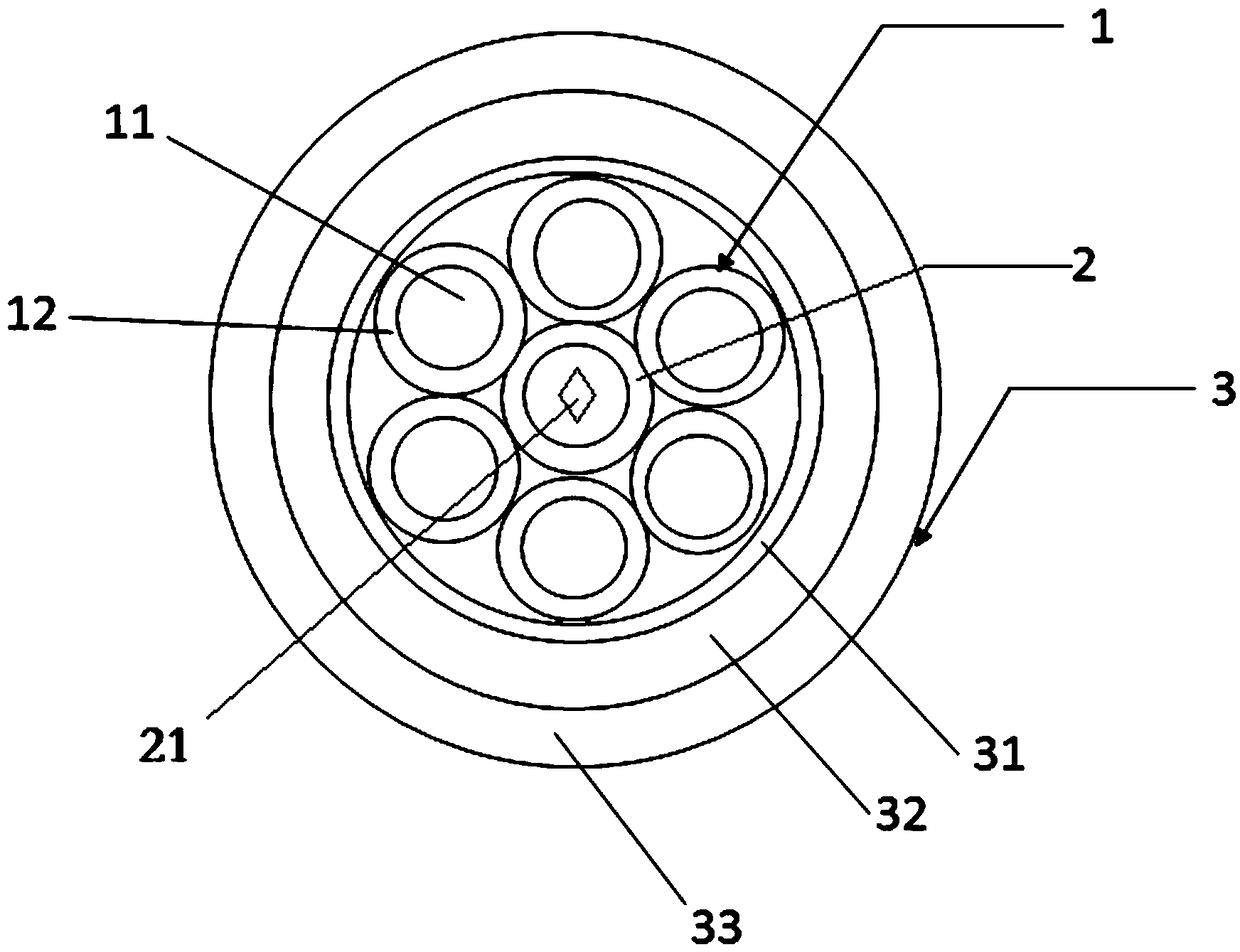

[0020] A high flame-retardant cable, comprising a conductor layer (1), a flame-retardant tube (2) and a sheath layer (3); the conductor layer (1) includes at least one conductor unit, and the conductor unit includes a conductor and The insulation layer wrapped on the conductor, each of the conductor units is enclosed to form a bundle structure and surrounded by a flame-retardant tube, and the flame-retardant tube is filled with a flame-retardant material (21); the sheath layer includes A tape layer, a silicon rubber layer and an outer sheath layer are attached in sequence, the thickness of the silicon rubber layer is 2 mm; the tape layer is wrapped around the outer wall of the beam structure.

[0021] Further, in a highly flame-resistant cable, the number of said conductor units is 6.

[0022] Further, in a highly flame-resistant cable, the number of the flame-retardant tube (2) is one.

[0023] Further, in a highly flame-resistant cable, the conductor (11) is a copper core c...

Embodiment 2

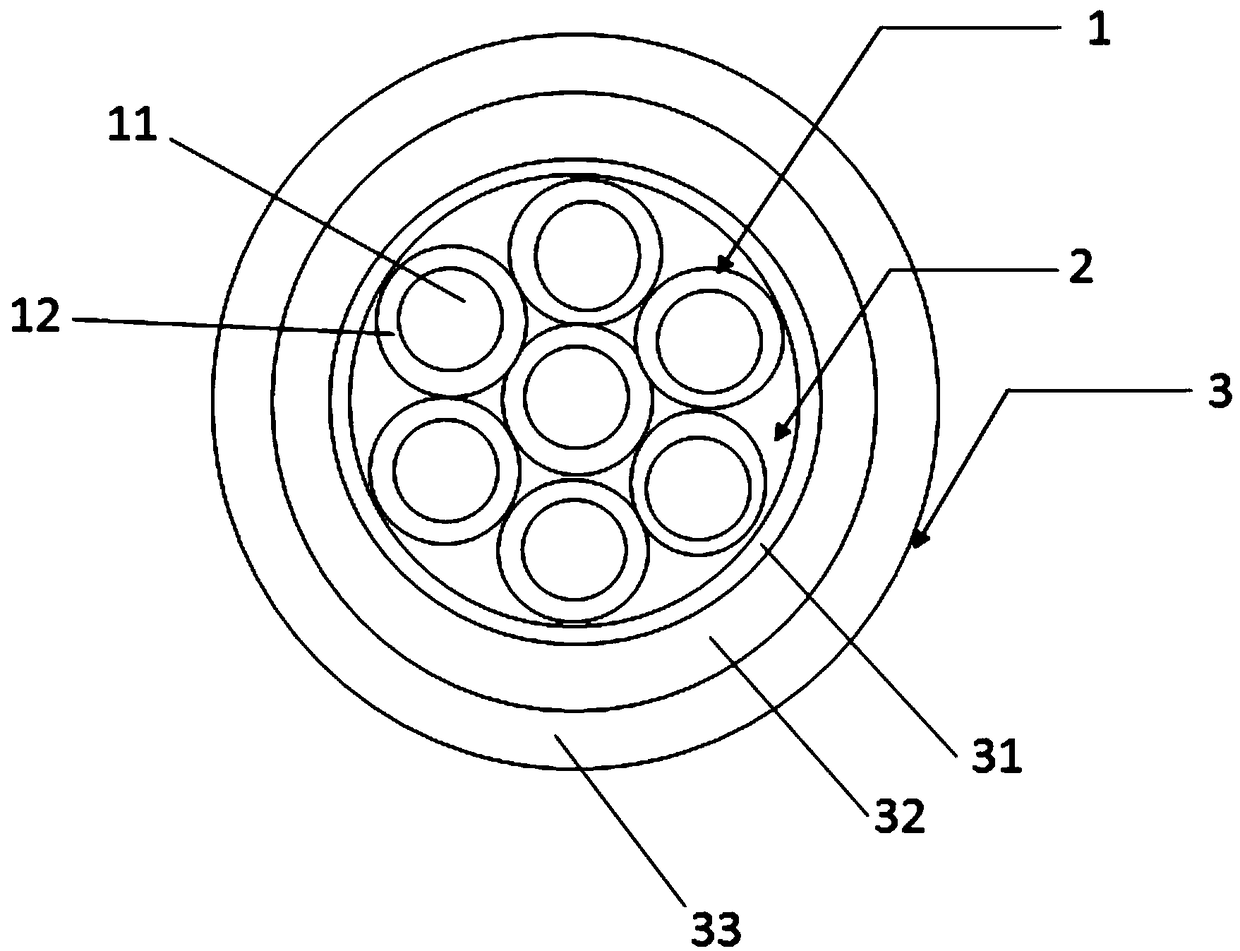

[0032] This embodiment will give different ways of setting flame retardant materials. In the high flame retardant cables of this embodiment, as in figure 2 As shown in , 1 is the conductor layer. The number of conductor units is 7, and its cross section is circular. The other 6 conductor units are evenly distributed on the periphery of one conductor unit. The outer surface of one conductor unit is tangent to the outer surfaces of the other six conductor units; the outer surfaces of the other six conductor units are connected in tangent in pairs, and the center forms a hexagon. Each conductor unit is surrounded to form a bundle structure. The conductor unit also includes a conductor 11 and an insulating layer 12 . The insulating layer 12 covers the periphery of the conductor 11 . The insulating layer 12 is made of cross-linked polyethylene, and the conductor 11 is made of copper. Layers of cross-linked polyethylene material resist moisture, seal and electrically insulate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap