LED device and manufacturing method thereof

A technology of LED devices and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of uncontrollable enhancement of the surface of light-transmitting colloids, poor surface molding quality, and large light output angles, etc., to achieve good processing convenience, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

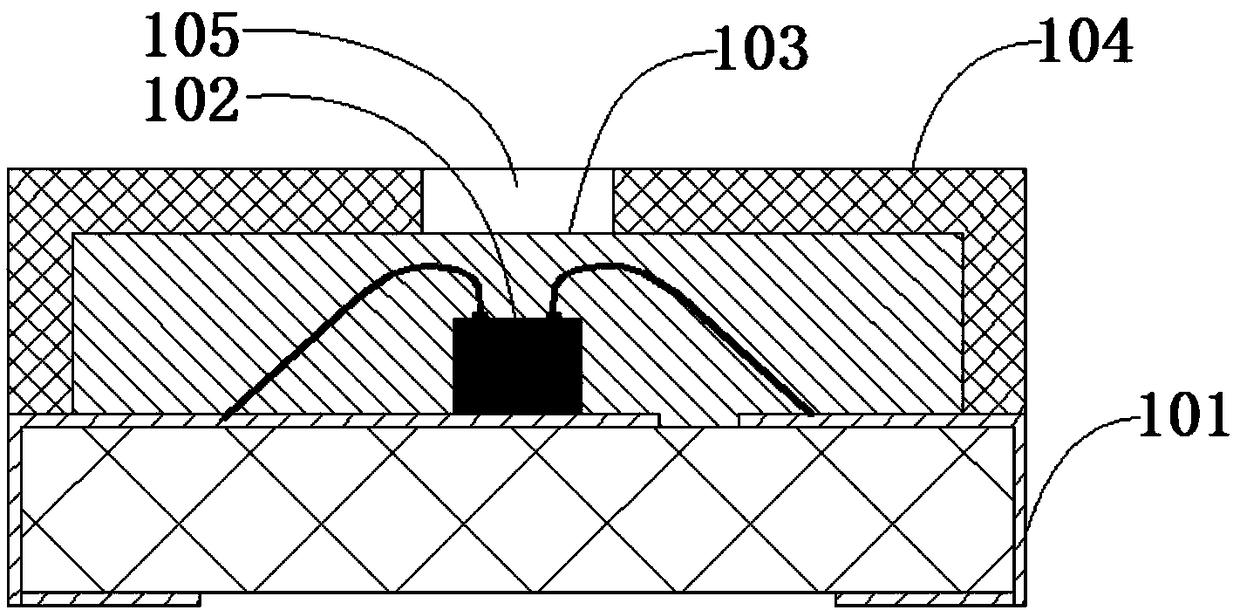

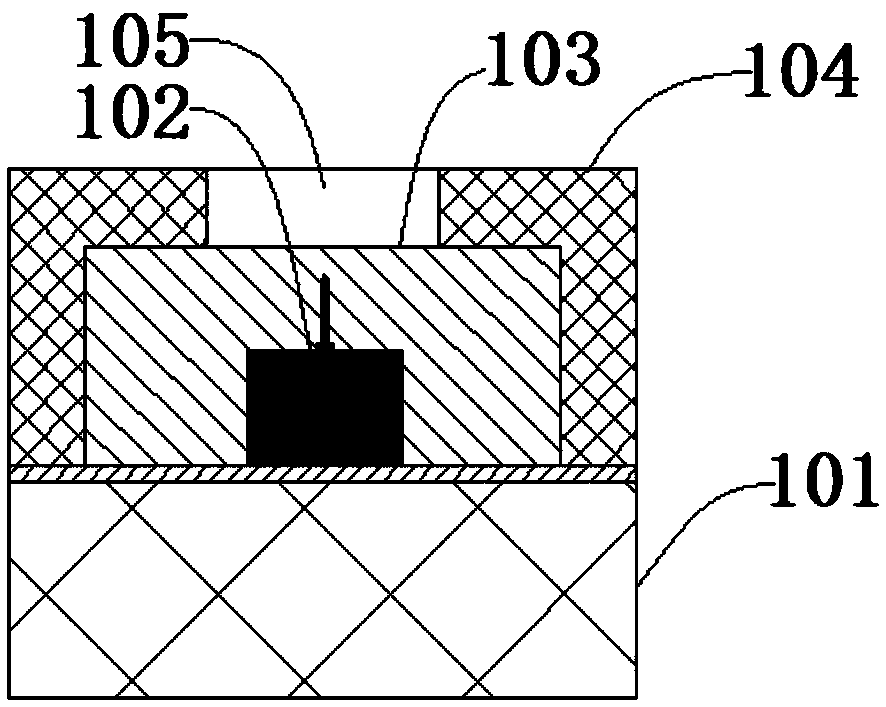

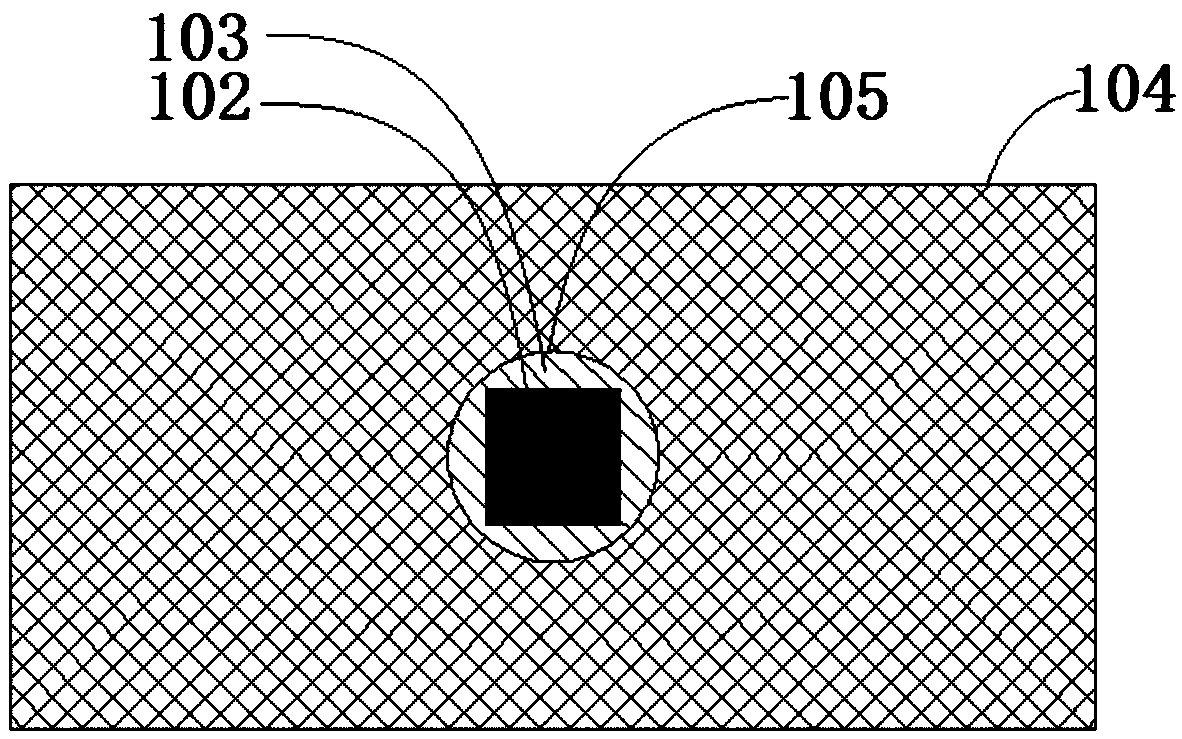

[0069] figure 1 Shows a front cross-sectional view of an LED device according to an embodiment of the present invention, figure 2 shows a side cross-sectional view of an LED device according to an embodiment of the present invention, image 3 A top view of an LED device according to an embodiment of the present invention is shown. The LED device of the embodiment of the present invention includes a substrate unit 101 , a light-transmitting unit 103 , a light-shielding unit 104 and a light-emitting unit 102 .

[0070] Specifically, the substrate unit 101 is a rectangular structure, the light-emitting unit 102 is fixed in the middle of the substrate unit 101, the light-transmitting unit 103 covers the light-emitting unit 102, and is connected and fixed with the substrate unit 101; the light-shielding unit 104 covers the transparent The periphery of the light unit 103, the four sides are respectively perpendicular to the substrate unit 101, and the top surface is parallel to t...

Embodiment 2

[0073] Figure 5 A schematic diagram of the principle of the optical path of the LED device according to the embodiment of the present invention is shown. In a specific implementation, in order to further enhance the concentration of light and reduce the light exit angle, the contact surface between the light-transmitting unit and the light-transmitting part can be designed as a concave surface 501 that is sunken toward the direction of the light-emitting unit. The concave surface 501 has a certain converging effect on the light emitted from the light emitting unit. With the accompanying drawing in embodiment one Figure 4 For reference, the light originally blocked by the light-shielding inner wall in Embodiment 1 can be transmitted through the light-transmitting part after being converged by the concave surface 501. Compared with the top surface of the light-transmitting unit being a plane, under the same circumstances, the light-transmitting part The intensity of the ligh...

Embodiment 3

[0075] In Embodiments 1 and 2, the light-transmitting part is arranged on the top surface of the light-shielding unit, that is, the light-transmitting part is arranged on the top of the light-transmitting unit facing the light-emitting surface of the light-emitting unit, so that the light emitted by the light-emitting unit can only be emitted from the top surface. It penetrates through the light-transmitting part, so as to realize the purpose of controlling the light direction.

[0076] Specifically, it is also possible to arrange the light-transmitting part on the side of the light-shielding unit.

[0077] Figure 6 Shows a front cross-sectional view of an LED device according to an embodiment of the present invention, Figure 7 A side cross-sectional view of an LED device according to an embodiment of the present invention is shown. Specifically, in the embodiment of the present invention, the arrangement form of the substrate unit 101, the light-emitting unit 102, the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com