Inclined shaft plow blade arm assembly

A technology of arm components and coulters, applied in the direction of bearing components, bearings, shafts and bearings, etc., can solve the problems of different farming depths, low efficiency, and no way to adjust the angle of the cutterhead, etc., to achieve strong flexibility, realize working height, Achieve the effect of tillage depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

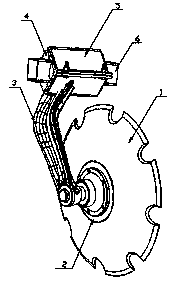

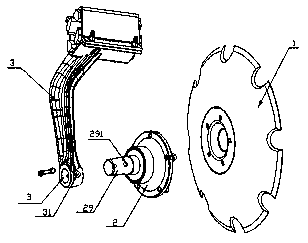

[0024] The invention discloses an inclined-axis coulter arm assembly, which includes: a notched rake blade 1 , a coulter arm 3 , a hub unit 2 , a V-shaped plate 5 and a rubber suspension 4 .

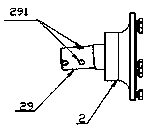

[0025] The hub unit 2 adopts the second-generation integrated maintenance-free hub bearing, which has excellent sealing performance and does not require maintenance in the later stage. Specifically, the hub unit 2 includes an integral flanged outer ring 21 , an inner ring 22 , a cage 23 , rolling elements 24 , an LLU sealing ring 25 , an end face seal 27 and an inclined shaft 29 . Wherein, one end of the integral flange outer ring 21 has a flange 211 connected with the notch rake 1, and the flange 211 is provided with a threaded hole 212, and the flange 211 can be realized through the threaded hole 212. The quick connection with the notched harrow 1 makes the assembly between the hub unit 2 and the notched harrow 1 simpler and faster. The inner ring 22 is coaxially sleeved in the integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com