Bolt clipper preventing falling off

A technology for bolt cutters and fall prevention, which is applied to hand-held metal shearing equipment, shearing devices, and shearing equipment, etc., and can solve problems such as accidental contact with bolt cutters, failure to prevent bolt cutters from floating, and falling from high altitudes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

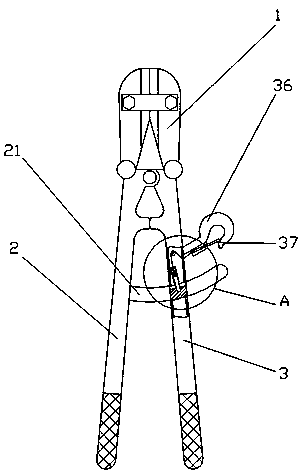

[0022] Such as Figure 1 to Figure 3 As shown in , a fall arrest bolt cutter consisting of

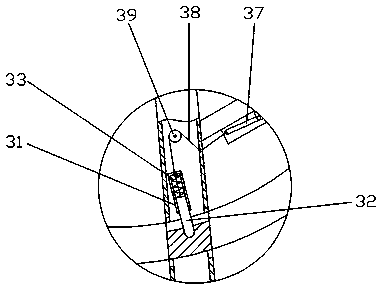

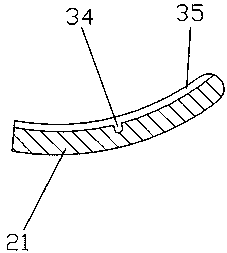

[0023] Pliers head 1, first tongs arm 2 and second tongs arm 3, the first tongs arm is hinged with the second tongs arm, described first tongs arm is provided with linkage rod 21, and second tongs arm is provided with for linkage rod Through the relief hole, the linkage rod passes through the relief hole. The linkage rod is in the shape of a circular arc. The hinge point of the first tong arm and the second tong arm coincides with the center of the linkage rod to ensure that the linkage rod can fit in the relief hole. Shuttle back and forth smoothly, not prone to jamming, the linkage rod is located on the end of the first tong arm close to the pliers head, which can reduce the size of the linkage rod. A guide sleeve 31 and a positioning pin 32 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com