Upconversion luminescence selectively enhanced upconversion luminescent material and preparation method thereof

A luminescent material and selective technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve problems such as difficult integration, complicated preparation, and inflexible operation, and achieve localized electric field enhancement, improved utilization efficiency, and enhanced up-conversion glowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

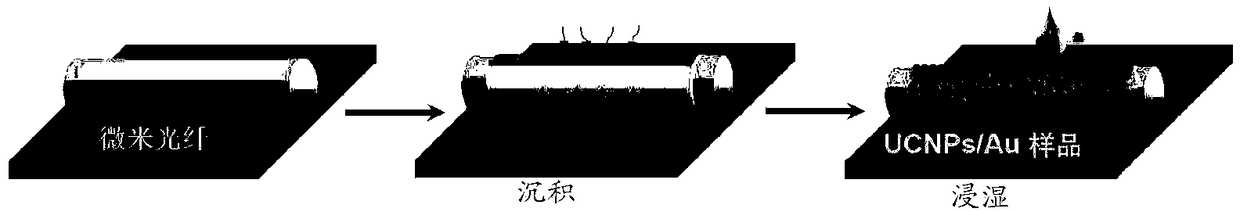

[0035] The present invention also provides a preparation method of the above-mentioned up-conversion luminescent material with enhanced up-conversion luminescence selectivity, comprising the following steps:

[0036]Depositing a layer of gold nano film on the surface of the micron optical fiber glass core, soaking the surface of the gold nano film with an up-conversion nano particle solution, and drying to obtain an up-conversion luminescent material with enhanced up-conversion luminescence selectivity.

[0037] In the present invention, the deposition method is preferably sputter coating. In the present invention, the sputtering current of the sputter coating is preferably 10-20 mA, more preferably 15 mA, and the sputtering time is preferably 1-5 min, more preferably 2 min. In the present invention, the sputter coating equipment is preferably an ETD2000 / 3000 sputter coating machine.

[0038] In the present invention, the concentration of the up-conversion nanoparticle soluti...

Embodiment 1

[0044] 1) Use a fiber stripper to strip the buffer layer and the polymer interlayer of the optical fiber to obtain the fiber core; then clamp one end of the fiber core with tweezers and place it in the outer flame of an alcohol blowtorch for 1 minute to reach its melting point, then slowly pull the tweezers to pull The fiber is stretched until the diameter is reduced to 3 microns to obtain a micron optical fiber glass core.

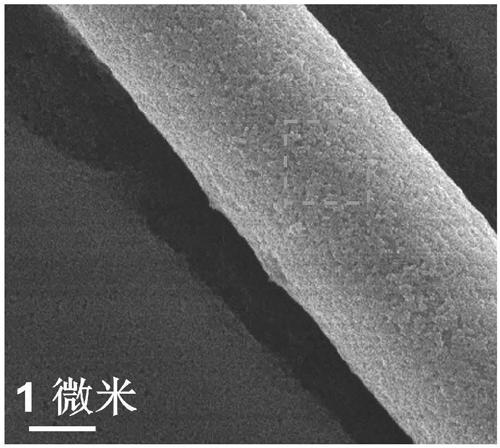

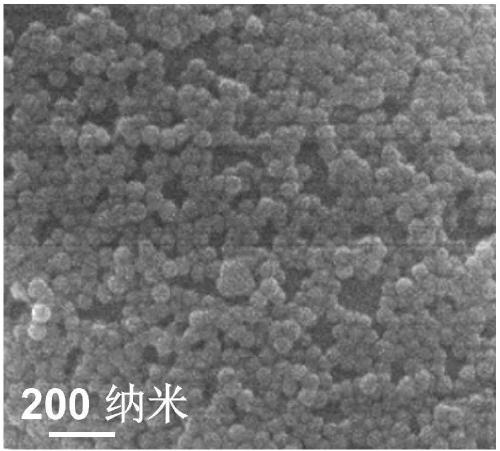

[0045] 2) Fix the prepared micron optical fiber on the glass substrate, place it in the ETD 2000 / 3000 sputter coater, set the sputtering current and sputtering time to 15 mA and 2 minutes respectively, and the gold nano film It was successfully deposited on the surface of the micron optical fiber with a thickness of 18 nanometers.

[0046] 3) Take out the sample in step 2) and place it on the experimental bench, use a syringe to convert the aqueous solution of nanoparticles into hexagonal (β) phase NaYF 4 :Yb 3+ ,Er3 + Nanoparticles (NaYF 4 / Yb / Er=78:...

Embodiment 2

[0057] 1) Use a fiber stripper to strip the buffer layer and the polymer interlayer of the optical fiber to obtain the fiber core; then clamp one end of the fiber core with tweezers and place it in the outer flame of an alcohol blowtorch for 1 minute to reach its melting point, then slowly pull the tweezers to pull The fiber is stretched until the diameter is reduced by 3 micrometers to obtain a micrometer optical fiber glass core.

[0058] 2) Fix the prepared micron optical fiber glass core on the glass substrate, place it in the ETD2000 / 3000 sputter coater, set the sputtering current and sputtering time to 15 mA and 1 minute respectively, the gold nanometer The thin film was successfully deposited on the surface of the micron optical fiber with a thickness of 10 nanometers.

[0059] 3) Take out the sample in step 2) and place it on the experimental bench, use a syringe to convert the aqueous solution of nanoparticles into hexagonal (β) phase NaYF 4 :Yb 3+ ,Er3 + Nanoparti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap