Textile feeding device facilitating roller switching

A feeding device, convenient switching technology, applied in textiles, textiles, papermaking, looms, etc., can solve the problems of troublesome process, broken textile threads, inconvenient operation, etc., to achieve convenient replacement, conducive to production operations, and convenient human control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

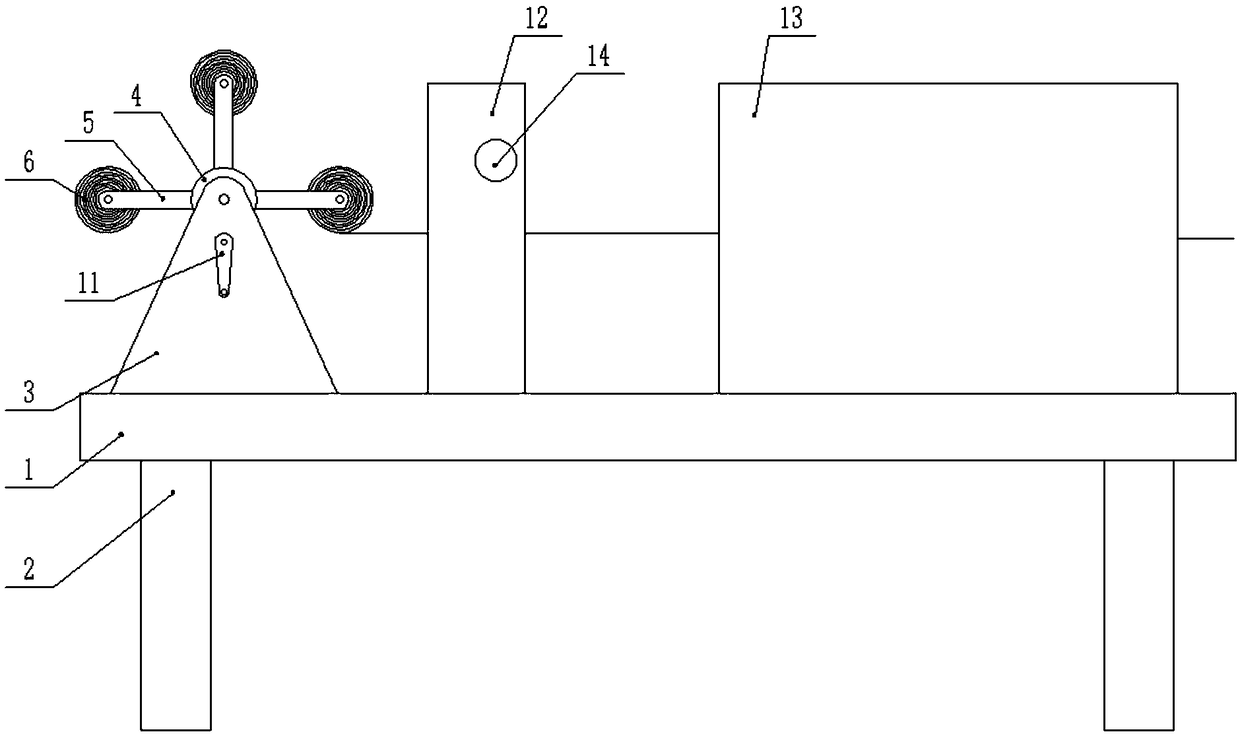

[0027] see figure 1 , a textile feeding device for conveniently switching material rollers, comprising an equipment platform 1, the four corners of the bottom end of the equipment platform 1 are fixedly connected to the legs 2, and one end of the top surface of the equipment platform 1 is fixedly connected to the feed frame 3, The feed frame 3 is rotatably connected to the rotating shaft 4, and the rotating shaft 4 is fixedly connected with a plurality of poles 5, and the end of the pole 5 away from the rotating shaft 4 is rotated and connected to the coil roll 6, and the rotating shaft 4 is connected to the feed frame. 3 is provided with a switching mechanism, and one side of the feed frame 3 is provided with a speed regulating device 12 .

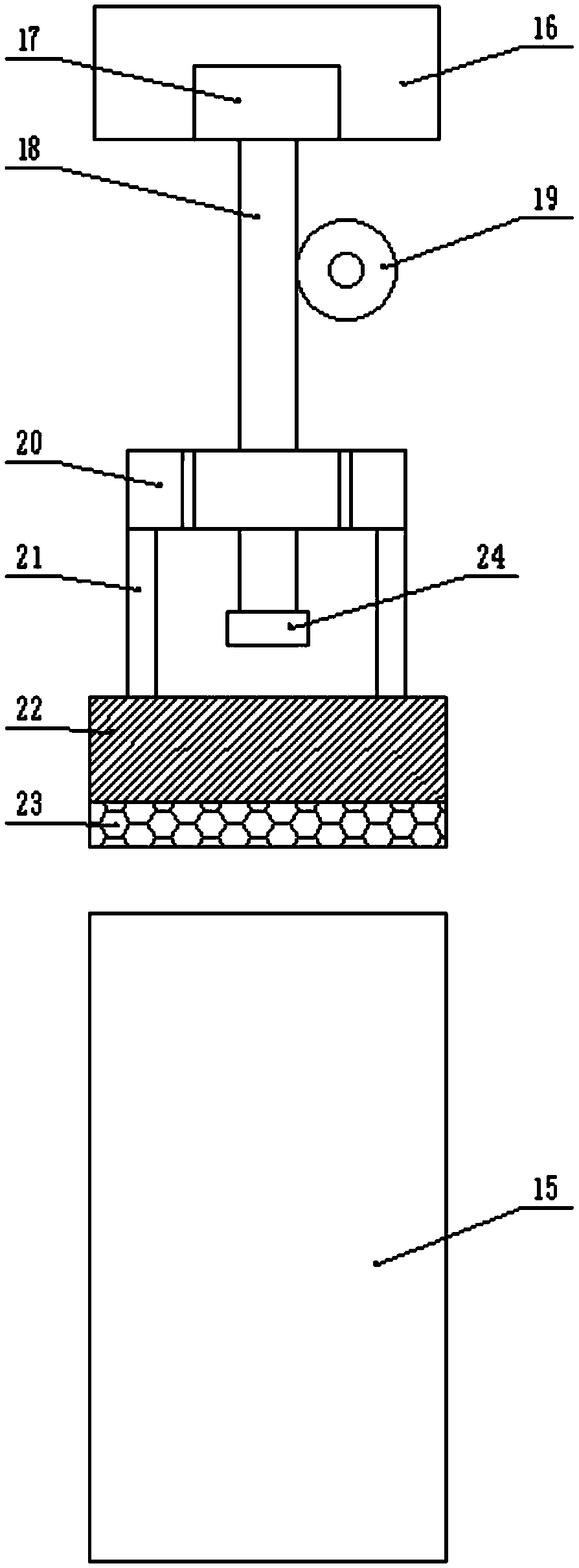

[0028] see figure 2 , the speed regulating device 12 includes a speed regulating casing, the bottom of the speed regulating casing is fixedly connected to the base 15, the top of the speed regulating casing is fixedly connected to the t...

Embodiment 2

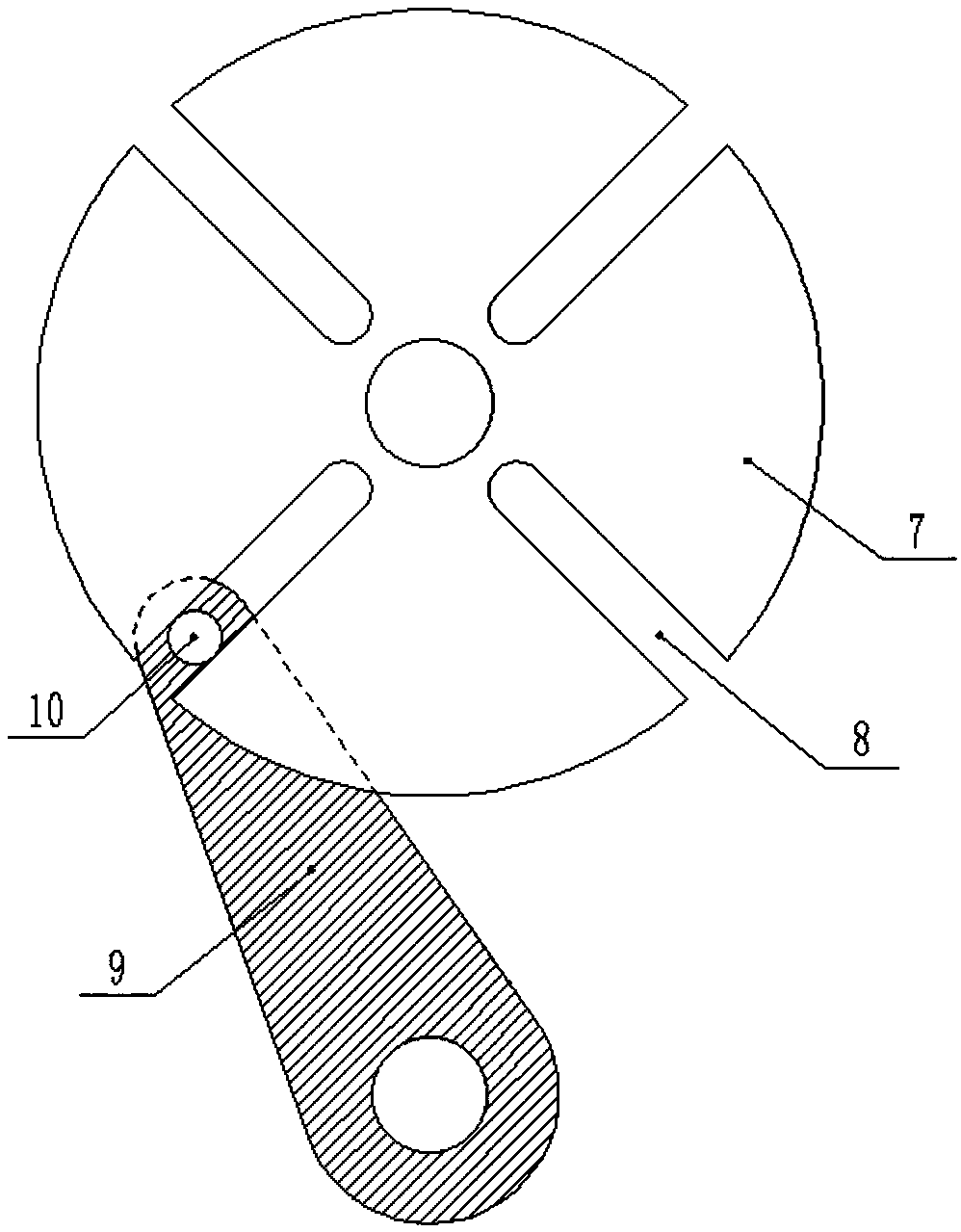

[0031] see Figure 4 , the other content of this embodiment is the same as that of Embodiment 1, except that: both sides of the feed frame 3 are provided with locking mechanisms, and the locking mechanisms include locking rods fixedly connected to both sides of the feed frame 3 25 , the locking rod 25 passes through and is threadedly connected with a locking bolt 26 , and the support rod 5 is provided with a locking groove 27 corresponding to the locking bolt 26 .

[0032] During the implementation of the present invention, the winding roller 6 winds or releases the cloth. When the winding roller 6 needs to be replaced, the crank handle 11 is shaken once, and the crank handle 11 drives the rotating plate 9 to rotate, so that the switching disk 7 rotates. At forty-five degrees, the fast switching of the winding roller 6 is carried out to facilitate the production and processing work, and when the conveying speed of the cloth needs to be controlled, the adjustment wheel 14 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com