Method used for underground construction side wall and bottom plate water seepage treatment

A technology for underground engineering and treatment methods, applied in water conservancy engineering, infrastructure engineering, artificial islands, etc., to prevent damage, facilitate subsequent construction, and have low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] This embodiment provides a water seepage treatment method for the side wall and bottom plate of underground engineering;

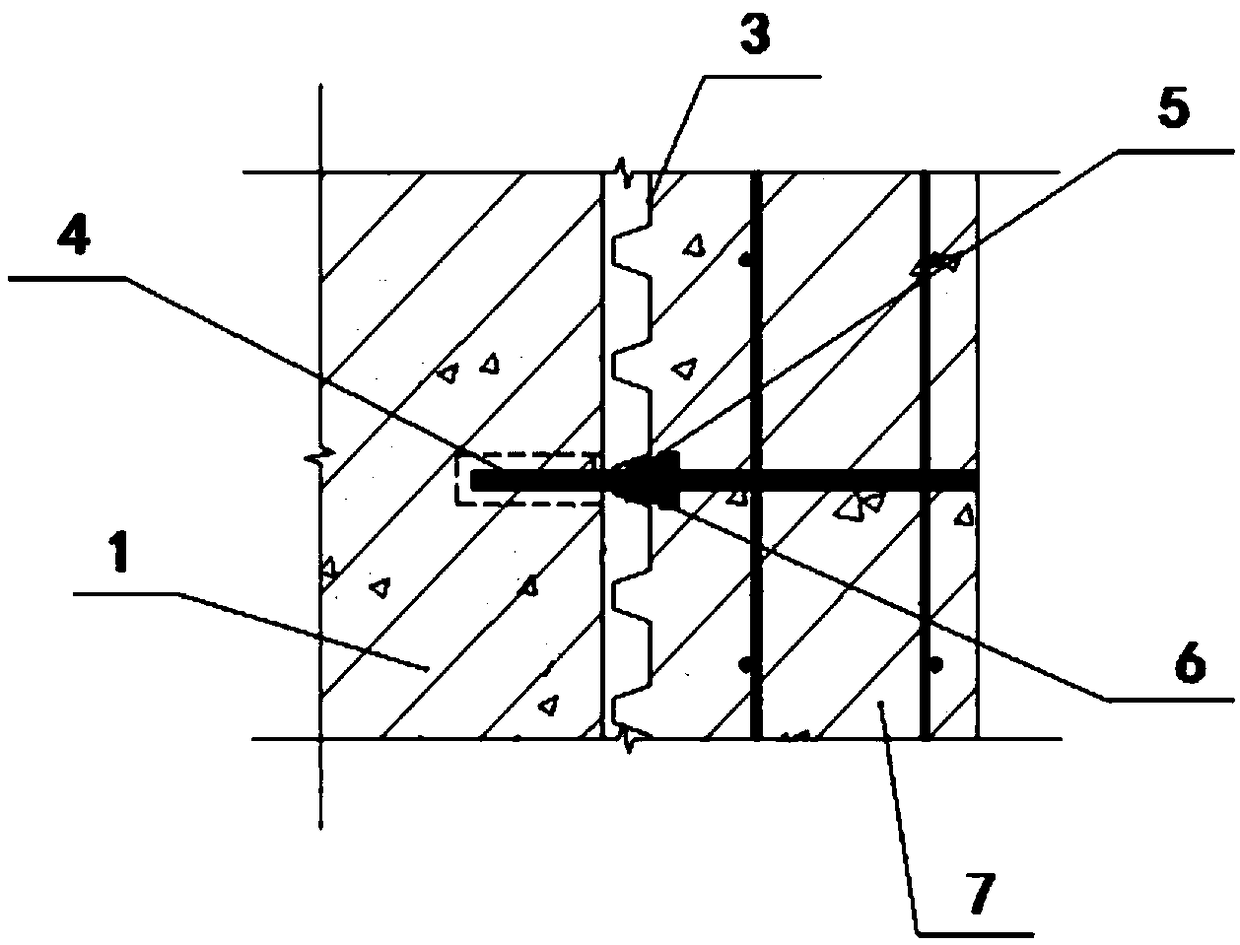

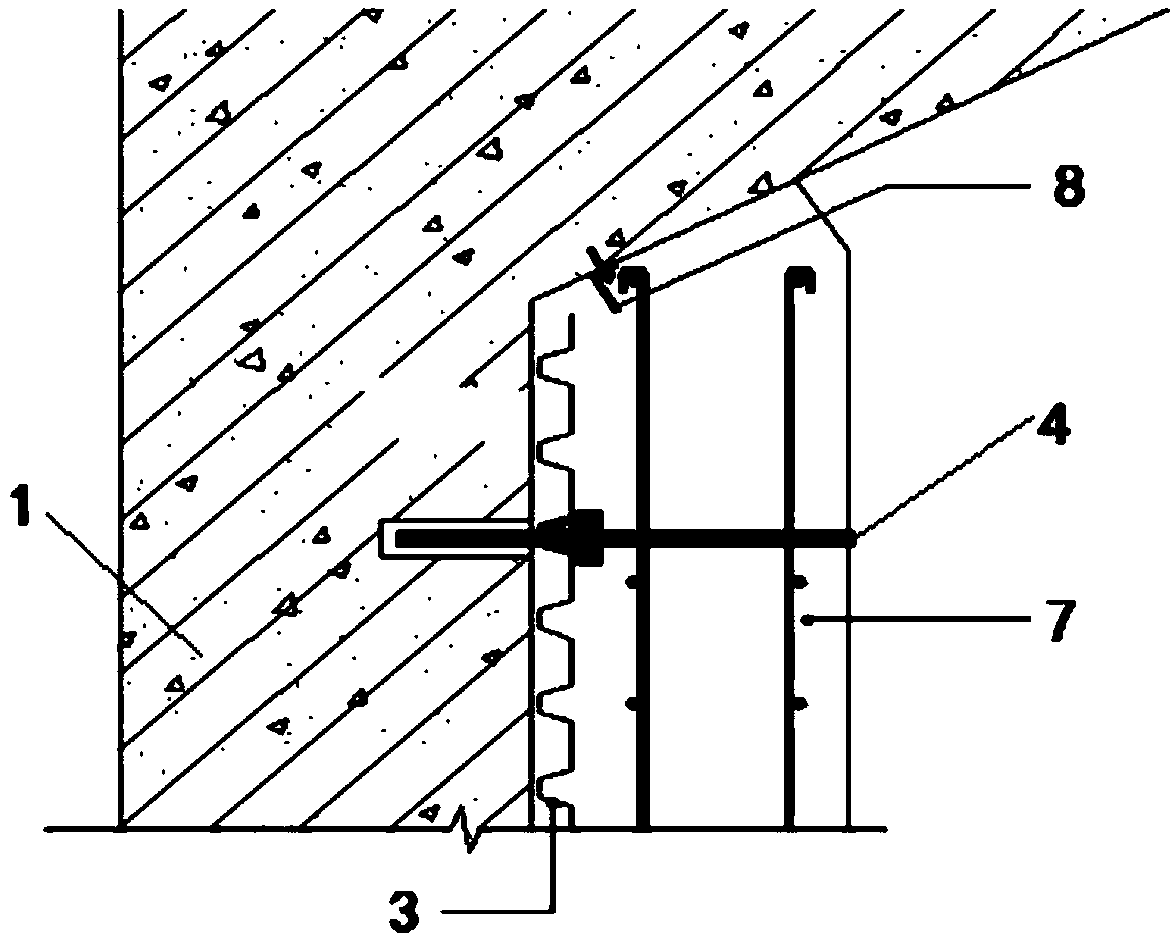

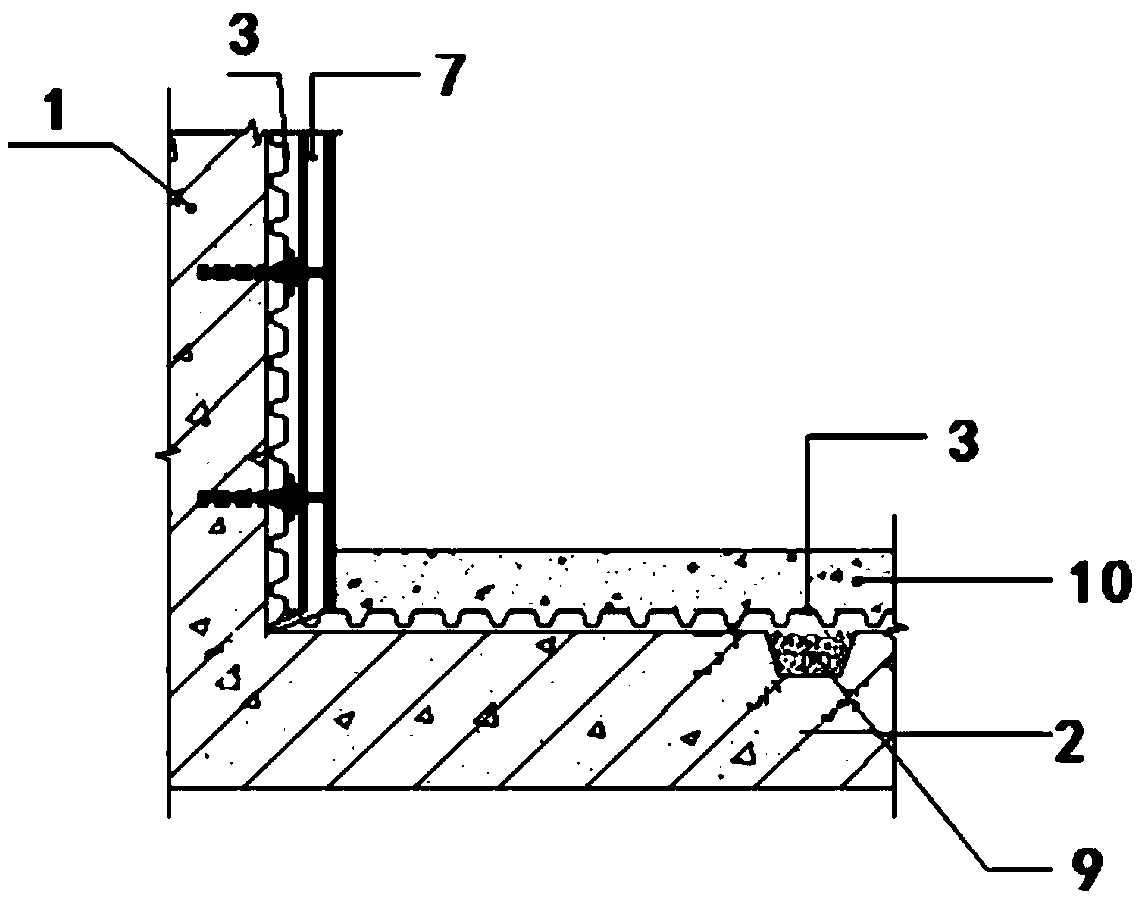

[0037] Such as Figure 1-Figure 3 and Figure 8 As shown, the water seepage treatment method for the underground engineering side wall and bottom plate in the present embodiment includes the following steps:

[0038] a. After plugging the cracks in side wall 1 and bottom plate 2, clean them up;

[0039] b. Lay the water delivery board 3 on the side wall 1 and the bottom plate 2 after cleaning, and connect the water delivery board with the drainage system of the underground project;

[0040] c. Pour the laid water delivery board 3 to cover the concrete layer.

[0041]The present invention plugs the seepage of the cracks on the side wall and the bottom plate first, which can greatly reduce the water output of the cracks, and at the same time facilitate subsequent construction; The drainage system of the underground project is connected to facilita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com