Zoom lens structure suitable for high-magnification lens

A zoom lens, high magnification technology, used in installation, optics, instruments, etc., can solve the problems of difficult to find the lens out of step and idling, the motor structure has become a chicken rib, redundant focus step table, etc., to improve the service life and durability. Sensitive, fast and precise adjustment of the effect of the control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

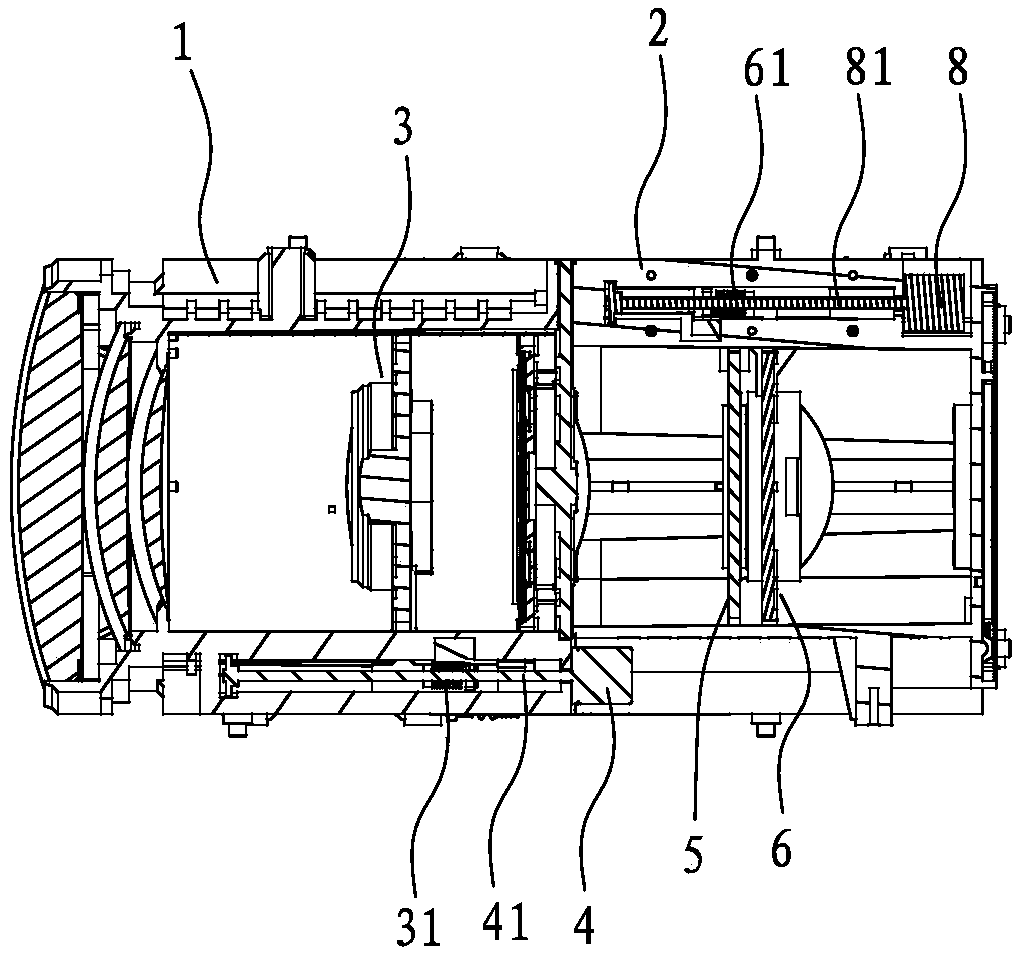

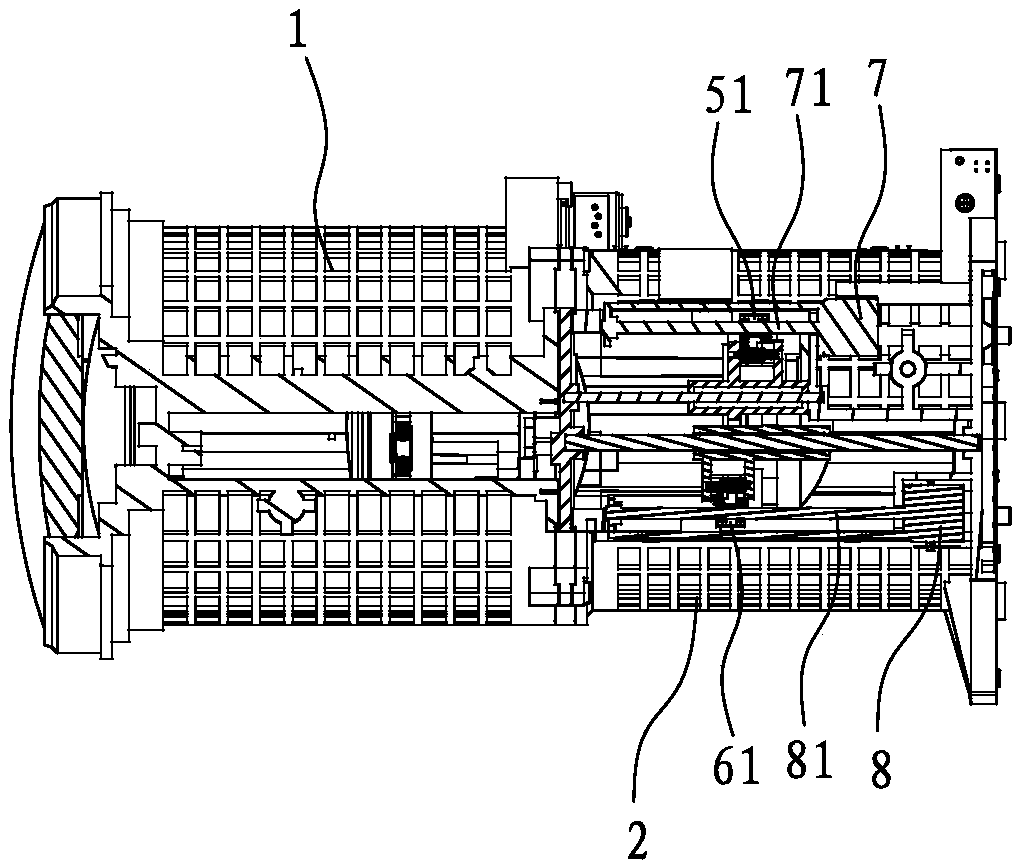

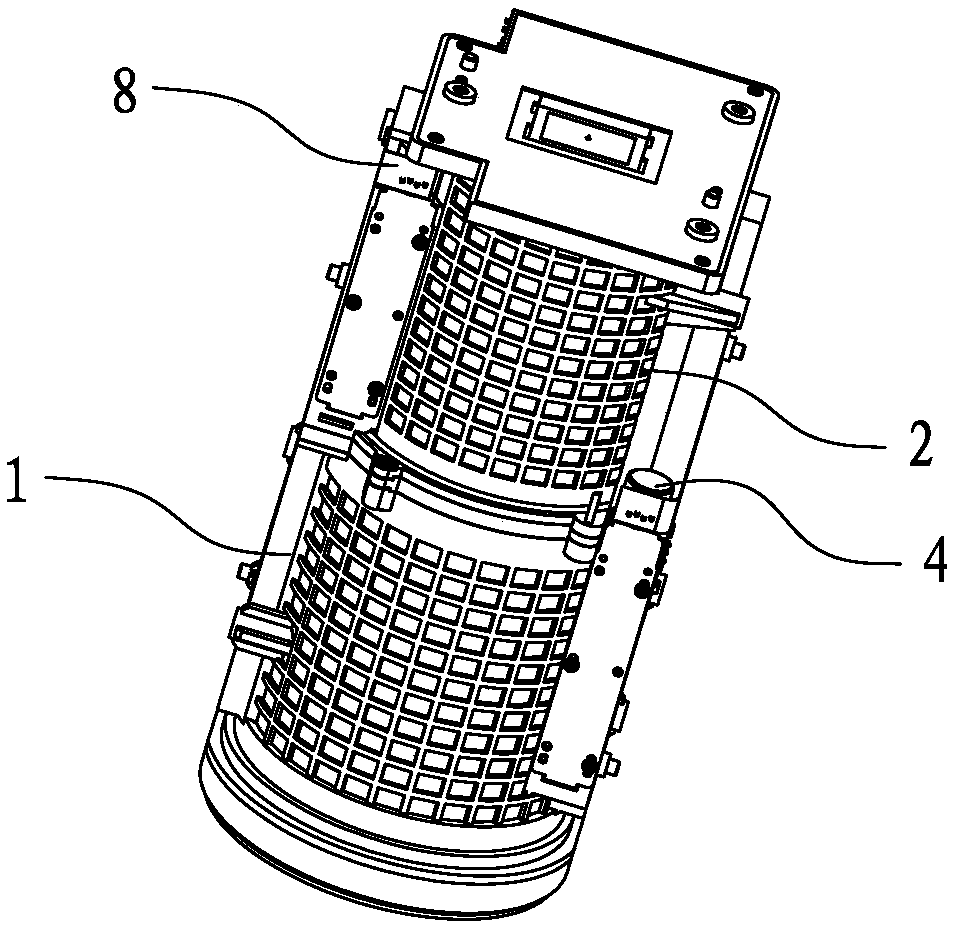

[0020] Such as Figure 1 to Figure 4 A zoom lens structure suitable for high-magnification lenses is shown, including a front lens barrel 1 and a rear lens barrel 2, and the front lens barrel 1 is provided with a focus lens group 3 that can slide therein, and the focus lens The group 3 is fixed with a first nut 31, the front lens barrel 1 is provided with a focus motor 4, and the focus motor 4 is fixed with a first screw 41 threadedly connected with the first nut 31, and the rear lens barrel 2 The first zoom lens group 5 and the second zoom lens group 6, which are independent of each other, are slidably connected in the front and rear directions, and the first zoom lens group 5 and the second zoom lens group 6 are respectively fixed with a second nut 51 and a third nut. nut 61, the rear lens barrel 2 is provided with a first zoom motor 7 and a second zoom motor 8, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com