Intelligent detection system and method for spray paint surface defects

A technology of intelligent detection and defect detection, which is applied in the direction of optical defect/defect detection, image data processing, image enhancement, etc. It can solve the problems of low accuracy, delay in production efficiency, time-consuming and labor-intensive problems, so as to improve efficiency and save material and manpower , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

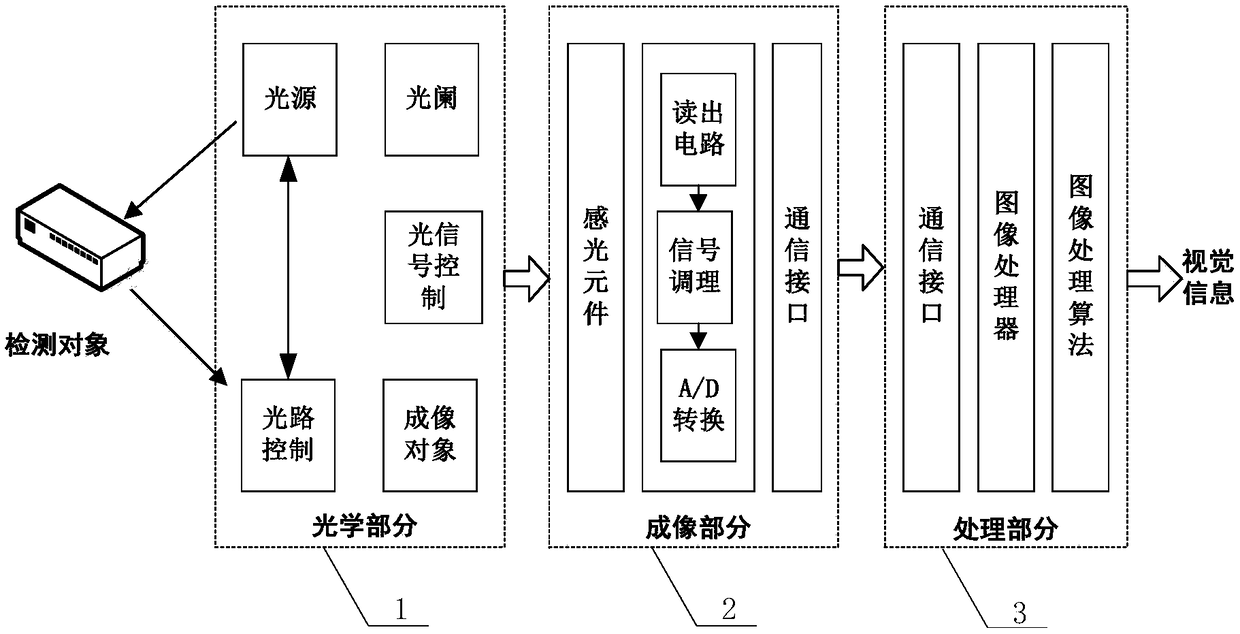

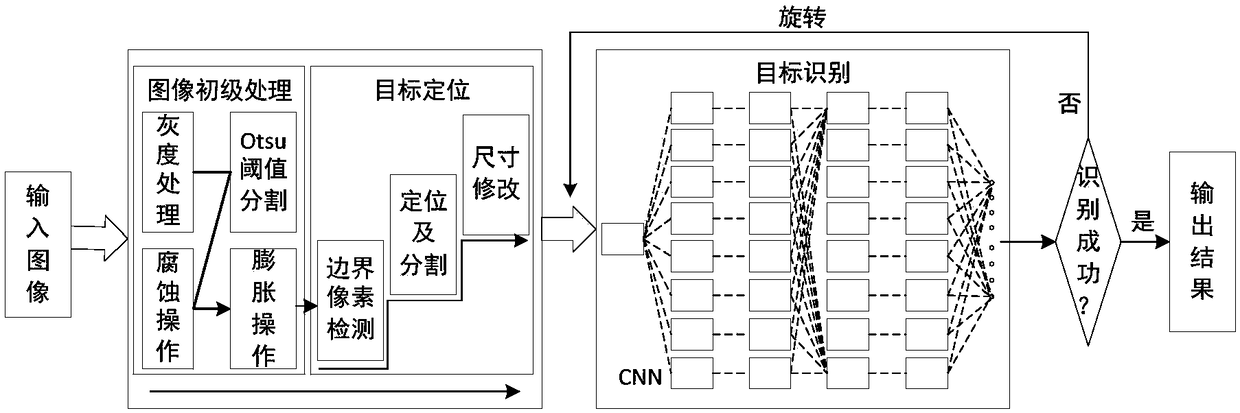

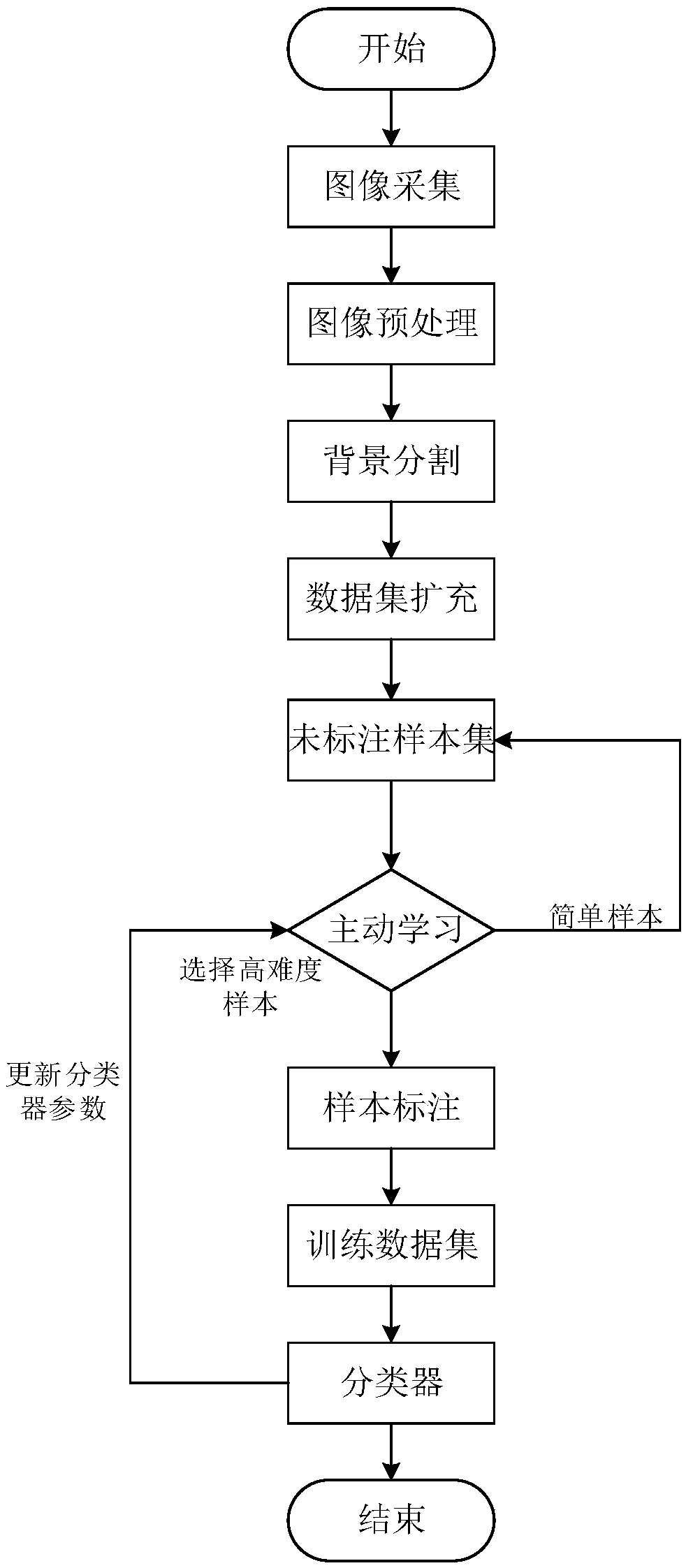

[0041] see Figure 1-Figure 3 as shown, figure 1 A schematic diagram of the image acquisition module provided in this embodiment; figure 2 The frame diagram of the fast visual recognition and positioning algorithm based on deep learning provided in this embodiment; image 3 A schematic flow chart of the intelligent detection method for paint surface defects provided in this embodiment.

[0042] The intelligent detection system of the spray paint surface defect provided by the present embodiment includes an image acquisition module, an image positioning module and a defect detection module; wherein: the image acquisition module uses a digital camera to collect multi-angle image information of the detected object; the image positioning module is based on The machine vision method is used to distinguish the target from the background; the defect detection module is used to detect whether there are multiple defects in the target. Wherein, the machine is, for example, a compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com