Numerical control manufacturing machine tool for assembling cables and cable assembling method

A technology for cables and machine tools, applied in the field of CNC production of machine tools and cable assembly, can solve the problems of factory prefabrication of cable assembly components, complete distribution of cable assembly components, and low level of material intensive management, so as to optimize construction. The effect of on-site management, optimization of material intensive management, and improvement of process standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

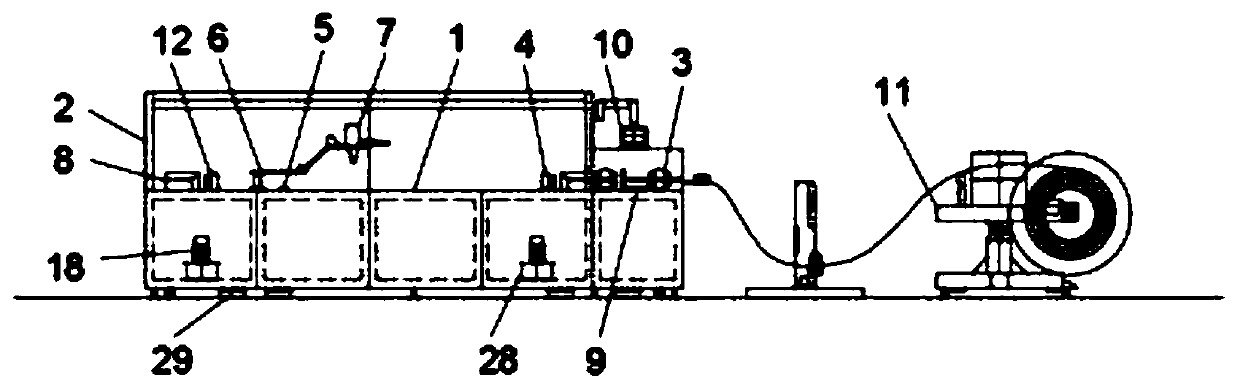

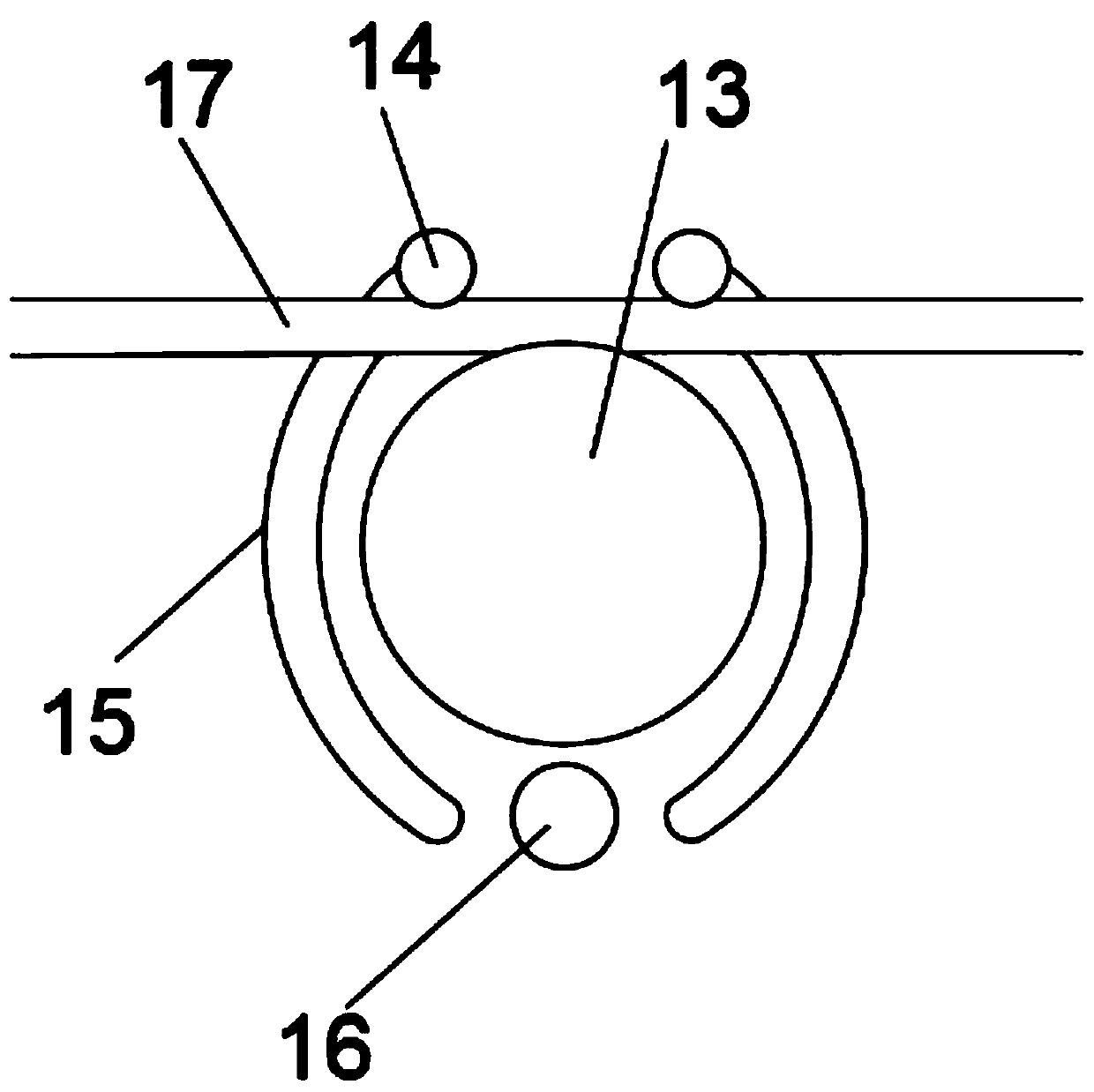

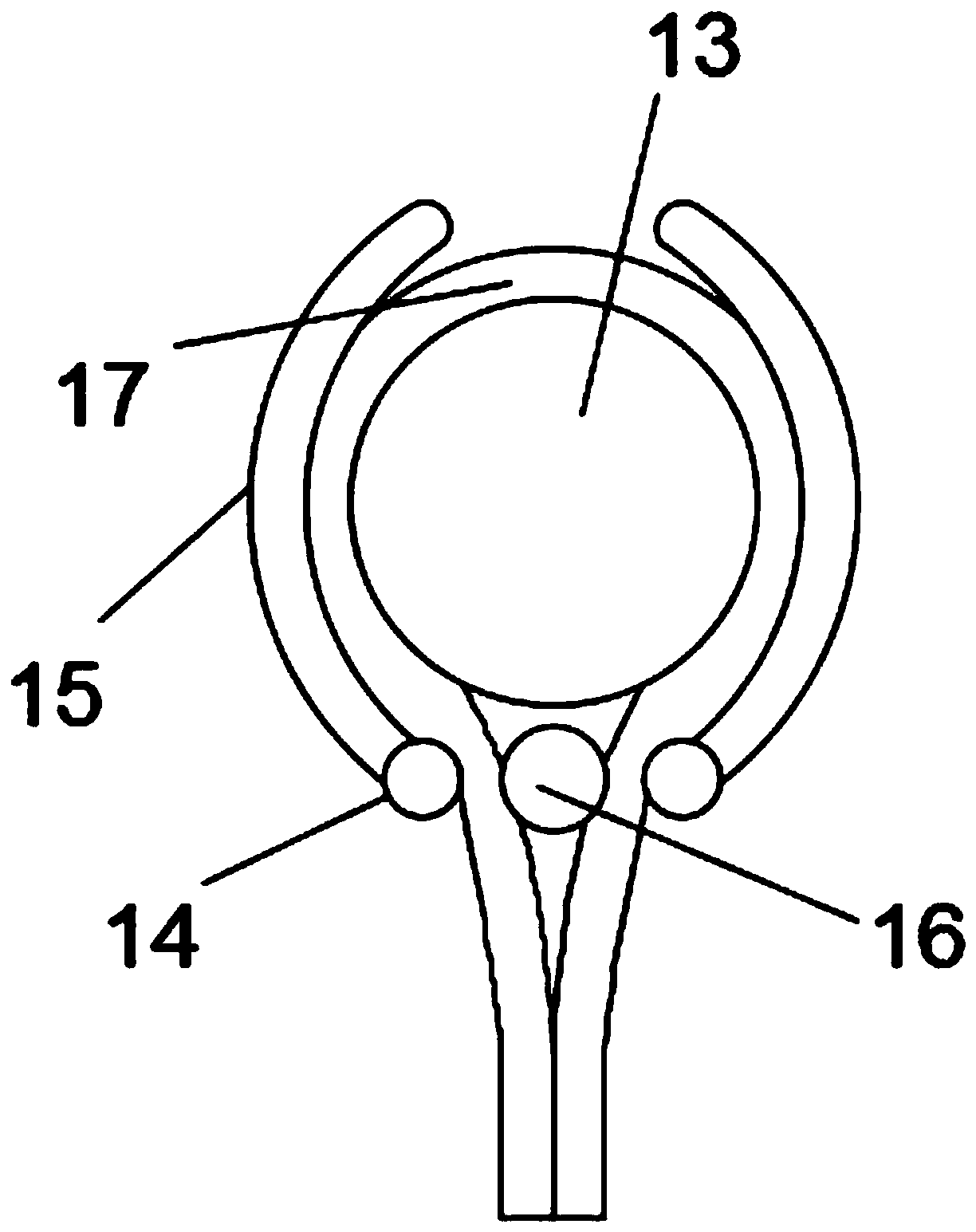

[0031] Such as figure 1 , 2 , 3, 4, and 5, a numerically controlled manufacturing machine tool for assembling cables and a cable assembling method, wherein:

[0032]A numerical control manufacturing machine tool for assembling cables, comprising a housing 2 provided with an operating table 1, one end of the housing is provided with a cable stripping and cutting unit 3, and the cable stripping and cutting unit includes several pairs of wire rollers for straightening cables and stripping and cutting tool, the operating table of the housing is provided with a cable bending device unit 4, and the operating table is also provided with a piercing wire clamp unit 5, and the piercing wire clamping unit includes a mechanical telescopic arm 6 fixedly connected to the operating table. The other end of the arm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com