A polymer plastic-steel type ladder bridge

A polymer, plastic steel technology, applied in the direction of electrical components, etc., can solve the problem that the ladder bridge can not be stretched, can not adjust the reserved length of the cable end, etc., to achieve the effect of simple structure and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

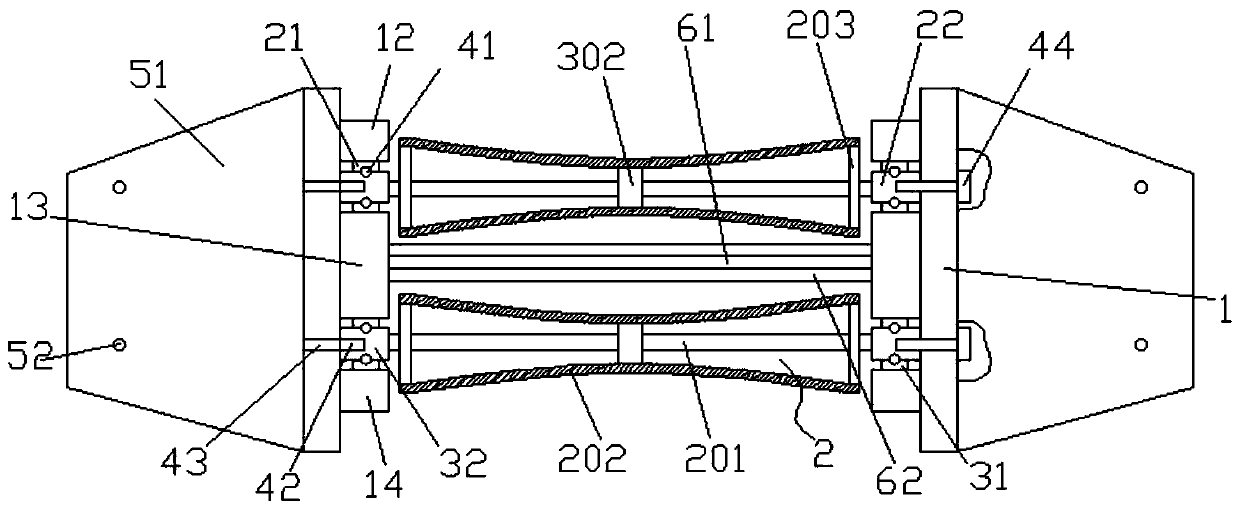

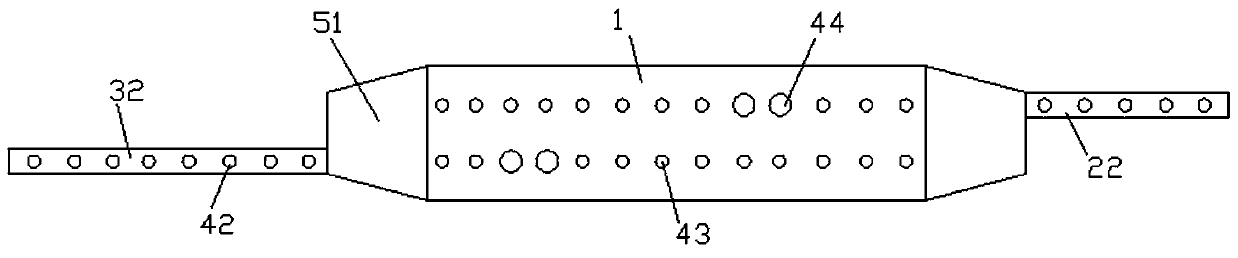

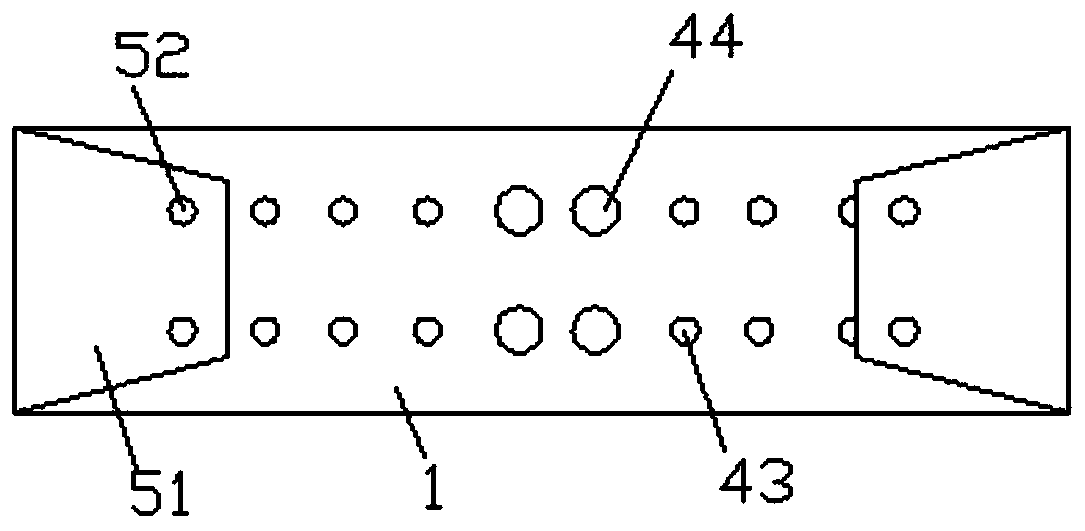

[0021] Such as figure 1 Shown; a polymer plastic-steel type ladder bridge, including two sets of ladder sides 1, and the ladder beam 2 installed in parallel between the two sets of ladder sides 1, the inner sides of the two sets of ladder sides 1 are installed with the first fixed steel 12. The second fixed steel 13, the third fixed steel 14, the adjacent surfaces between the first fixed steel 12 and the second fixed steel 13 are respectively equipped with first slide rails 21, and the two sets of first slide rails 21 are installed with First slide bar 22, ladder beam 2 is installed on the first slide bar 22 on two groups of ladder sides 1, the second slide rail 31 is installed on the adjacent surface of second fixed steel 13 and the 3rd fixed steel 14 respectively, two The second slide bar 32 is installed between the second slide rails 31 of the group, the ladder beam 2 is installed on the second slide bar 32 on the two sets of ladder sides 1, the first slide bar 22 and the t...

Embodiment 2

[0028] Such as figure 1 Shown; a polymer plastic-steel type ladder bridge, including two sets of ladder sides 1, and the ladder beam 2 installed in parallel between the two sets of ladder sides 1, the inner sides of the two sets of ladder sides 1 are installed with the first fixed steel 12. The second fixed steel 13, the third fixed steel 14, the adjacent surfaces between the first fixed steel 12 and the second fixed steel 13 are respectively equipped with first slide rails 21, and the two sets of first slide rails 21 are installed with First slide bar 22, ladder beam 2 is installed on the first slide bar 22 on two groups of ladder sides 1, the second slide rail 31 is installed on the adjacent surface of second fixed steel 13 and the 3rd fixed steel 14 respectively, two The second slide bar 32 is installed between the second slide rails 31 of the group, the ladder beam 2 is installed on the second slide bar 32 on the two sets of ladder sides 1, the first slide bar 22 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com