Method for synergistically suppressing combustion pressure pulsation by using high-frequency excitation discharge center plasma and side plasma

A plasma and high-frequency excitation technology, applied in the direction of plasma, electrical components, etc., can solve the problems of insufficient actuation frequency, mechanical loss, and large actuation time delay, and achieve stable flame shape, pressure pulsation suppression, thermoacoustic The effect of slowing down the oscillation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

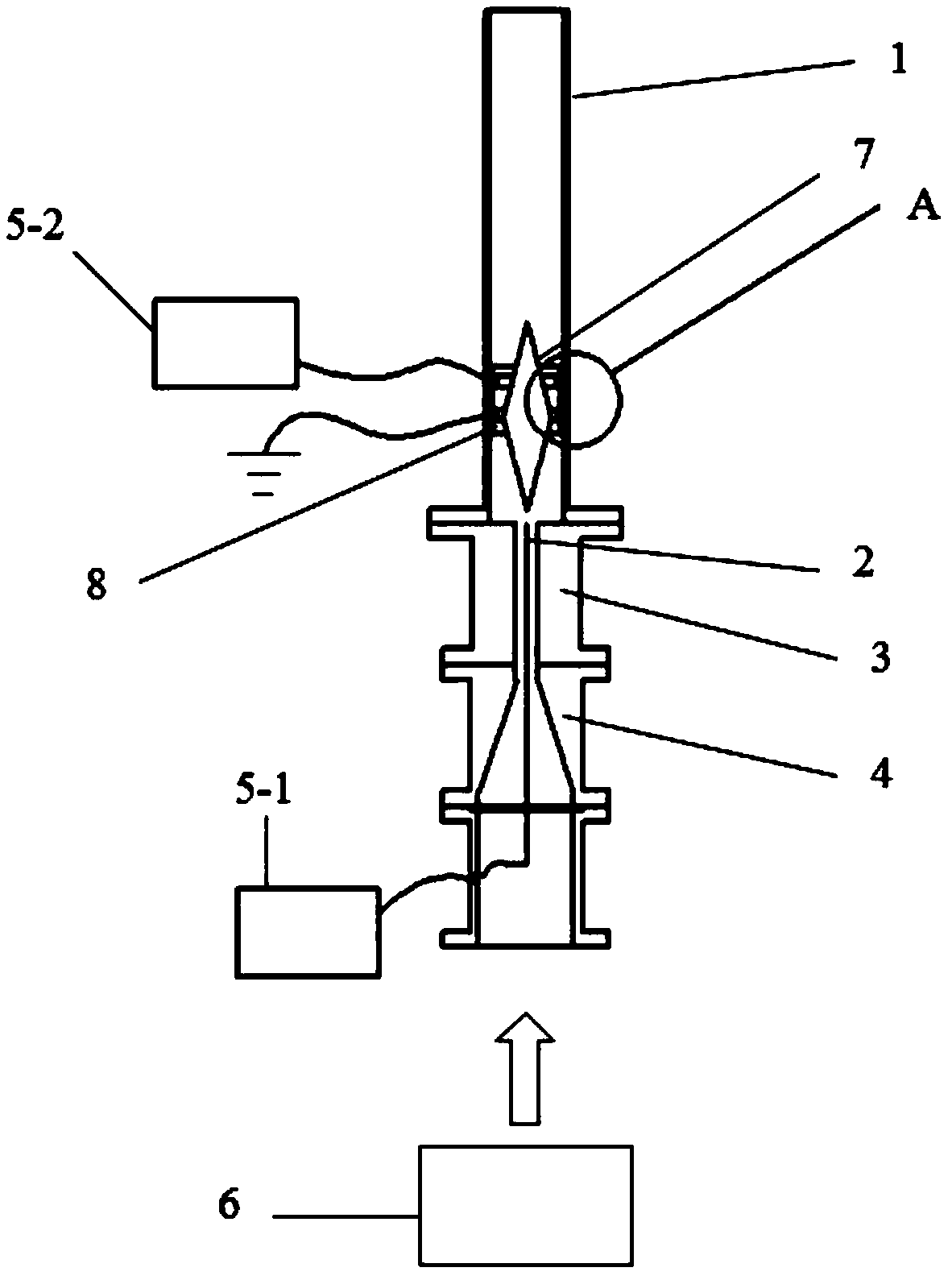

[0017] Specific Embodiment 1: This embodiment is a method for coordinating the suppression of combustion pressure pulsation by a high-frequency excitation discharge center plasma and side plasma, which is specifically carried out according to the following steps:

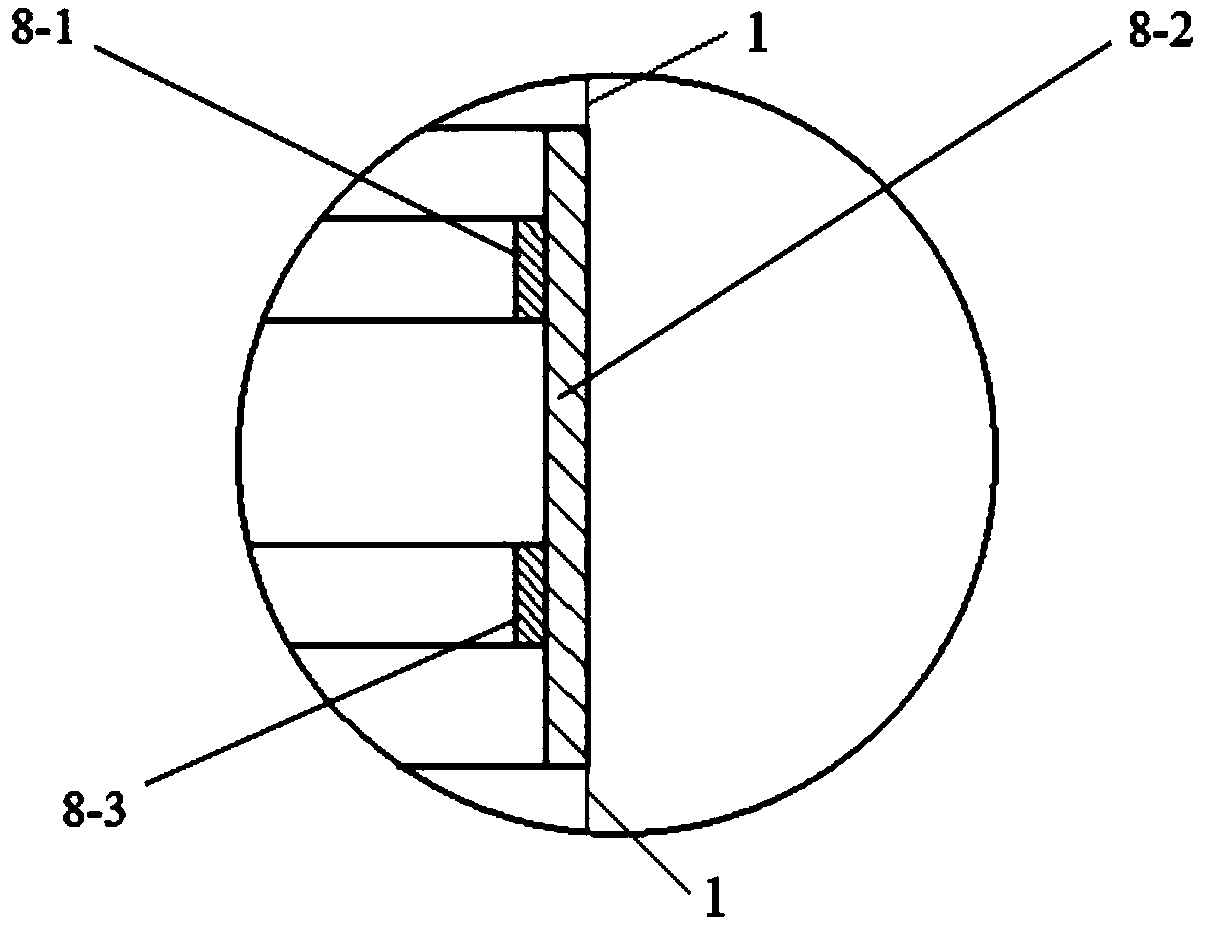

[0018] Place the metal electrode at the center of the entrance of the combustion chamber, place the ring-shaped DBD electrode on the side wall of the combustion chamber in a circle and at a height around the flame, and connect the metal electrode to the output end of the first power supply outside the combustion chamber. The ring-shaped DBD electrode is connected to the output end of the second power supply outside the combustion chamber, and the combustible premixed gas is introduced into the combustion chamber and ignited. When thermoacoustic oscillation occurs in the combustion chamber accompanied by a certain degree of pressure pulsation, the external combustion chamber is activated. The first power supply and th...

specific Embodiment approach 2

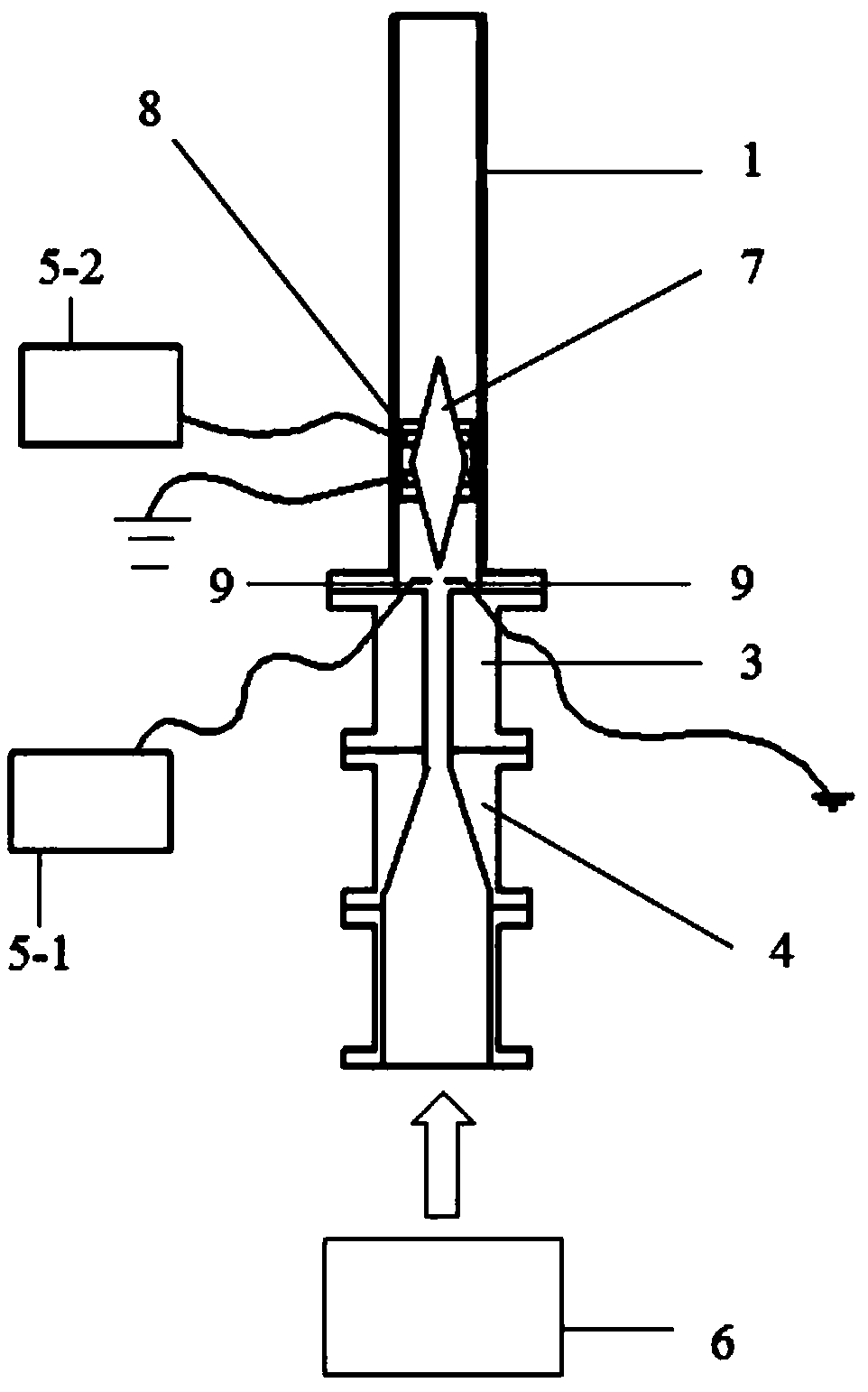

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the metal electrode is a metal suspension single electrode, and the lower end of the metal suspension single electrode is connected to the output end of the first power supply outside the combustion chamber. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the metal electrode is a metal double electrode, and a pair of metal double electrodes are installed near the root of the flame in an opposite arrangement. Each electrode is respectively connected with the output terminal of the first power supply outside the combustion chamber and the ground wire. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com