Large-scale anchor chain bar blanking production line and feeding method

A large-scale, production line technology, applied in the direction of sawing machine accessories, metal processing equipment, metal sawing equipment, etc., can solve the problems of increased production line cost, low production efficiency, slow rising speed of the entire length of bar, etc., to achieve reduction Reduce labor intensity, improve production efficiency, and achieve the effect of accurate action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

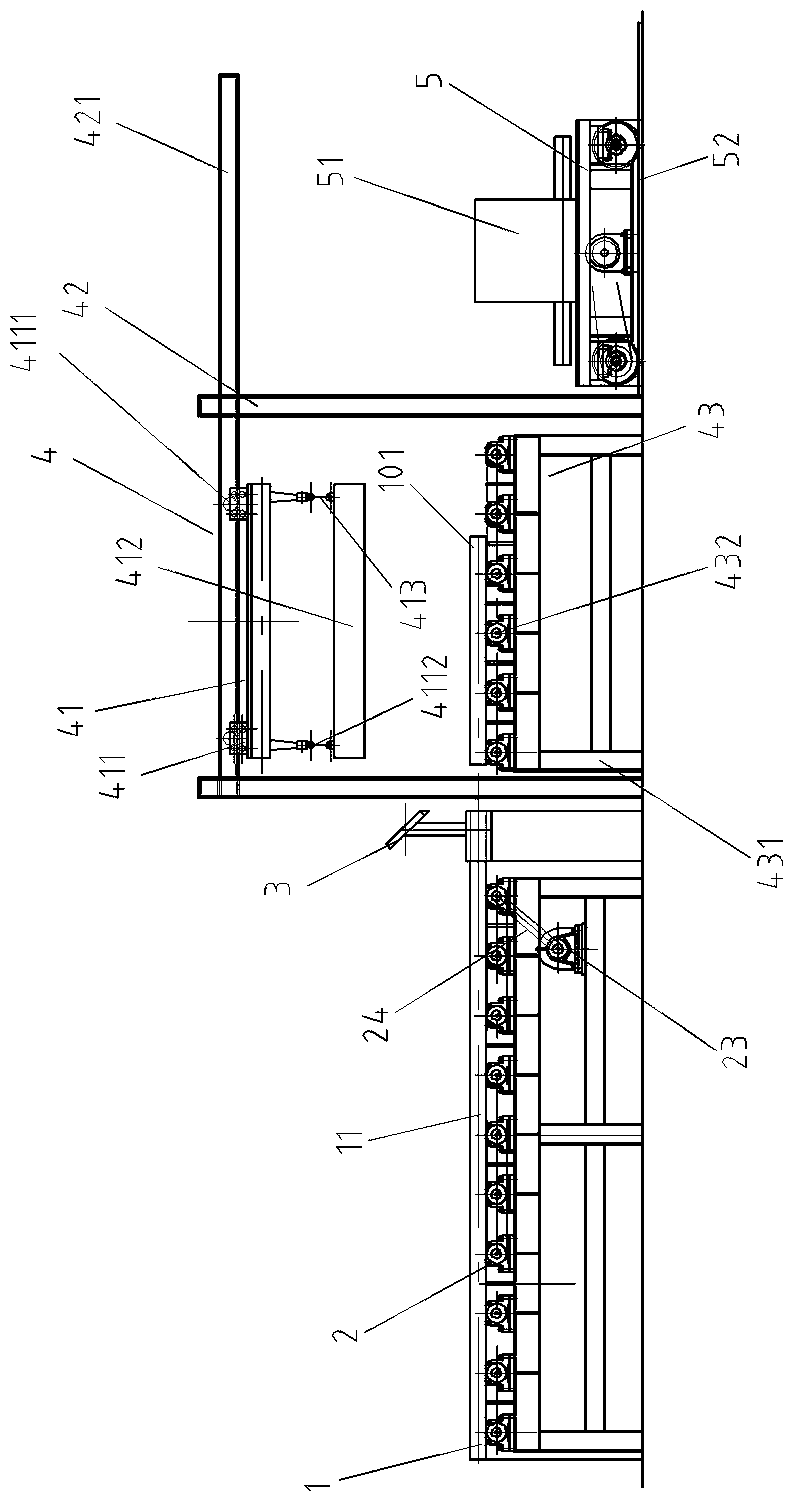

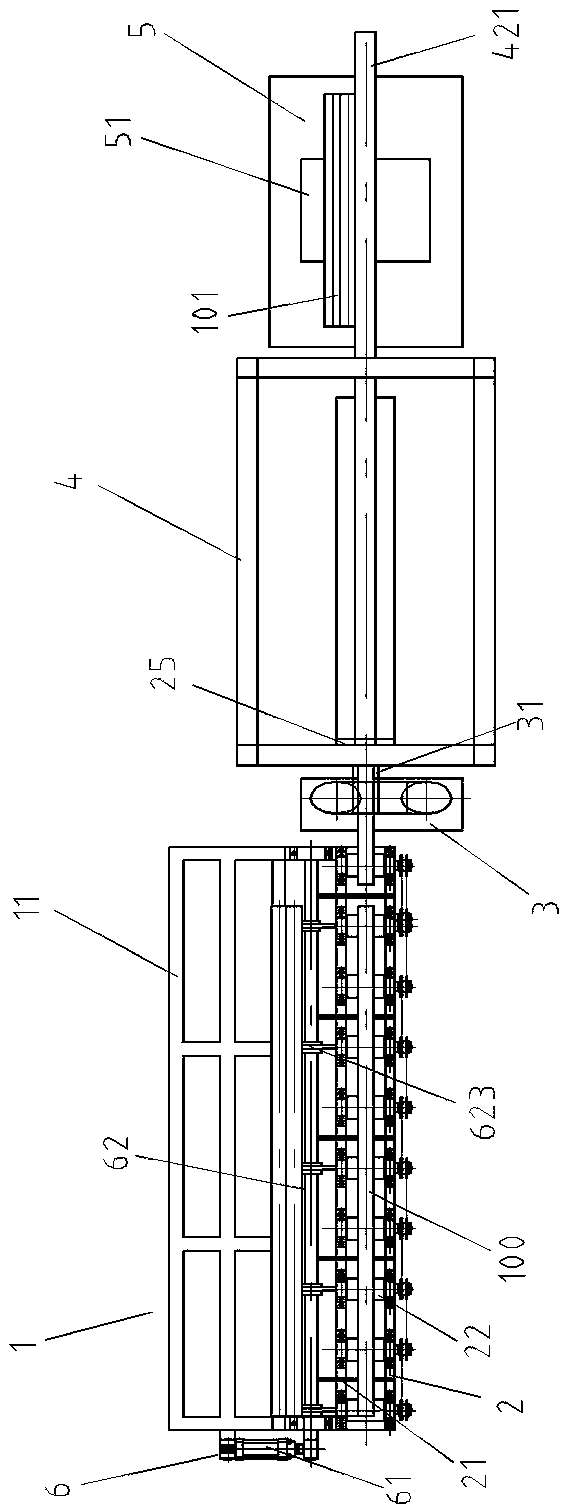

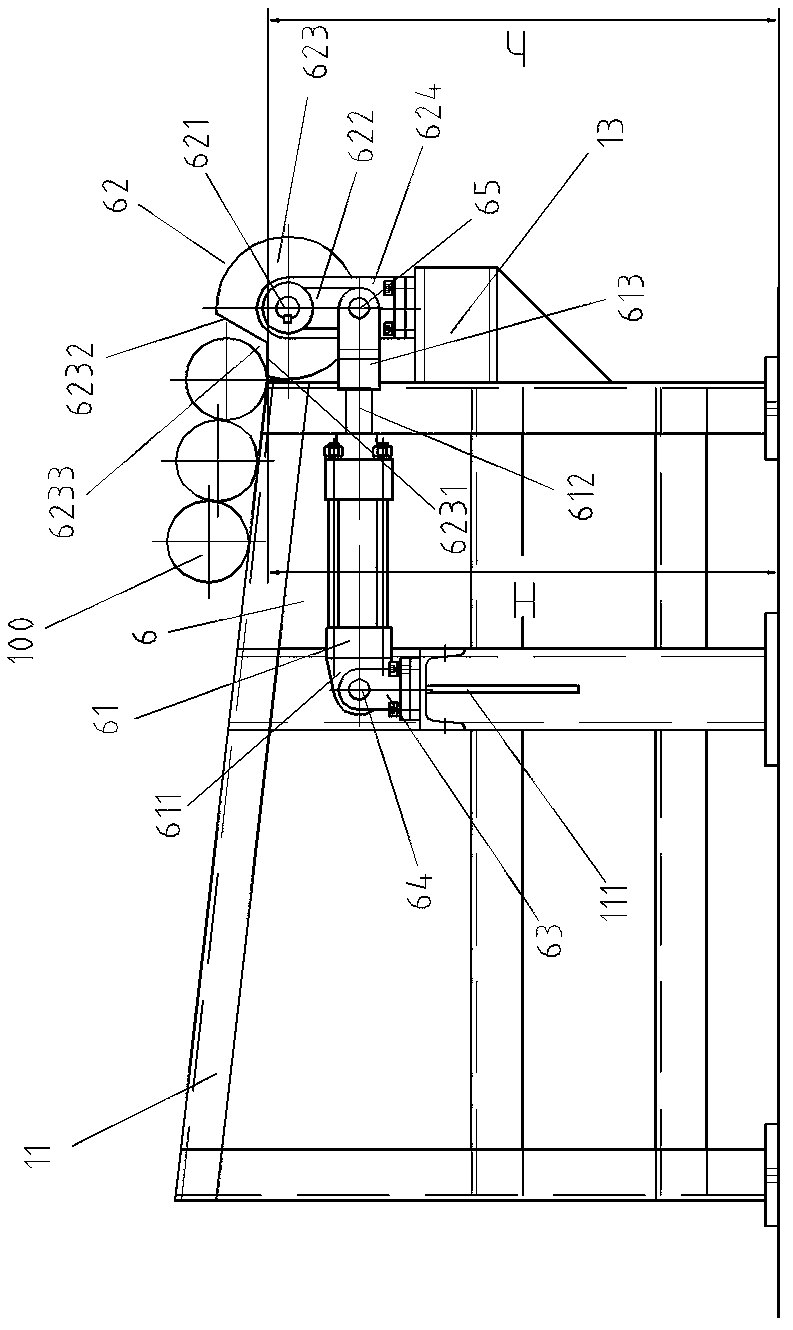

[0025] Such as figure 1 and figure 2 As shown, the large-scale anchor chain bar blanking production line in this embodiment includes a material receiving device 1, a power transport frame 2, a sawing machine 3, a lifting device 4 and an electric rail flat car 5, and the material receiving device 1 includes a bearing The material rack 11 and the material turning mechanism 6, the material receiving frame 11 and the power feeding frame 2 are arranged side by side. Such as image 3 As shown, the material receiving frame 11 is a frame structure welded by section steel, the top of which is high on the outside and low on the inside and is inclined towards the power feeding frame 2 on the adjacent side. Between the 2 longitudinals of the feeding frame.

[0026] The hoisting device 4 comprises a spreader 41, a hanger suspension frame 42 and an anchor chain bar material rece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com