Horizontal bathroom cabinet layer board separation method, control method and device

A technology of horizontal separation and bathroom cabinets, which is applied in the directions of transportation and packaging, destacking of objects, conveyors, etc., to achieve the effect of solving adhesion, avoiding accumulated errors, and eliminating accumulated errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

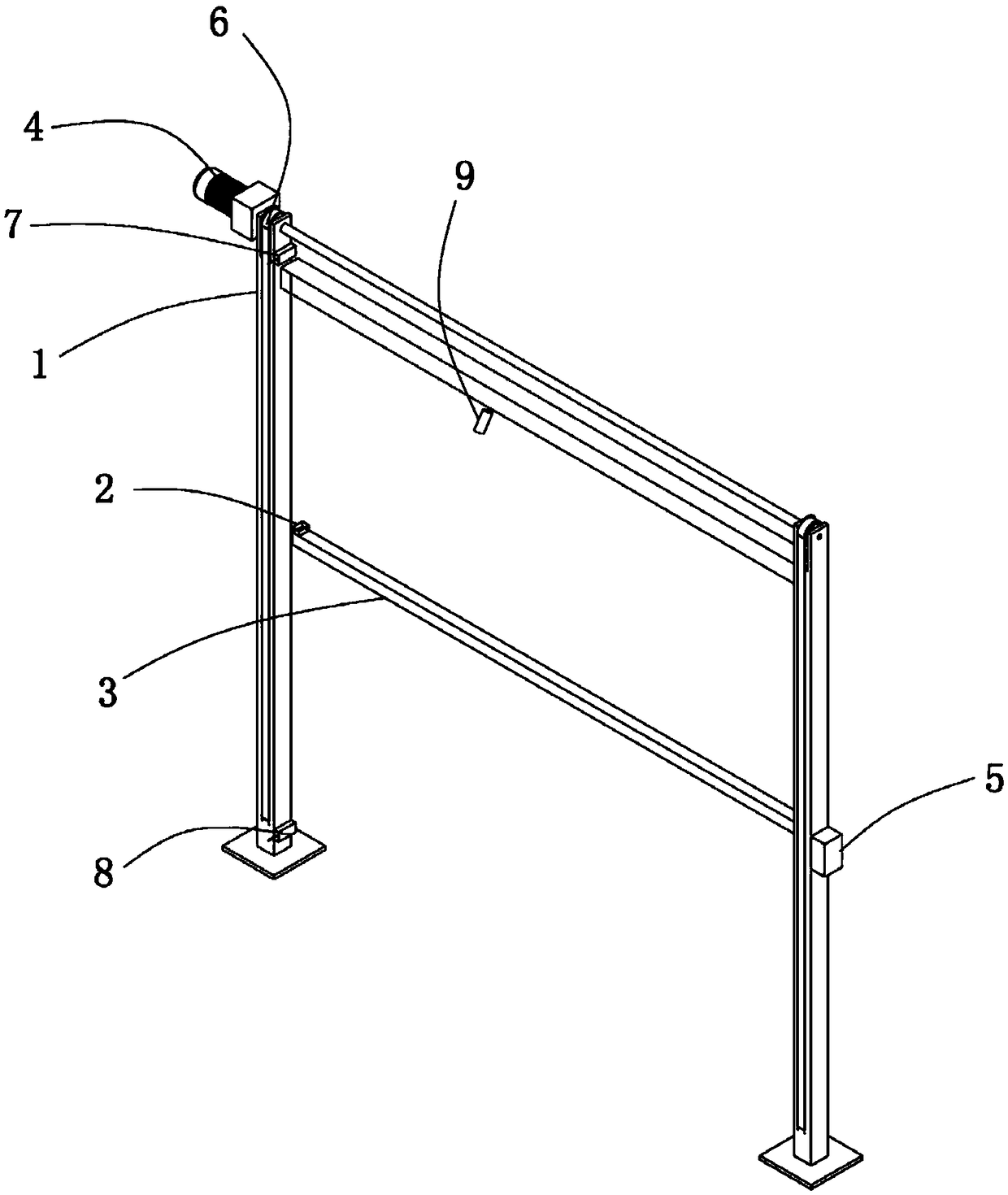

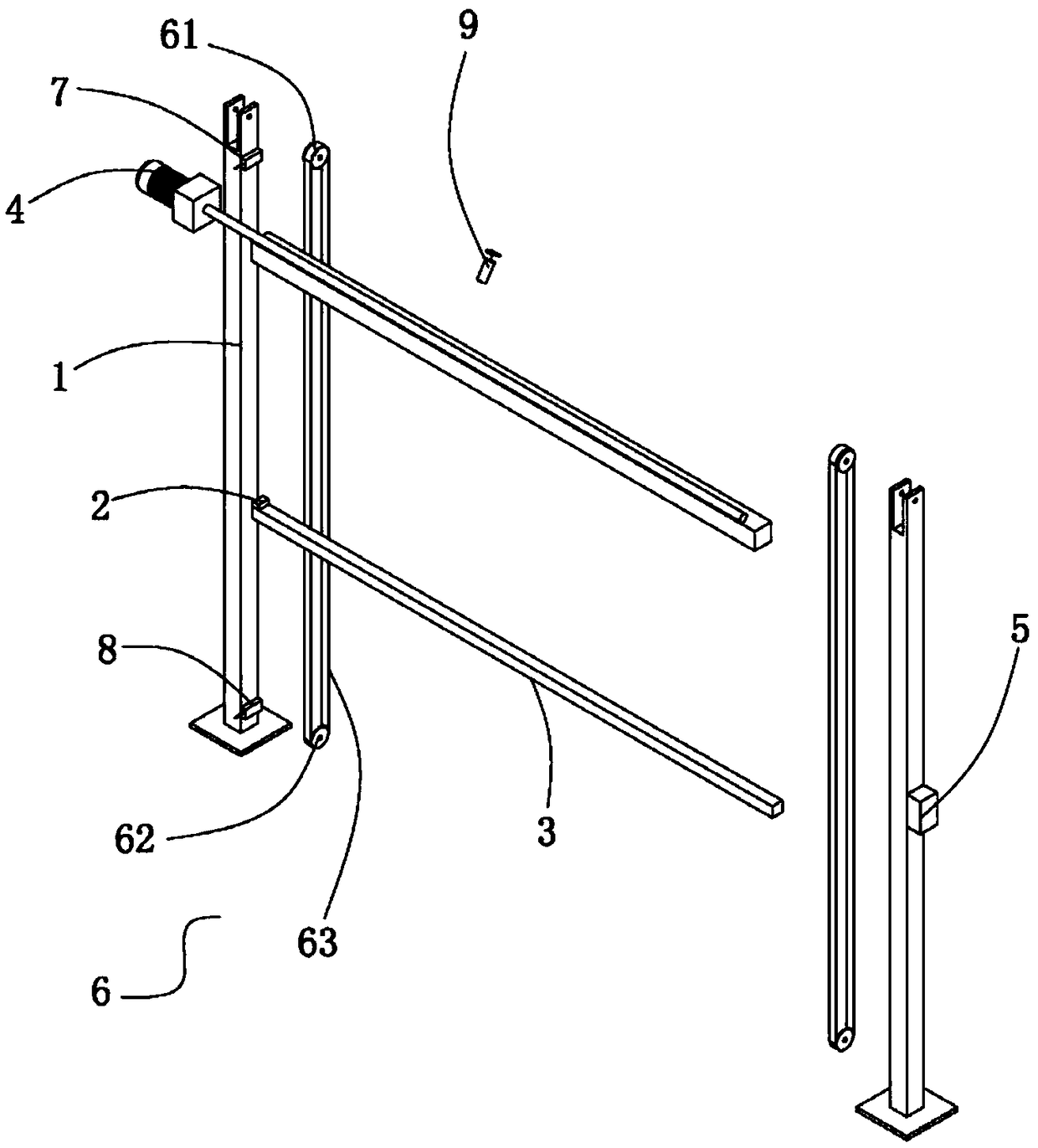

Method used

Image

Examples

Embodiment 2

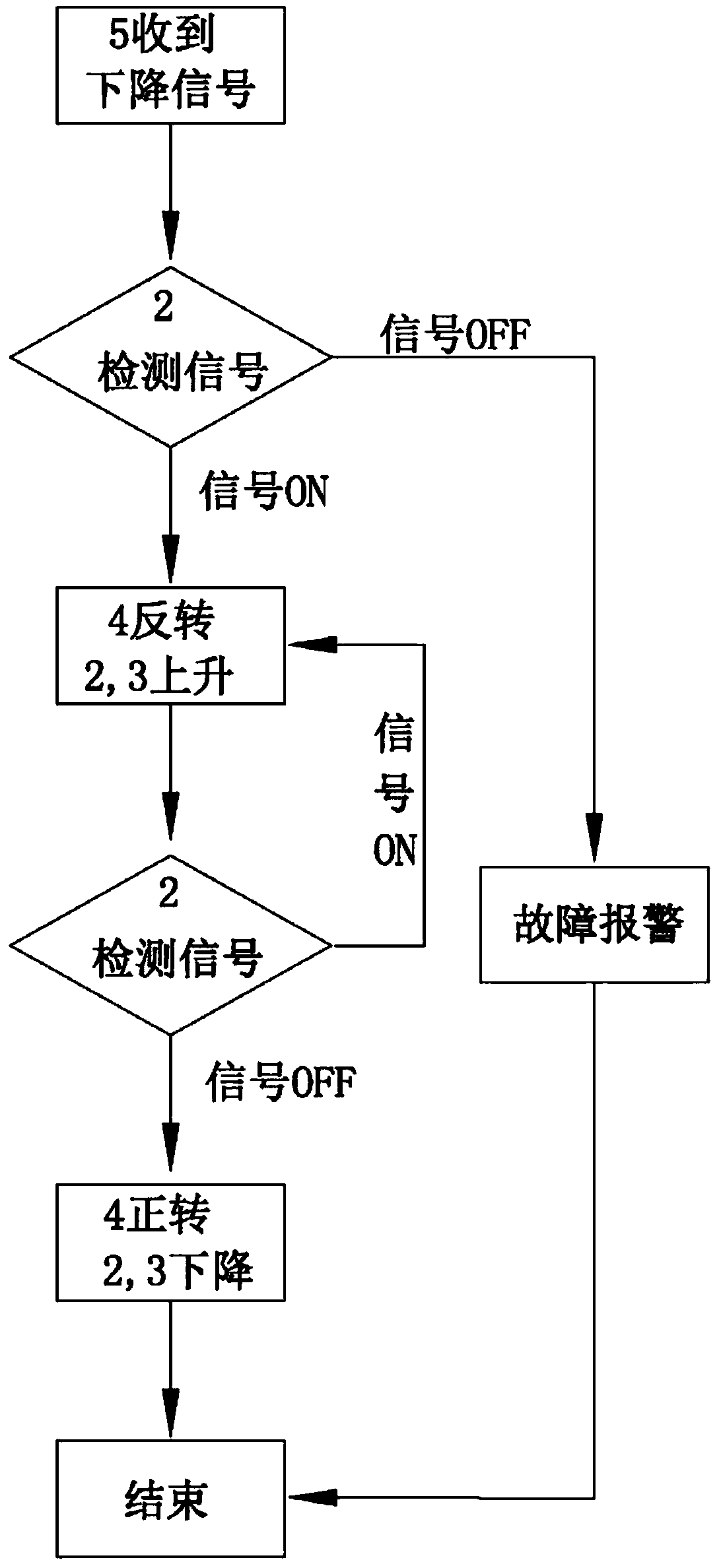

[0068] The difference between the method for controlling the horizontal separation of bathroom laminates described in Embodiment 2 and Embodiment 1 is that:

[0069]The controller 5 is based on the fourth distance value, the fifth distance value, the height difference between the first distance sensor 10 and the second distance sensor 11, and the thickness range of the laminate to calculate the distance between the plane where the second layer of the laminate is located and the barrier 3. distance, and by controlling the forward rotation or reverse rotation of the motor 4, the motor 4 is controlled to stop when the stopper 3 descends or moves down the distance and moves to the position of the second layer of laminates;

[0070] In order to illustrate the specific calculation method, a few specific examples are taken as examples:

[0071] When the first distance sensor and the second distance sensor are arranged on the same horizontal plane, the tolerance of the plate thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com