A kind of caster composite material and preparation method thereof

A composite material and caster technology, which is applied in the field of caster composite material and its preparation, can solve the problems of short life and poor wear resistance of casters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

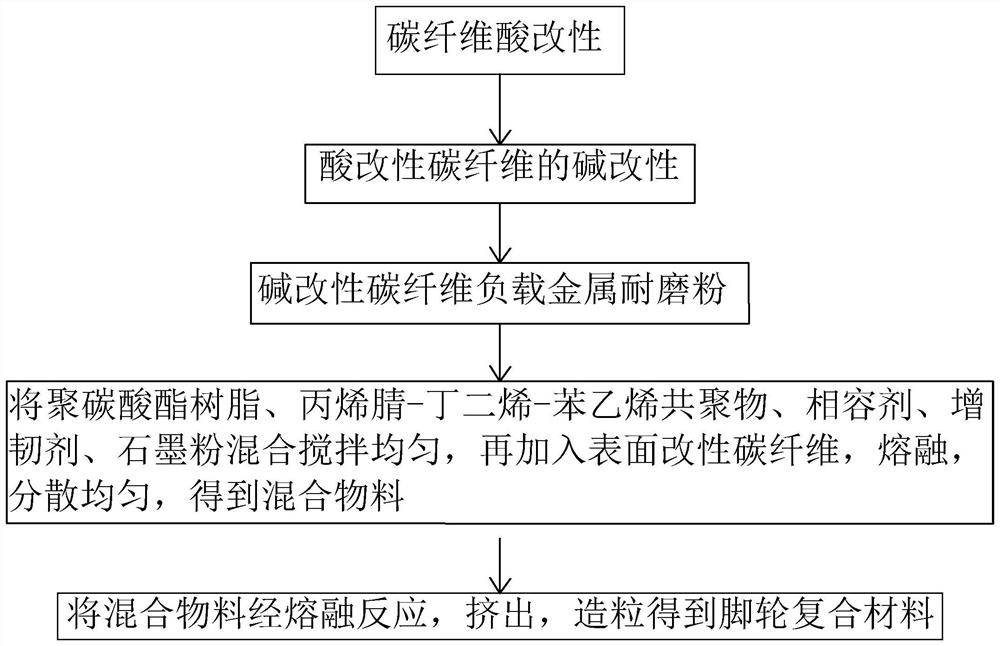

Method used

Image

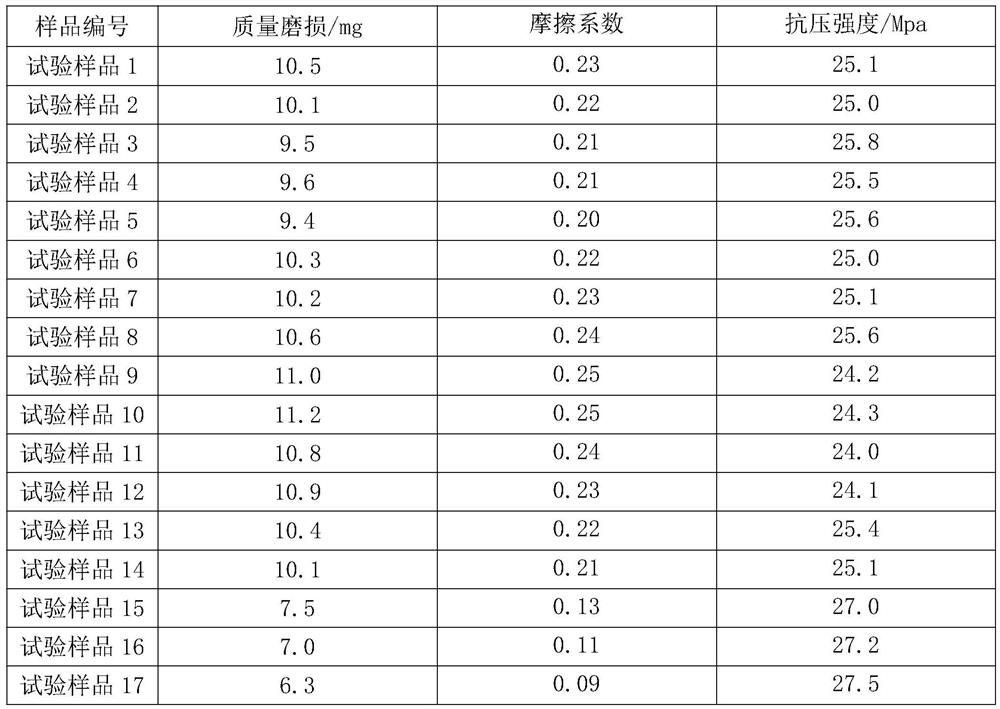

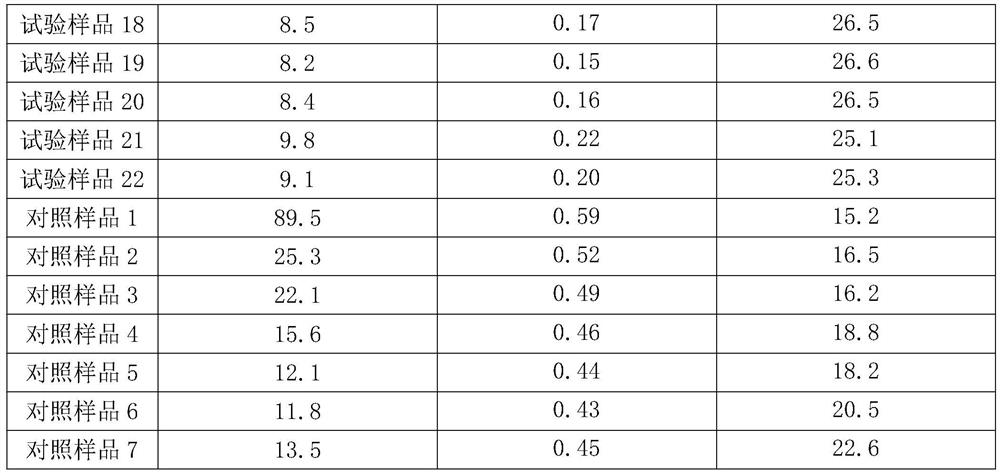

Examples

Embodiment 1

[0047] Embodiment 1: A kind of caster composite material, its raw material comprises the component of following parts by weight:

[0048] 35 parts of polycarbonate resin;

[0049] 25 parts of acrylonitrile-butadiene-styrene copolymer;

[0050] 2 parts of compatibilizer;

[0051] 6 parts of toughening agent;

[0052] 10 parts of graphite powder;

[0053] 3 parts of surface modified carbon fiber;

[0054] The compatibilizer is maleic anhydride grafted ABS, the toughening agent is methyl methacrylate, and the metal wear-resistant powder is nano molybdenum disulfide.

[0055] The preparation steps of surface modified carbon fiber are as follows:

[0056] (1) Acid modification of carbon fiber: After cleaning and drying the carbon fiber, stir and impregnate it with 1mol / L hydrochloric acid solution for 1 hour, filter it with suction, then wash it with deionized water, and obtain acid-modified carbon fiber after drying;

[0057] (2) Alkali modification of the acid-modified carb...

Embodiment 2

[0063] Embodiment 2: A caster composite material, the difference from Embodiment 1 is that its raw materials include the following components in parts by weight:

[0064] 45 parts of polycarbonate resin;

[0065] 15 parts of acrylonitrile-butadiene-styrene copolymer;

[0066] 3 parts of compatibilizer;

[0067] 8 parts of toughening agent;

[0068] 14 parts of graphite powder;

[0069] Surface modified carbon fiber 4 parts.

Embodiment 3

[0070] Embodiment 3: A kind of caster composite material, differs from embodiment 1 in that its raw material includes the following components in parts by weight:

[0071] 40 parts of polycarbonate resin;

[0072] 20 parts of acrylonitrile-butadiene-styrene copolymer;

[0073] 4 parts of compatibilizer;

[0074] 10 parts of toughening agent;

[0075] 20 parts of graphite powder;

[0076] 5 parts of surface modified carbon fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com