Case sewing processing equipment corresponding to shoulder strap positioning configuration

A technology for processing equipment and bags, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve problems such as uneven shoulder straps, poor comfort in use, and poor pass rate of finished products, so as to achieve perfect appearance and avoid unevenness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

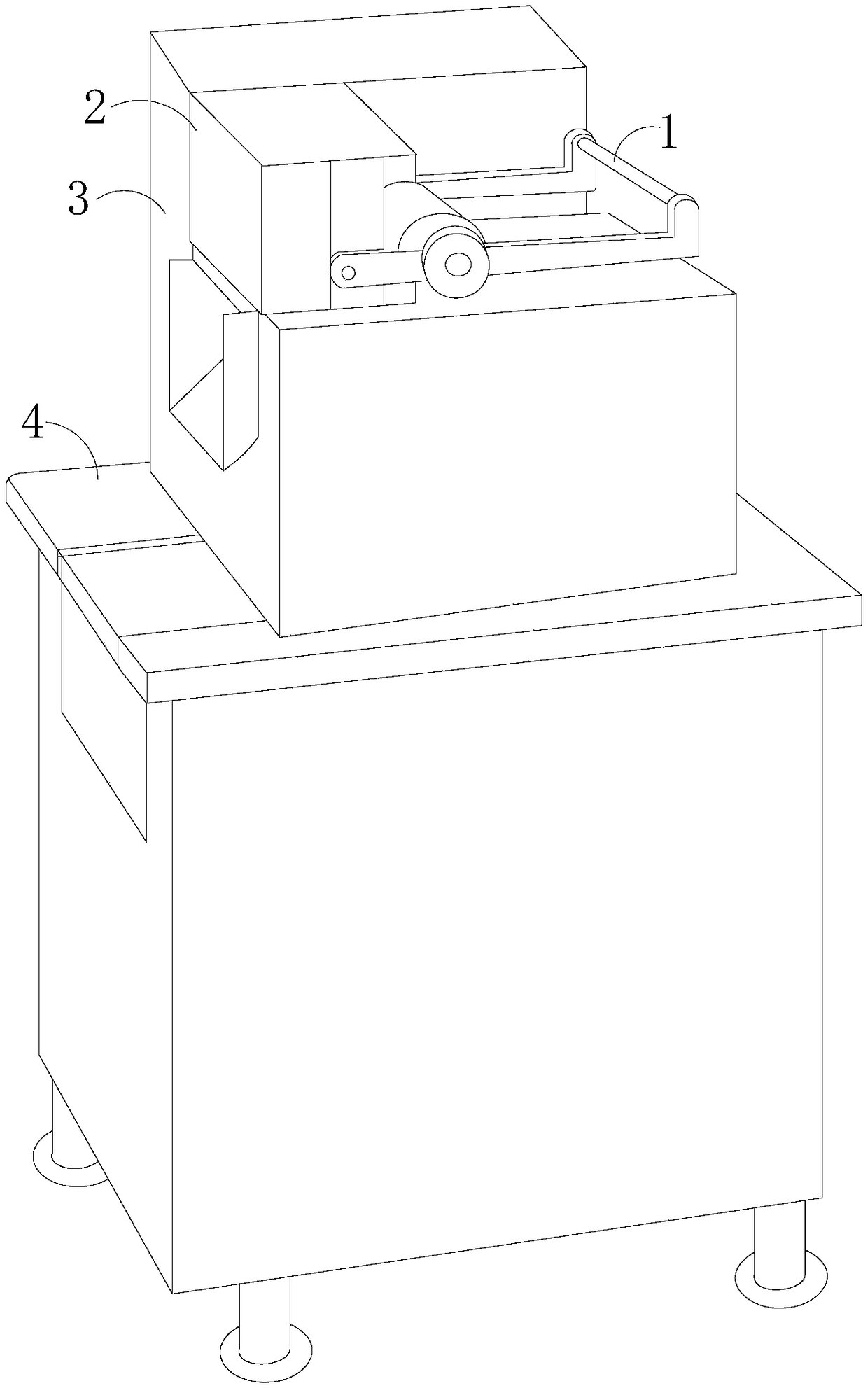

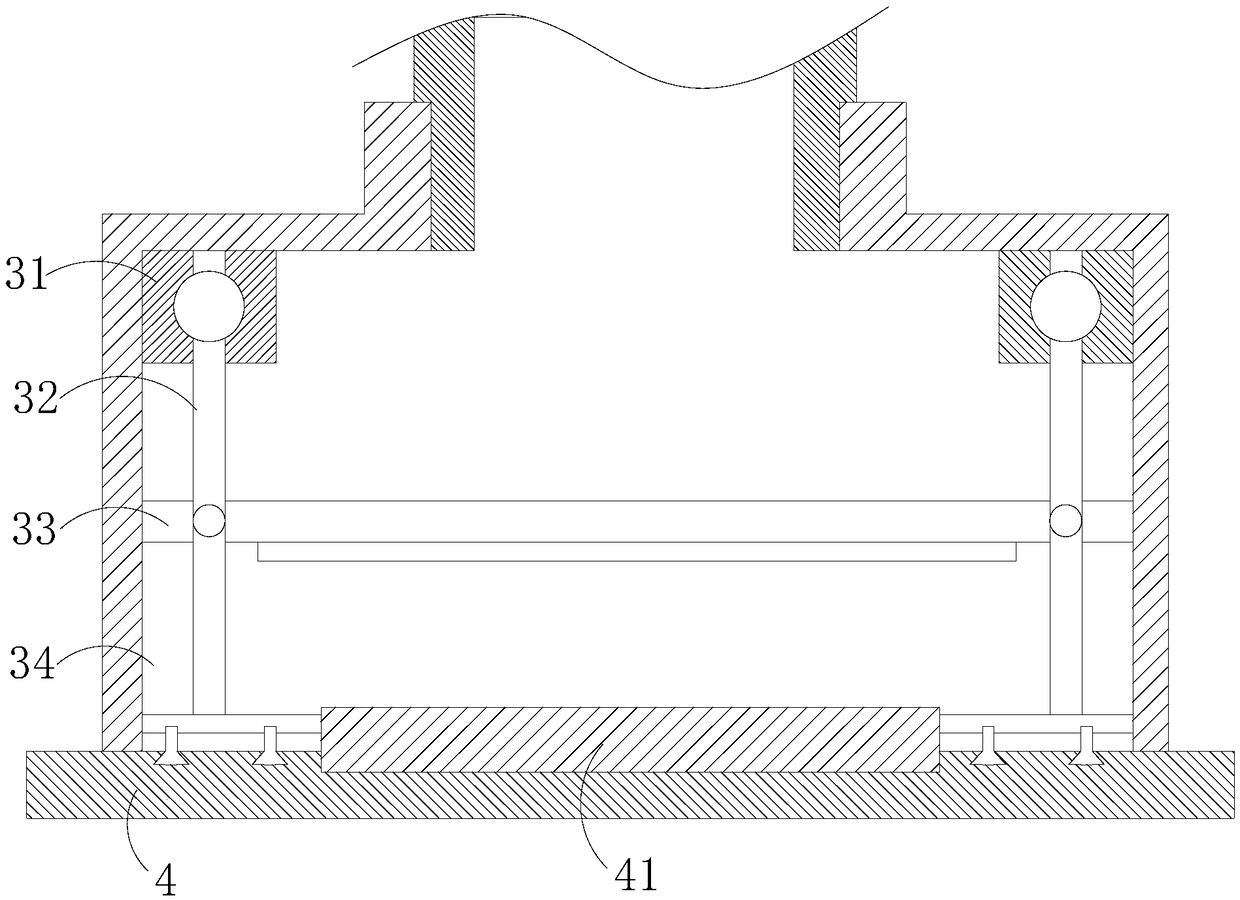

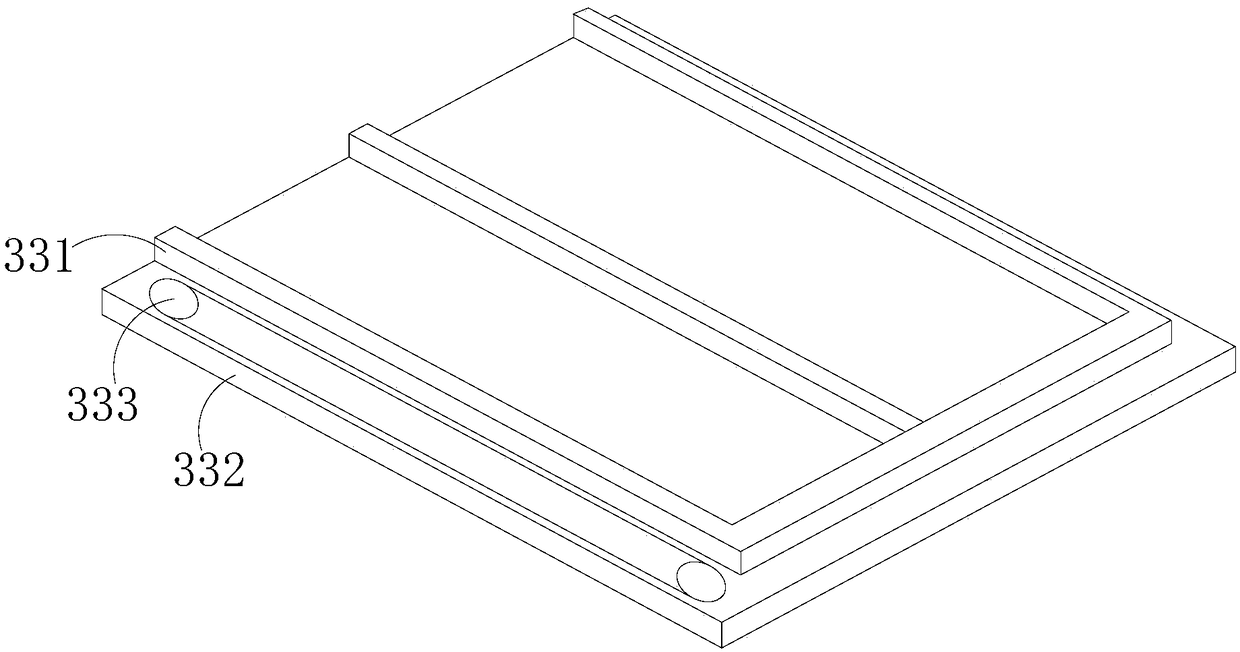

[0027] like Figure 1-Figure 7 As shown, the present invention provides a case and bag sewing processing equipment corresponding to the positioning configuration of the shoulder belt, and its structure includes a line guide roller 1, a guide roller seat 2, a sewing center 3, and a cabinet 4. The guide roller seat 2, the sewing center 3 1. The chassis 4 is installed vertically from top to bottom to form a sewing drive system. The wire-entry guide roller 1 is installed outside the upper end of the sewing center 3 and its internal signal terminals are electrically connected. The wire-entry guide roller 1 is fixed by the guide roller seat 2. The sewing center 3 includes a driver 31, a guide rail 32, a positioning platen 33, and a suture cavity 34. The positioning platen 33 is installed horizontally between the two guide rails 32, and is electrically connected to the driver 31 installed on the upper end of the guide rail 32. Connection, the suture chamber 34 is docked with the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com