Roll paper cutting device

A technology of cutting and rolling paper, applied in the directions of transportation and packaging, sending objects, processing of thin materials, etc., can solve the problems of uneven paper head, difference in length of vapor-phase anti-rust paper, different disk weight, etc., so as to avoid uneven paper head, High cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings.

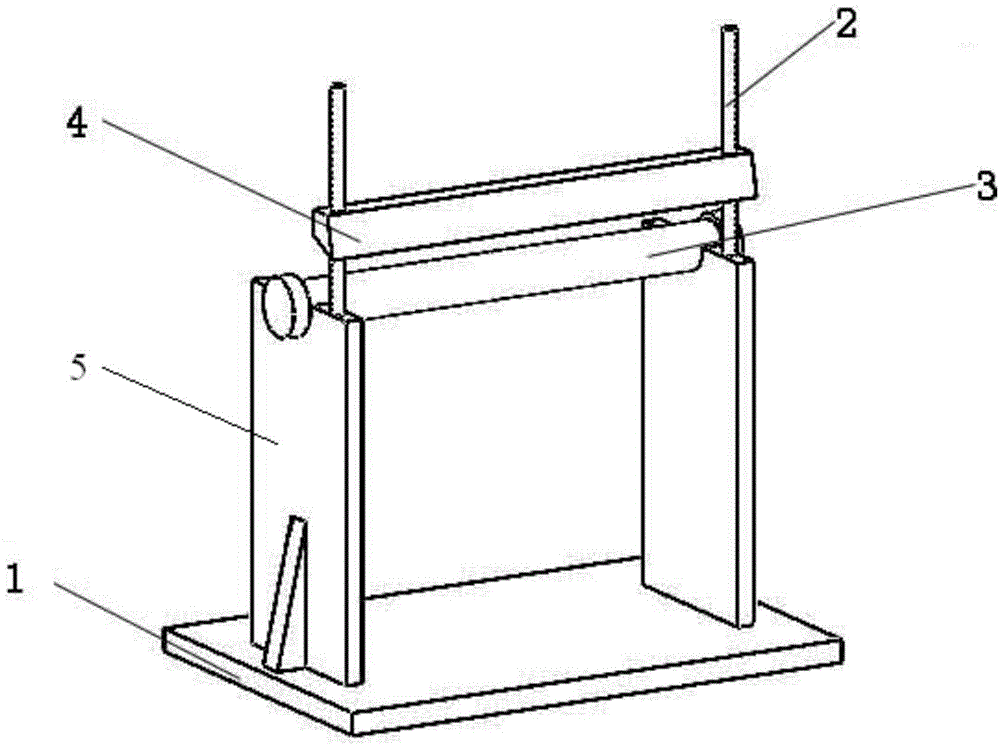

[0009] Such as figure 1 As shown: the roll paper cutting device includes a base 1, a support rod 2, a central pivot pin 3, a cutting block 4, a bracket 5, and the like.

[0010] Such as figure 1 As shown, the present invention includes a base 1, a support 5 is provided at both ends of the base 1, and a central shaft pin 3 is erected on the top of the support 5, and the central shaft pin 3 is used to pass through the hollow hole of the air-phase antirust paper roll; The upper part of the side bracket 5 is provided with supporting rods 2 respectively, and cutting blocks 4 are arranged on the supporting rods 2 on both sides, and the two ends of the cutting blocks 4 are provided with jacks matched with the supporting rods 2, and the cutting blocks 4 pass through the jacks. Insert it on the support pole 2.

[0011] The outer lower edge of the cutting block 4 is a cutting edge. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com