Reservoir dredging method

A reservoir and silting technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as time-consuming, scrapped reservoirs, and poor stability, and achieve the effect of saving a lot of dredging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] A method for dredging a reservoir, comprising the steps of:

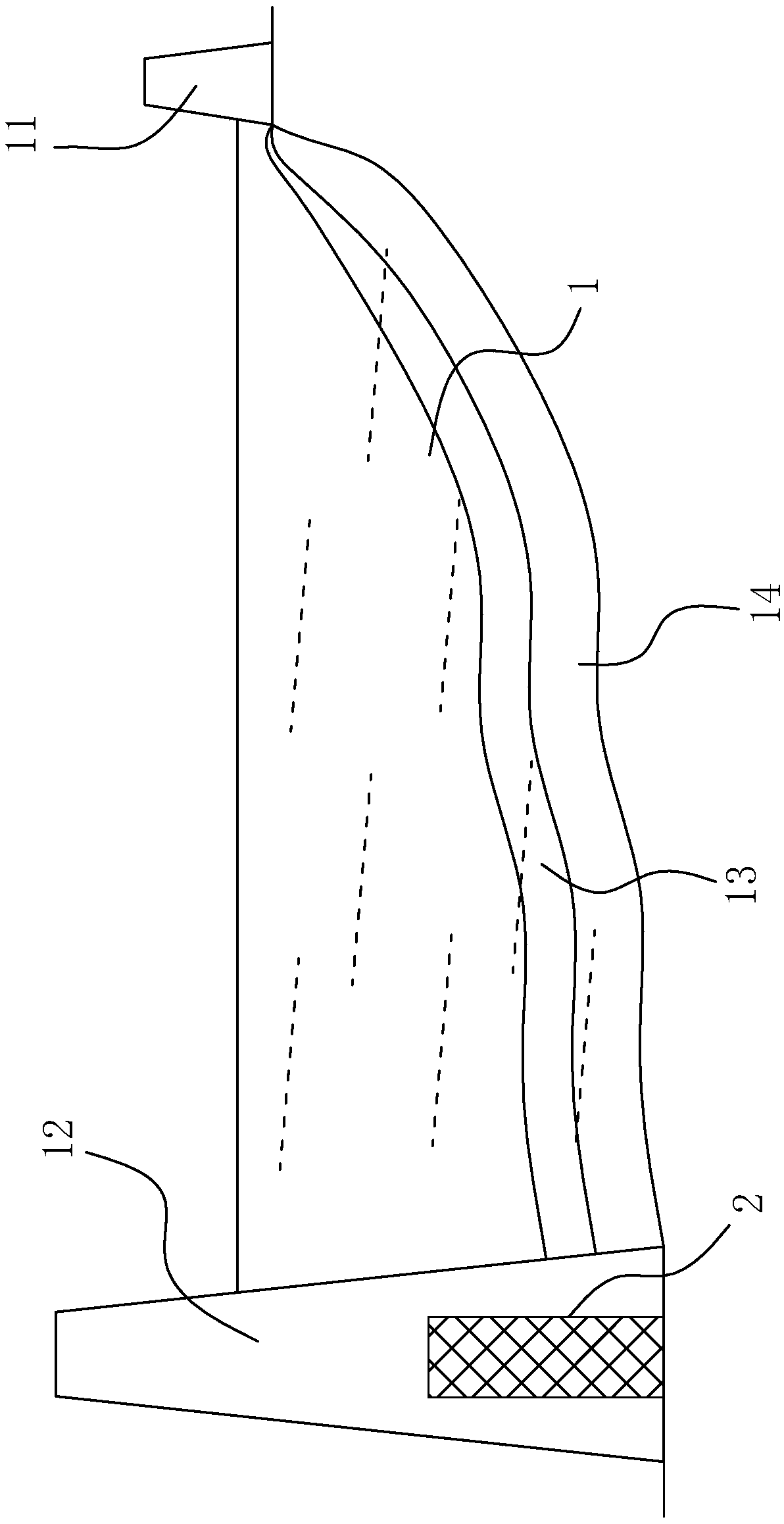

[0043] Step 1: close the water inlet gate 11 of the reservoir 1, and open the water outlet gate 12 of the reservoir 1 at the same time;

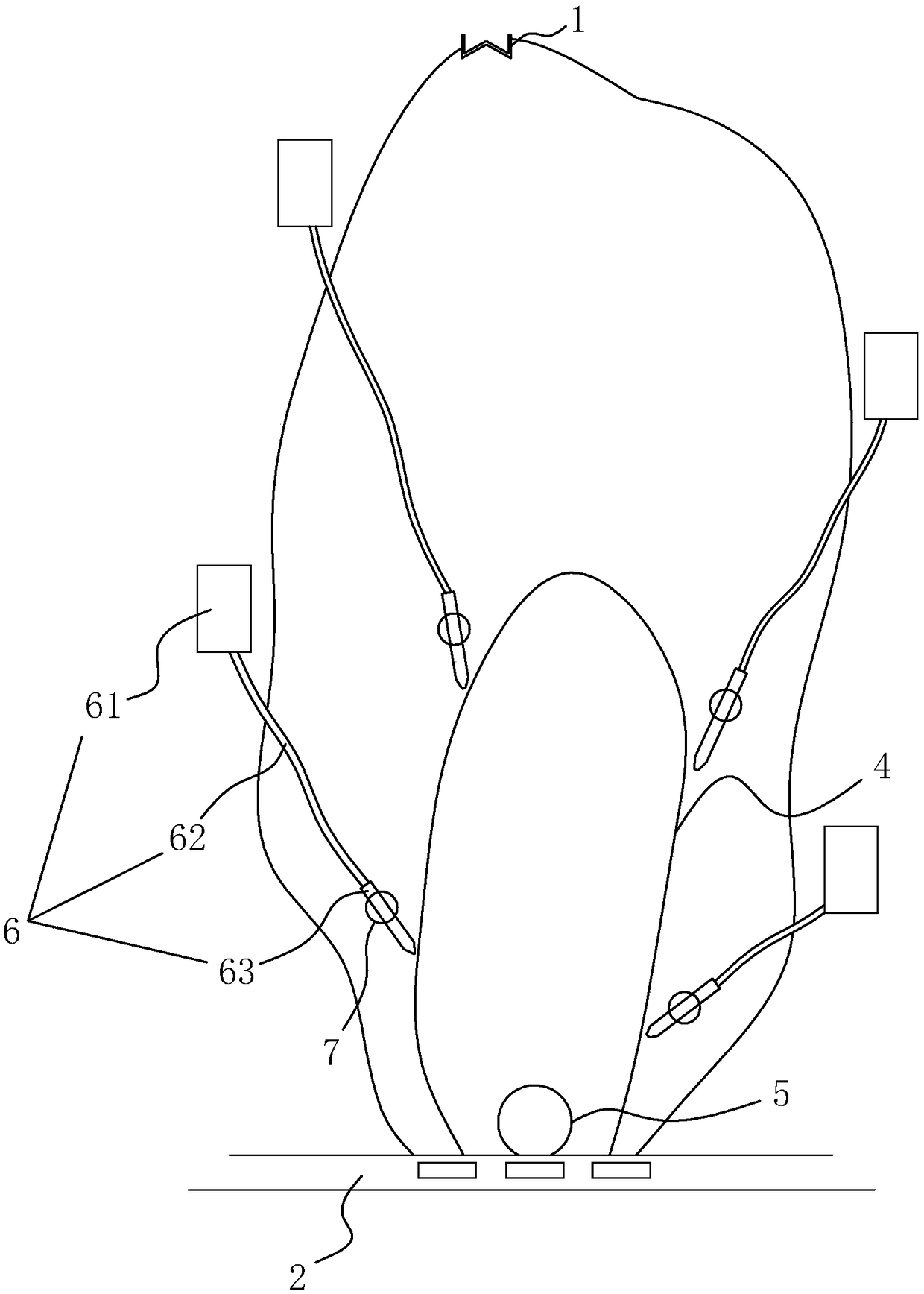

[0044] Step 2: using the clean water mud flushing device 6 to flush the mud to the outlet gate 12 of the reservoir 1, so that part of the upper layer of mud 13 can be flushed out of the reservoir 1;

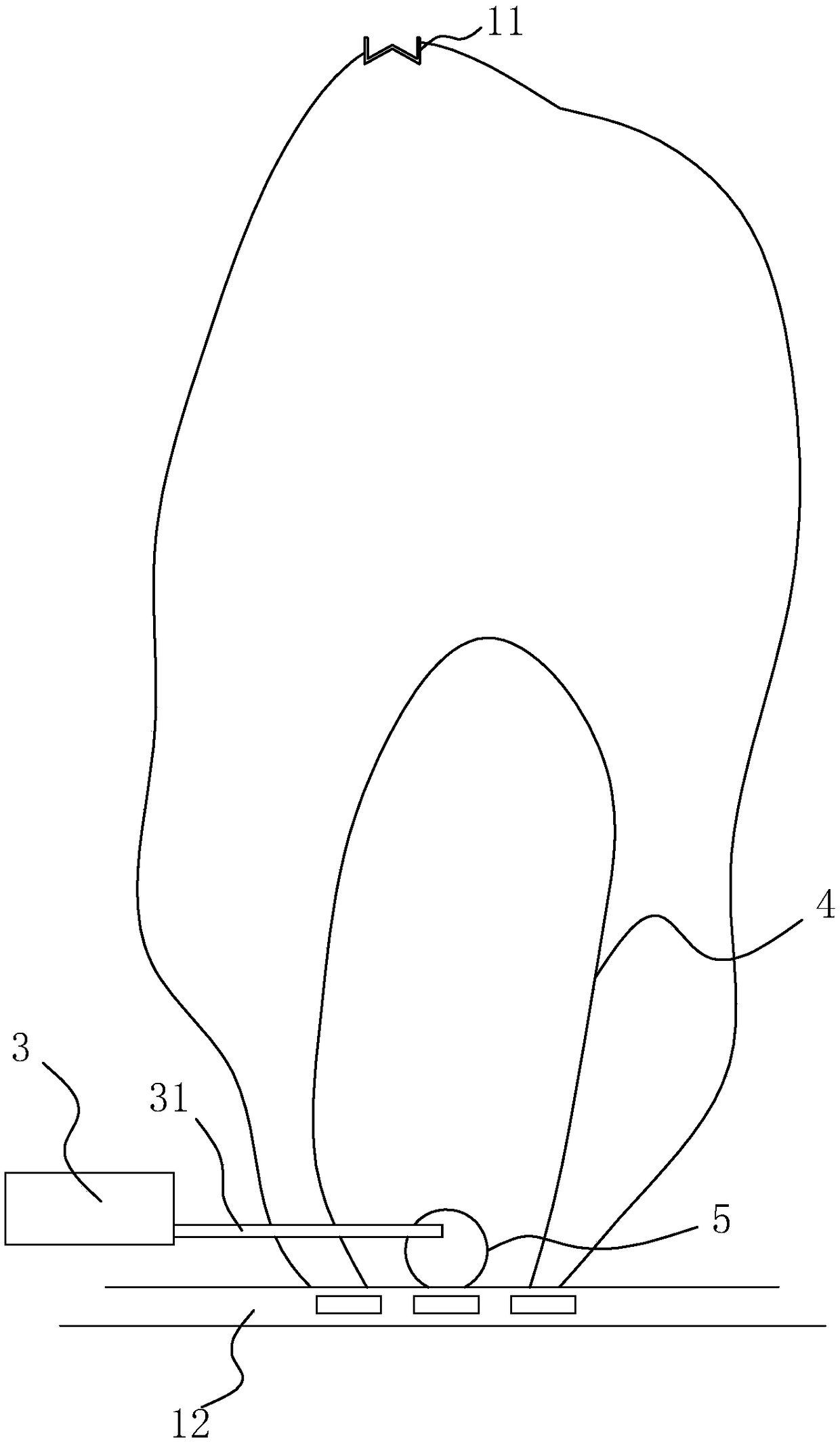

[0045] Step 3: dig out the silt pit 5 at the bottom of the reservoir 1, and extend the siphon pipe 31 of the siphon device 3 into the bottom of the silt pit 5;

[0046] Step 4: Utilize a bulldozer to push the upper layer of silt 13 into the silt pit 5, and then use the siphon device 3 to extract the upper layer of silt 13 accumulated in the silt pit 5;

[0047] Step 5: using an excavator to dig out the lower layer of sludge 14 and transport the excavated lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com