Dredging loader for water sump

A technology of loaders and water tanks, applied in drainage, safety devices, earth movers/shovels, etc., can solve the problems of high labor intensity and low dredging efficiency, and achieve increased dredging times, good economic benefits, The effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

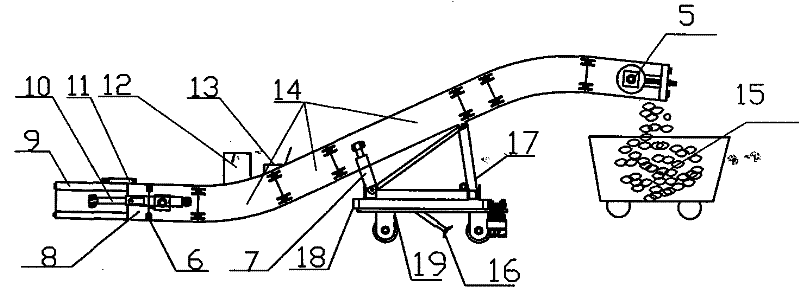

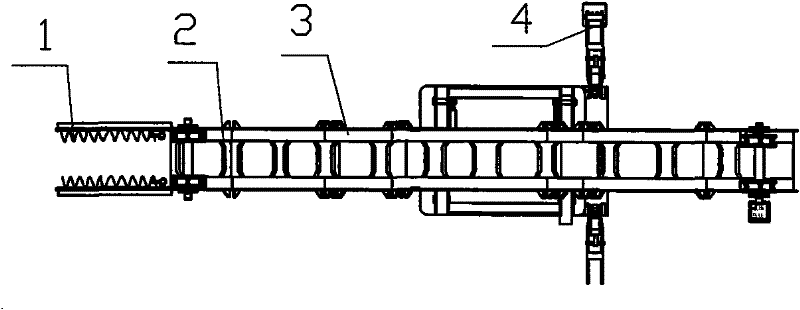

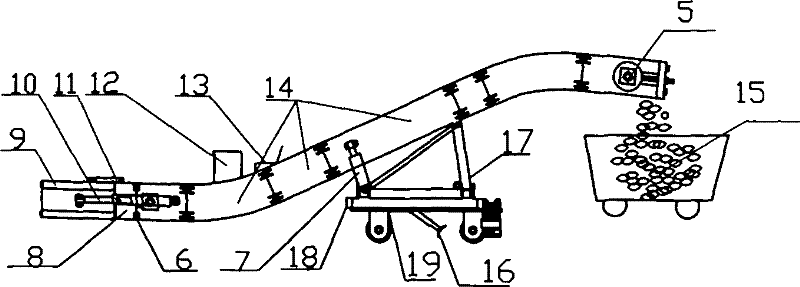

[0019] Depend on figure 1 , figure 2 It can be seen that the water tank dredging loader is mainly composed of a scraper conveyor 5, a cleaning guard 9 connected to the tail of the scraper conveyor 5, a walking trolley 19 for loading the scraper conveyor 5, and a device for operating various operating mechanisms. The operation console 12, the motor and the hydraulic pump are composed of two cleaning guards respectively connected to both sides of the tail of the scraper conveyor 5, and each cleaning guard consists of a semi-cylindrical protective plate installed on the inner side of the protective plate The spiral impeller 1 is composed of cleaning rubber fixed under the protective plate. The protective plate is connected to the front end of the connecting plate 8 through the vertical horizontal pin shaft, and the connecting plate 8 is connected to the tail of the scraper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com