Method for monitoring deformation amount of deep soft rock roadway

A technology of deformation amount and roadway, applied in the field of mine safety, can solve problems such as difficult to grasp the creep time law of soft rock roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

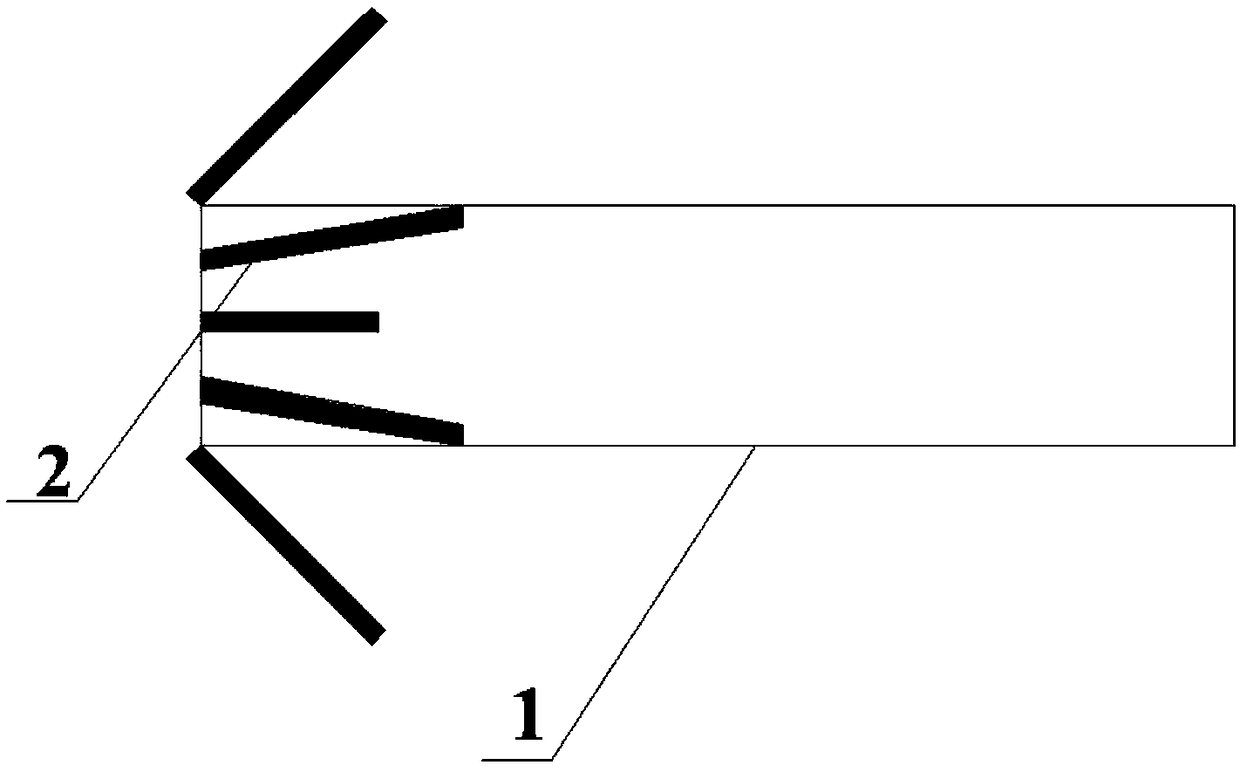

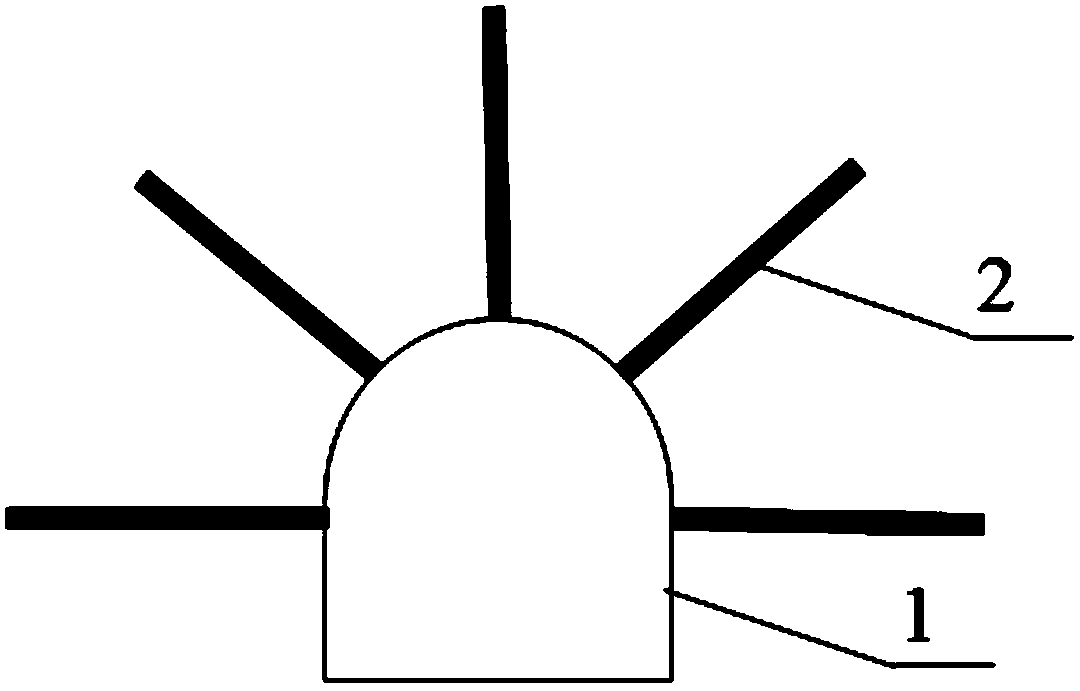

[0025] Drilling: At the head of the roadway (1) excavation, when the slag discharge is completed after the excavation and blasting, the monitoring point is selected, and 5 boreholes (2) are constructed on the roof and both sides. The distribution of the boreholes is as follows: figure 1 and 2 As shown, there are 3 boreholes (2) on the top plate, and 1 borehole (2) is arranged on each side of the side. The angle between the borehole (2) and the roadway (1) is 45 degrees. ) with a depth of 5m (can also be selected according to surrounding rock conditions or loose circles), and the diameter of the borehole (2) is 90mm.

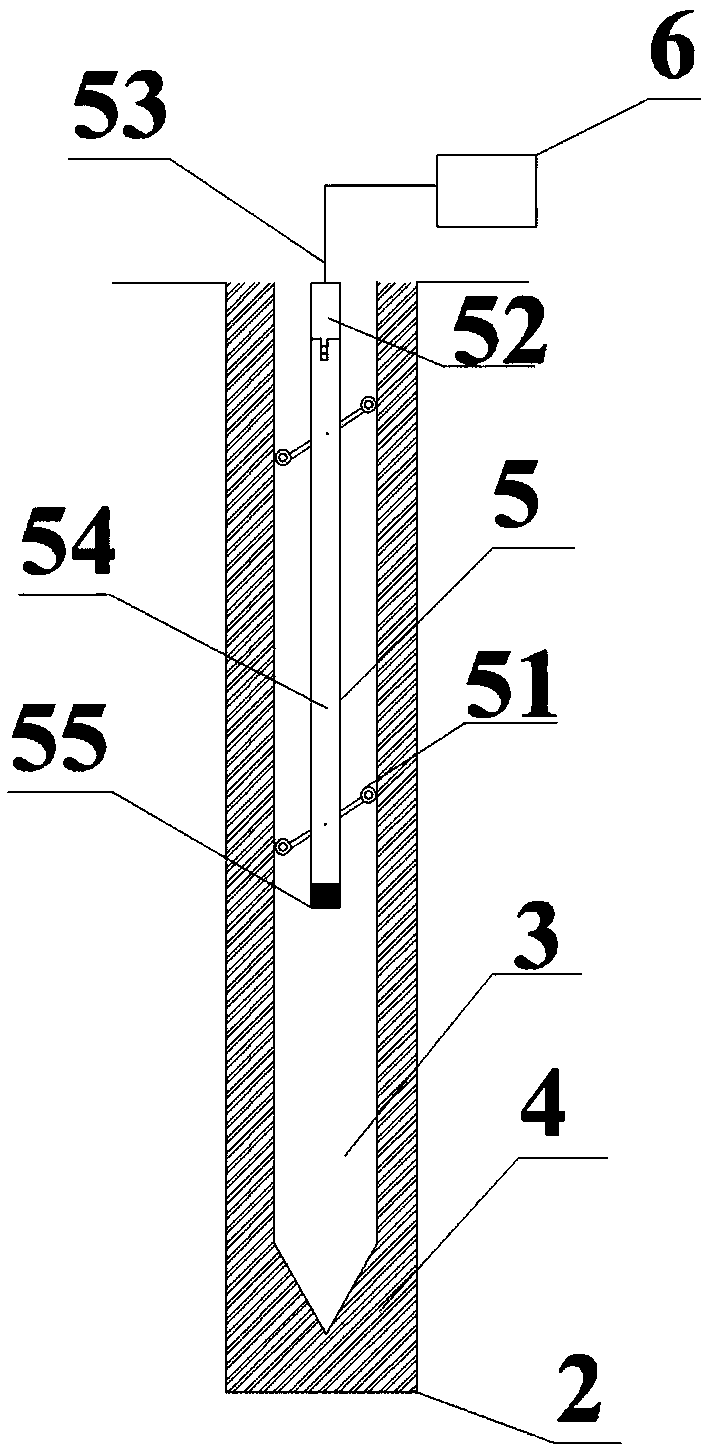

[0026] Install the inclinometer tube: install the inclinometer tube (3) in the borehole, such as image 3 As shown, the bottom of the inclinometer tube (3) is conical. When installing, the two symmetrical notches of the inclinometer tube (3) should be placed vertically on the surface of the roadway (1). (3) and the surrounding rock wall of the borehole (2) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com