Plastic laser front case penetrating welding vehicle-mounted camera

A penetrating camera technology, which is applied in the field of vehicle cameras, can solve problems such as temperature rise, image stability, and slow sensor heat dissipation, and achieve good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

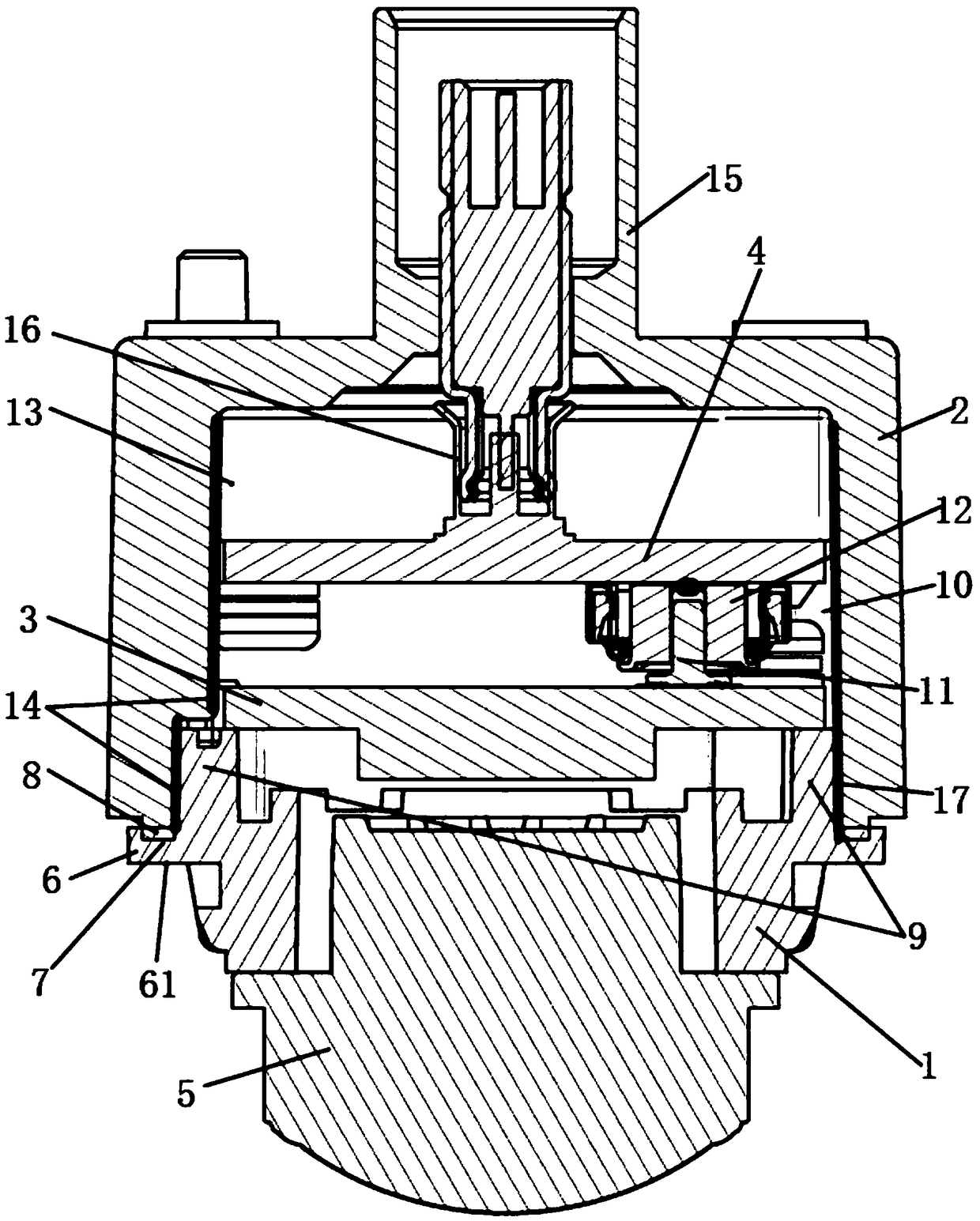

[0017] A vehicle-mounted camera with penetration welding of plastic laser front shell, see figure 1 : It includes a front case 1, a rear case 2, a first substrate 3, and a second substrate 4, the front case 1 and the rear case 2 are made of plastic, the front end of the front case 1 is fixed with a front convex lens 5, and the front end of the front case 1 The inner groove 7 is arranged on the outer periphery of the rear end face of the side convex end 6 for positioning the rear shell 2, and the front end face 61 corresponding to the inner groove 7 of the side convex end 6 is a plane, and the rear shell 2 faces toward the inner groove 7. Part of it is a raised positioning 8, the first substrate 3 is fixed on the rear substrate mounting part 9 of the front shell 1, the second substrate 4 is fixed on the corresponding substrate mounting part 10 of the rear shell 2, and the first substrate 3 of the first substrate 3 A rear end connector 11 is connected to the front slot 12 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com