Thermostat rotating table shaft system seal design

A temperature box and turntable technology, applied in the direction of engine seals, mechanical equipment, instruments, etc., can solve the problems of short circuit of conductive slip rings, entry of dust and water vapor, bearing corrosion, etc., to prevent dust and water vapor from entering the inside of the bearing and avoid condensation. The effect of producing water and improving the accuracy of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

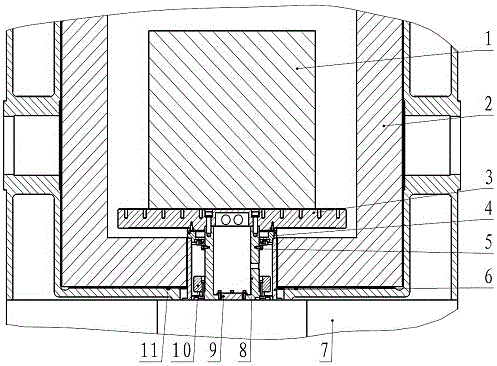

[0018] like figure 1 As shown, this embodiment is used in the shaft seal design of the incubator turntable, including: test equipment 1, incubator 2, working table 3, upper sealing plate 4, lower sealing plate 5, sealing bracket 6, frame 7, main shaft 8, Conductive slip ring 9, heating plate 10 and sealing ring 11.

[0019] like figure 1 As shown, the workbench 3 is fixed on the spindle 8 for installing the test equipment 1 and rotates together with the shaft system. An upper sealing plate 4 and a lower sealing plate 5 are installed between the main shaft 8 and the sealing bracket 7, a labyrinth sealing structure is formed between the two sealing plates, and the lower sealing plate 5 is filled with sealing grease to complete the rotary sealing function.

[0020] 2. The conductive slip ring 9 is fixed on the lower end face of the inner flange of the main shaft 8, and is used to transmit the signal of the test equipment 1 to the measurement and control system, and collect s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com