High-resilience shoe insole

A high-resilience, shoe technology, applied in soles, footwear, applications, etc., can solve the problems of troublesome production, affecting the comfort of shoes, low resilience and softness, etc., to improve strength, improve wearing comfort, rebound Good elasticity and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

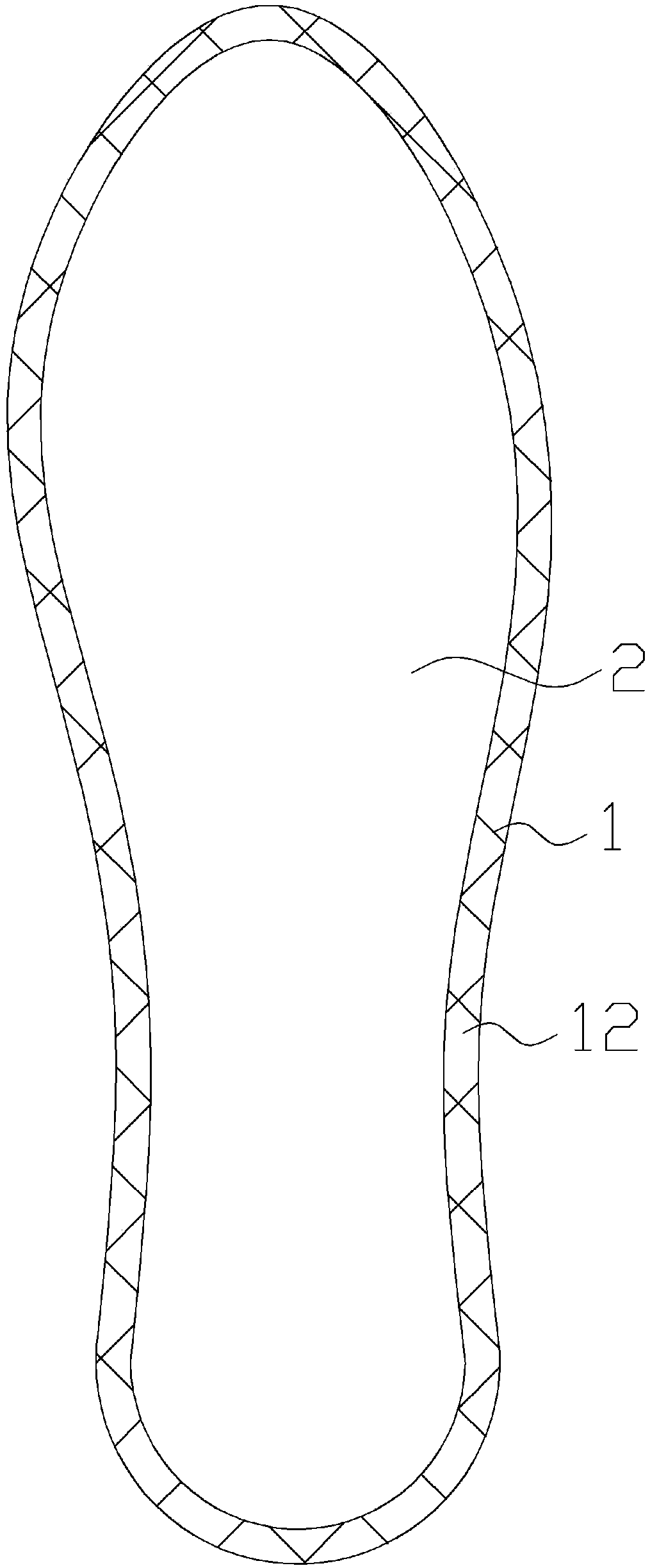

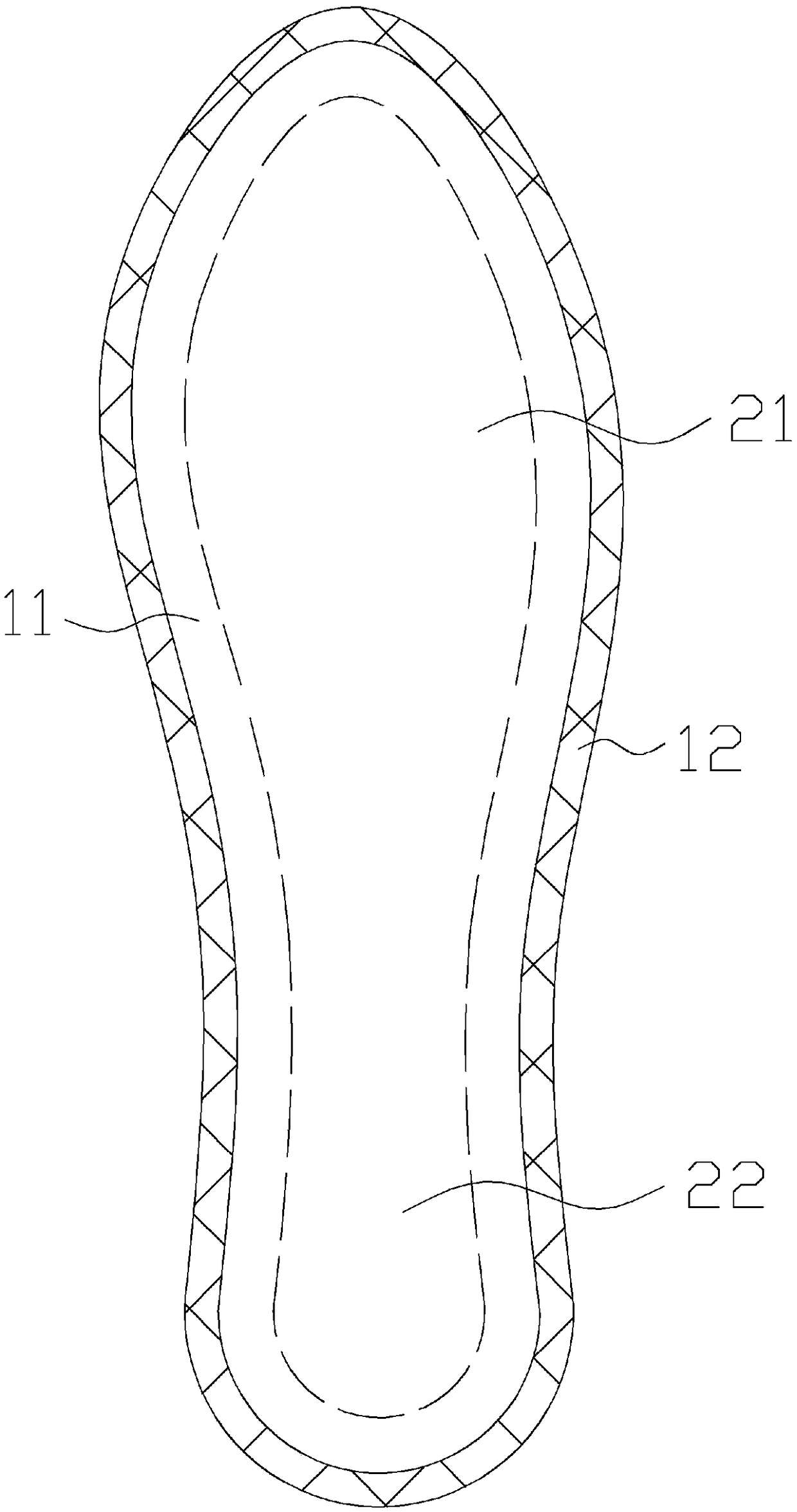

[0022] refer to figure 1 , figure 2 , image 3 with Figure 4 , a high-resilience shoe midsole of the present invention includes a cloth body 1 and a PU body 2, and the PU body 2 can be obtained by solidifying commercially available PU materials through conventional processing techniques.

[0023] The cloth body 1 is divided into a stitching portion 11 and a connecting portion 12, the stitching portion 11 and the connecting portion 12 are integrally formed, and the width of the stitching portion 11 is between 5mm and 7mm. In this embodiment, the width of the stitching portion 11 is preferably 5mm, and the stitching portion 11 is used for sewing with the vamp.

[0024] The middle part of the connection part 12 is provided with a through hole 121. During the production process of the PU body 2, the PU material can be placed on the connection part 12 to penetrate the connection part 12 and cover the entire through hole 121, so that the PU material is solidified. Finally, a p...

Embodiment 2

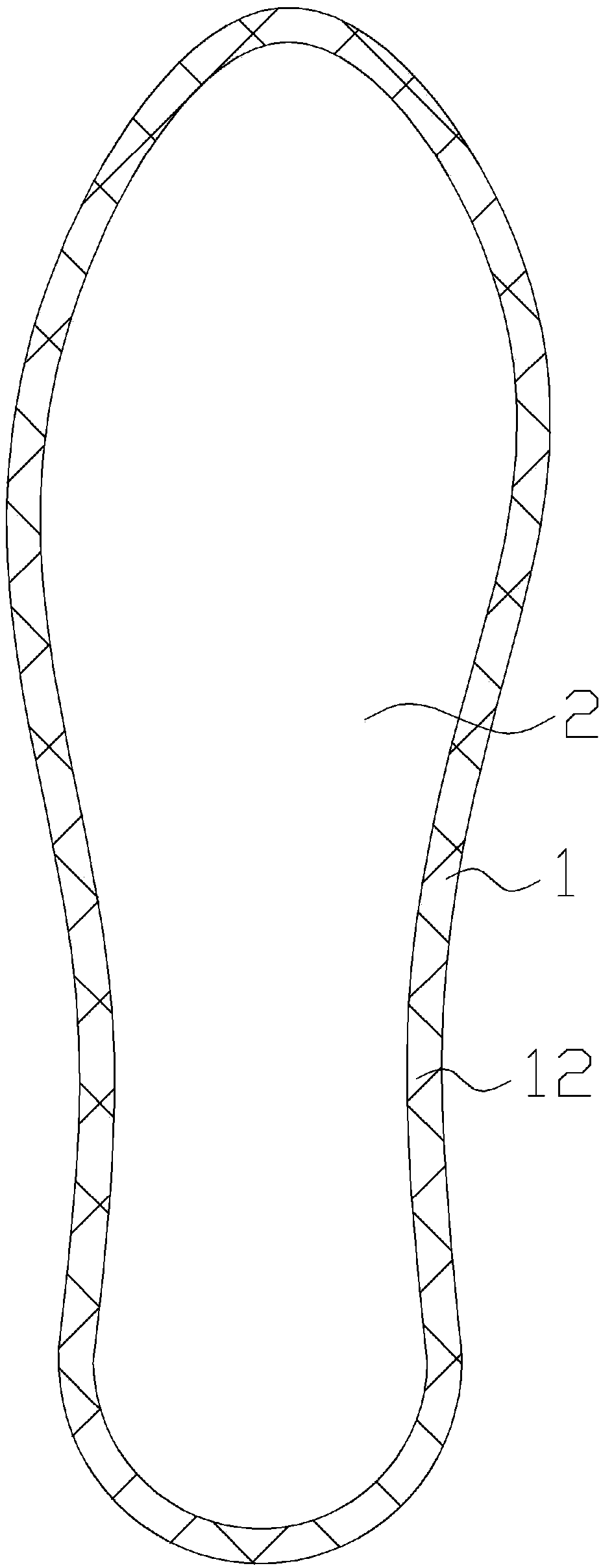

[0028] refer to figure 1 , figure 2 , Figure 5 with Image 6 , a high-resilience shoe midsole of the present invention includes a cloth body 1 and a PU body 2, and the PU body 2 can be obtained by solidifying commercially available PU materials through conventional processing techniques.

[0029] The cloth body 1 is divided into a seamed portion 11 and a connecting portion 12, the seamed portion 11 and the connecting portion 12 are integrally formed, and the width of the seamed portion 11 is between 5 mm and 7 mm. In this embodiment, the width of the seamed portion 11 is preferably 7 mm. 11 is used for sewing with the vamp.

[0030] The middle part of the connection part 12 is provided with a through hole 121, and the connection part 12 is provided with a plurality of reinforcement strips 122, and the reinforcement strips 122 span the through holes 121, and the PU body 2 can place its PU material in the connection part during the manufacturing process. 12, to permeate th...

Embodiment 3

[0035] refer to figure 1 , figure 2 , Figure 5 with Image 6 , a high-resilience shoe midsole of the present invention includes a cloth body 1 and a PU body 2, and the PU body 2 can be obtained by solidifying commercially available PU materials through conventional processing techniques.

[0036] The cloth body 1 is divided into a stitching portion 11 and a connecting portion 12, the stitching portion 11 and the connecting portion 12 are integrally formed, and the width of the stitching portion 11 is between 5 mm and 7 mm. In this embodiment, the width of the stitching portion 11 is preferably 6 mm. 11 is used for sewing with the vamp.

[0037] The middle part of the connection part 12 is provided with a through hole 121, and the connection part 12 is provided with a plurality of reinforcement strips 122, and the reinforcement strips 122 span the through holes 121, and the PU body 2 can place its PU material in the connection part during the manufacturing process. 12, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com