Prickly ash screening equipment

A cleaning equipment and cleaning technology, which are used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., to achieve the effects of saving labor intensity, improving screening efficiency and screening accuracy, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

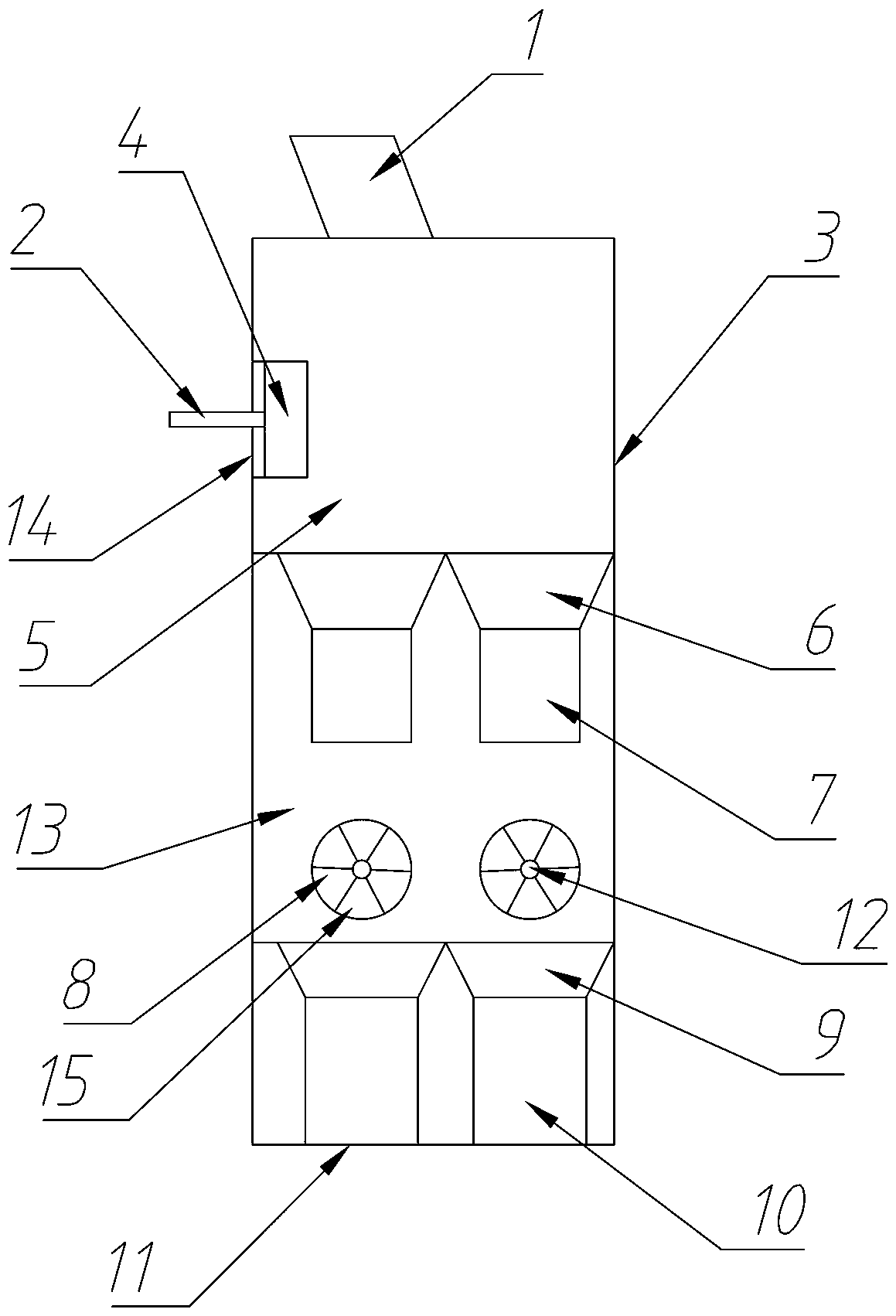

[0026] The prickly ash cleaning equipment of the present invention includes a cleaning casing 3, a cleaning inlet 1 and a plurality of cleaning outlets 11 arranged on the cleaning casing 3; the cleaning inlet 1 is arranged on the cleaning casing The cleaning device in 3 is connected to the cleaning outlet 11;

[0027] The cleaning device includes a primary cleaning device and a secondary cleaning device, the primary cleaning device and the secondary cleaning device are arranged along the vertical direction of the cleaning housing 3, and the primary cleaning device is arranged on the There are two primary cleaning and material channels, each of the primary cleaning and material channels is connected with a secondary cleaning device, and each secondary cleaning device is provided with a secondary cleaning material channel. The secondary cleaning material channels are respectively connected with the cleaning outlet 11;

[0028] The primary cleaning device and the secondary clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com