Soil rehabilitation and quality improvement equipment

A quality improvement equipment and soil remediation technology, applied in the restoration of contaminated soil, etc., can solve the problems of poor leaching effect and low leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

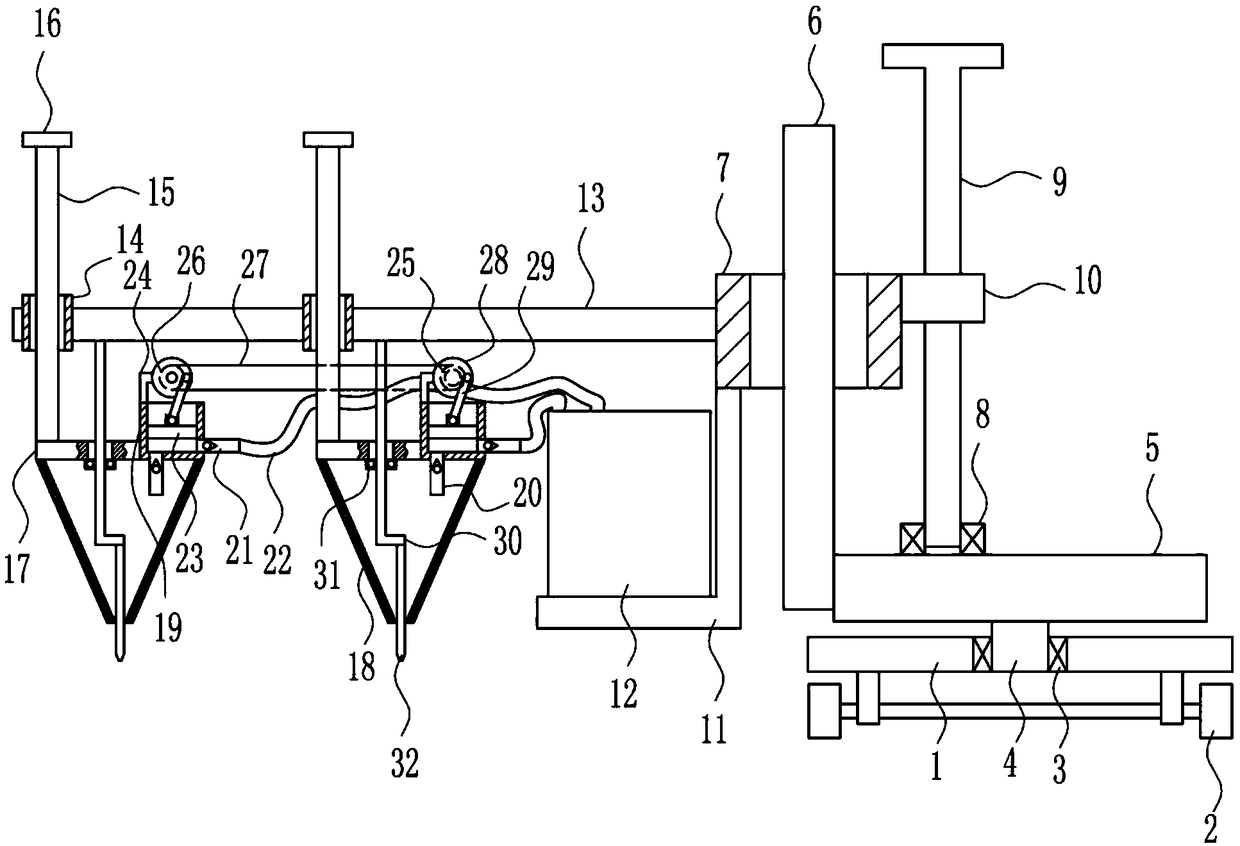

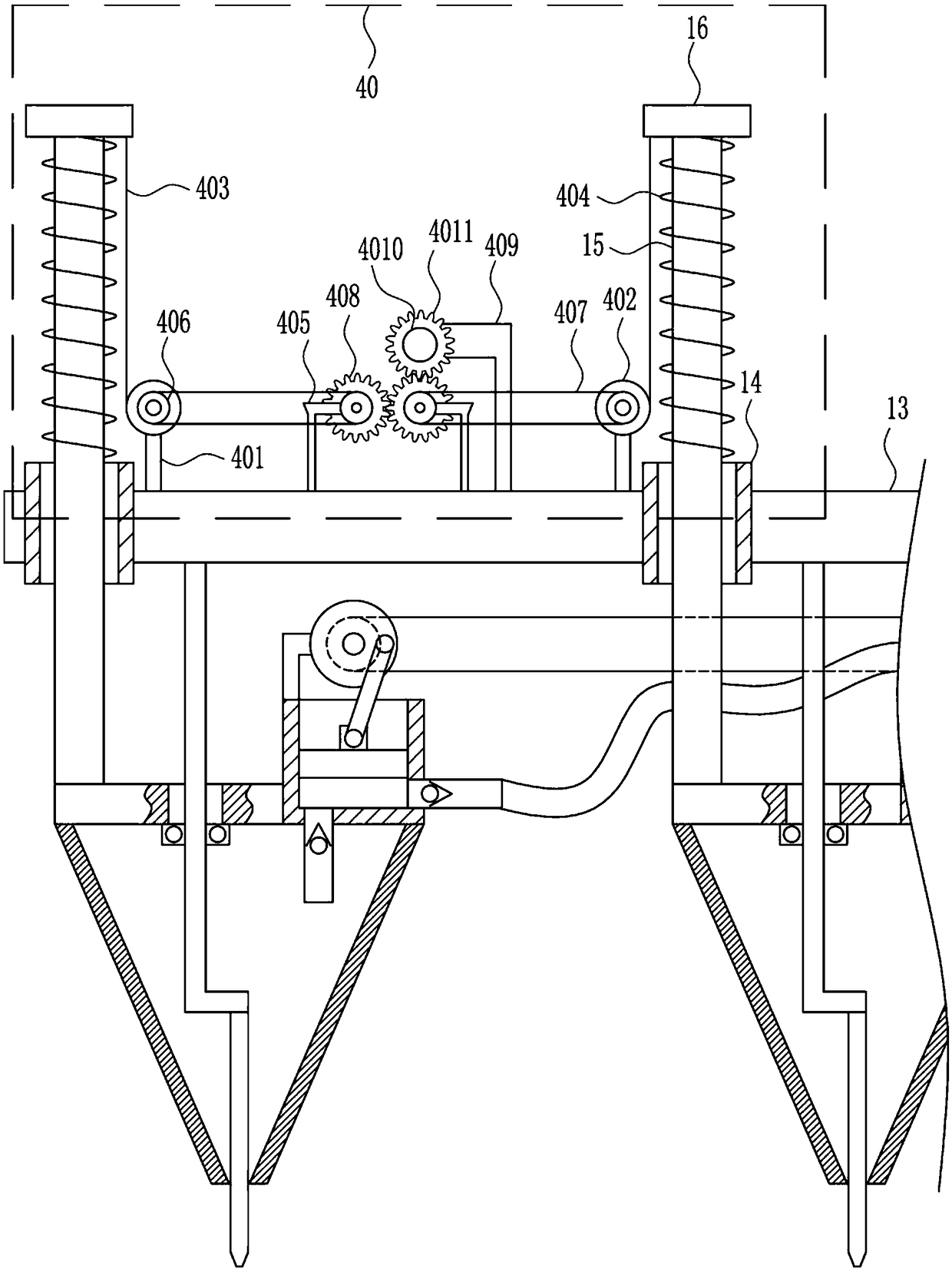

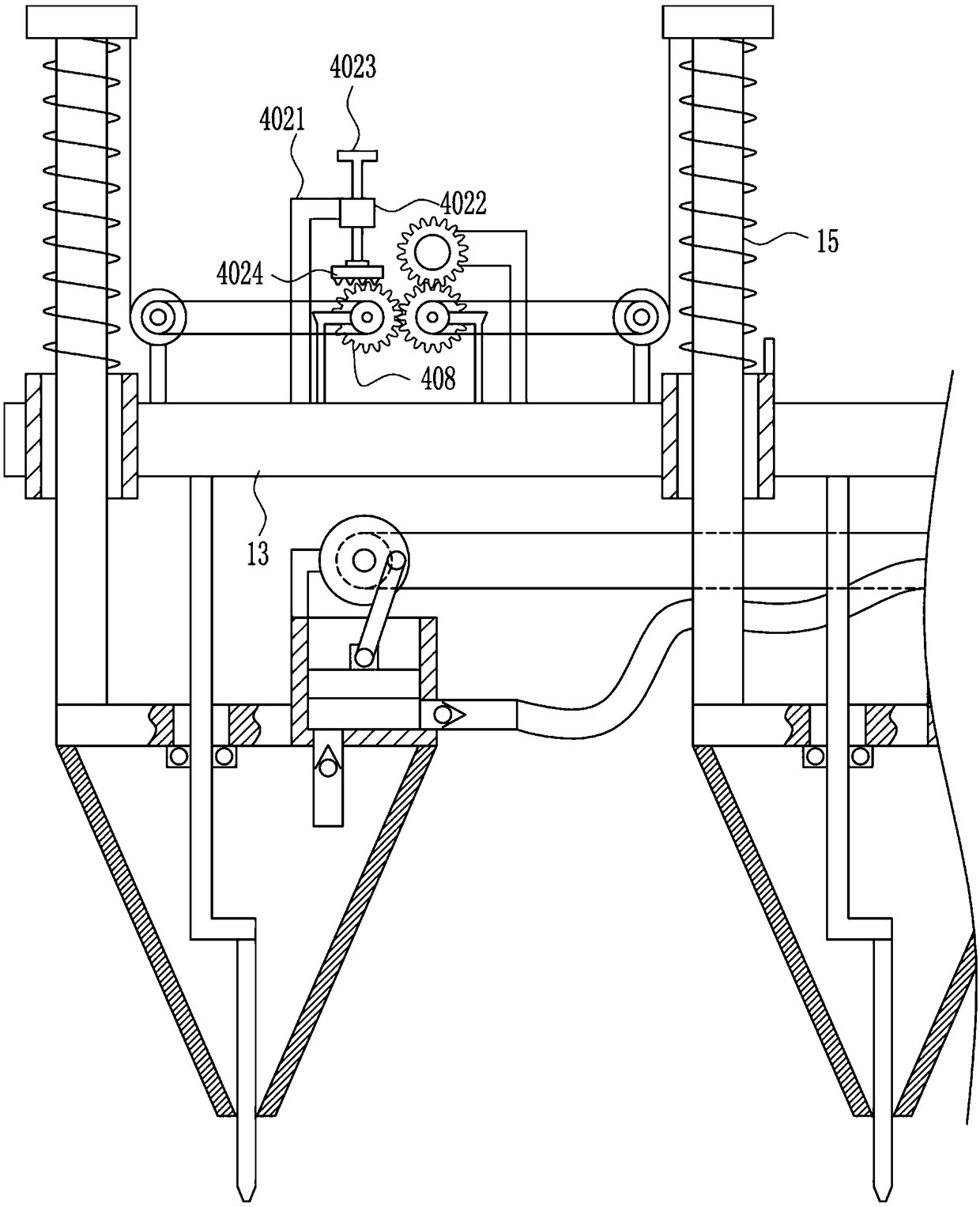

[0026] A kind of equipment for soil restoration and upgrading, such as Figure 1-5 As shown, it includes a bottom plate 1, a vehicle frame 2, a first bearing seat 3, a rotating rod 4, a mounting plate 5, a first guide rail 6, a first guide sleeve 7, a second bearing seat 8, a first screw rod 9, a first A nut 10, an L-shaped plate 11, a material box 12, a connecting plate 13, a second guide sleeve 14, a second guide rail 15, a handle 16, a baffle plate 17, a cone bucket 18, a piston cylinder 19, a first one-way valve 20, Second one-way valve 21, infusion tube 22, piston block 23, L-shaped block 24, first electric wheel 25, first runner 26, first drive bar 27, rotating disk 28, rocking bar 29, the first L-shaped bar 30. The sealing ring 31 and the stop rod 32, the vehicle frame 2 is installed on the lower side of the bottom plate 1, the first bearing seat 3 is connected to the inner middle of the bottom plate 1, the first bearing seat 3 is connected to the rotating rod 4, and th...

Embodiment 2

[0028] A kind of equipment for soil restoration and upgrading, such as Figure 1-5As shown, it includes a bottom plate 1, a vehicle frame 2, a first bearing seat 3, a rotating rod 4, a mounting plate 5, a first guide rail 6, a first guide sleeve 7, a second bearing seat 8, a first screw rod 9, a first A nut 10, an L-shaped plate 11, a material box 12, a connecting plate 13, a second guide sleeve 14, a second guide rail 15, a handle 16, a baffle plate 17, a cone bucket 18, a piston cylinder 19, a first one-way valve 20, Second one-way valve 21, infusion tube 22, piston block 23, L-shaped block 24, first electric wheel 25, first runner 26, first drive bar 27, rotating disk 28, rocking bar 29, the first L-shaped bar 30. The sealing ring 31 and the stop rod 32, the vehicle frame 2 is installed on the lower side of the bottom plate 1, the first bearing seat 3 is connected to the inner middle of the bottom plate 1, the first bearing seat 3 is connected to the rotating rod 4, and the...

Embodiment 3

[0031] A kind of equipment for soil restoration and upgrading, such as Figure 1-5 As shown, it includes a bottom plate 1, a vehicle frame 2, a first bearing seat 3, a rotating rod 4, a mounting plate 5, a first guide rail 6, a first guide sleeve 7, a second bearing seat 8, a first screw rod 9, a first A nut 10, an L-shaped plate 11, a material box 12, a connecting plate 13, a second guide sleeve 14, a second guide rail 15, a handle 16, a baffle plate 17, a cone bucket 18, a piston cylinder 19, a first one-way valve 20, Second one-way valve 21, infusion tube 22, piston block 23, L-shaped block 24, first electric wheel 25, first runner 26, first drive bar 27, rotating disk 28, rocking bar 29, the first L-shaped bar 30. The sealing ring 31 and the stop rod 32, the vehicle frame 2 is installed on the lower side of the bottom plate 1, the first bearing seat 3 is connected to the inner middle of the bottom plate 1, the first bearing seat 3 is connected to the rotating rod 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com