Dual-workstation connector automatic assembling device

An automatic assembly and connector technology, which is used in assembly machines, devices for coating liquid on surfaces, metal processing, etc. Needle assembly efficiency, improved assembly efficiency, and the effect of realizing flexible parameter setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] The invention provides an automatic assembly device for duplex station connectors, which realizes the assembly of sockets of different specifications and the assembly of insulators, and the addition of a glue filling mechanism effectively avoids the low production efficiency of manual assembly, low consistency, and low accuracy of multi-step separate production and assembly. advanced questions.

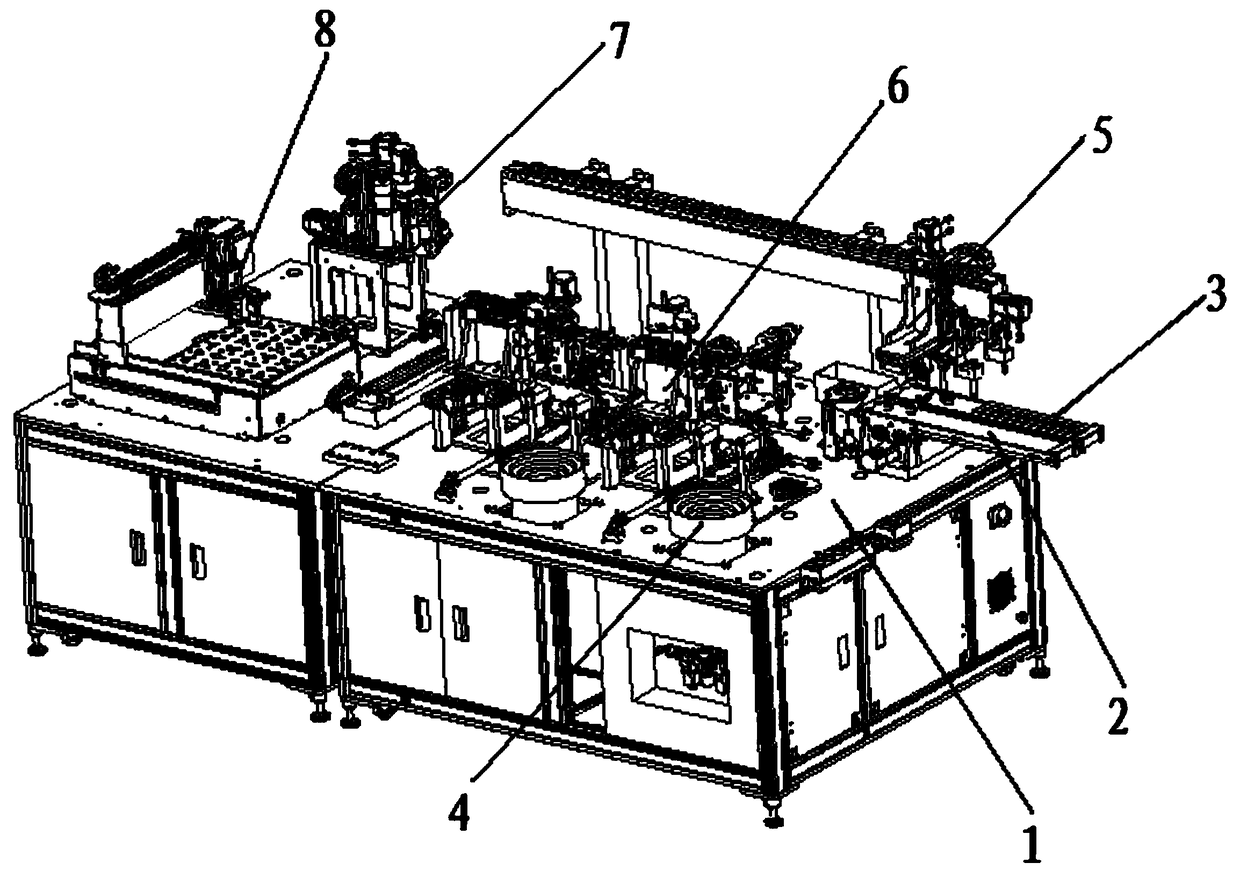

[0031] Such as figure 1 Shown is the overall schematic diagram of the automatic assembly device. It can be seen from the figure that an automatic assembly device for duplex station connectors includes a bottom plate 1, a shell feeding mechanism 2, an insulator feeding module 3, two pin feeding mechanisms 4, Handling assembly mechanism 5, 2 pin assembly mechanisms 6, automatic glue filling mechanism 7 and product automatic collection mechanism 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com