Irradiated thin-wall aluminium pipe splitting device and splitting method

A cutting device and thin-walled technology, which is applied in the direction of sampling devices, large fixed members, maintenance and safety accessories, etc., can solve the problems of physical property damage and research impact, and achieve the effect of ensuring the processing quality and physical properties without damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

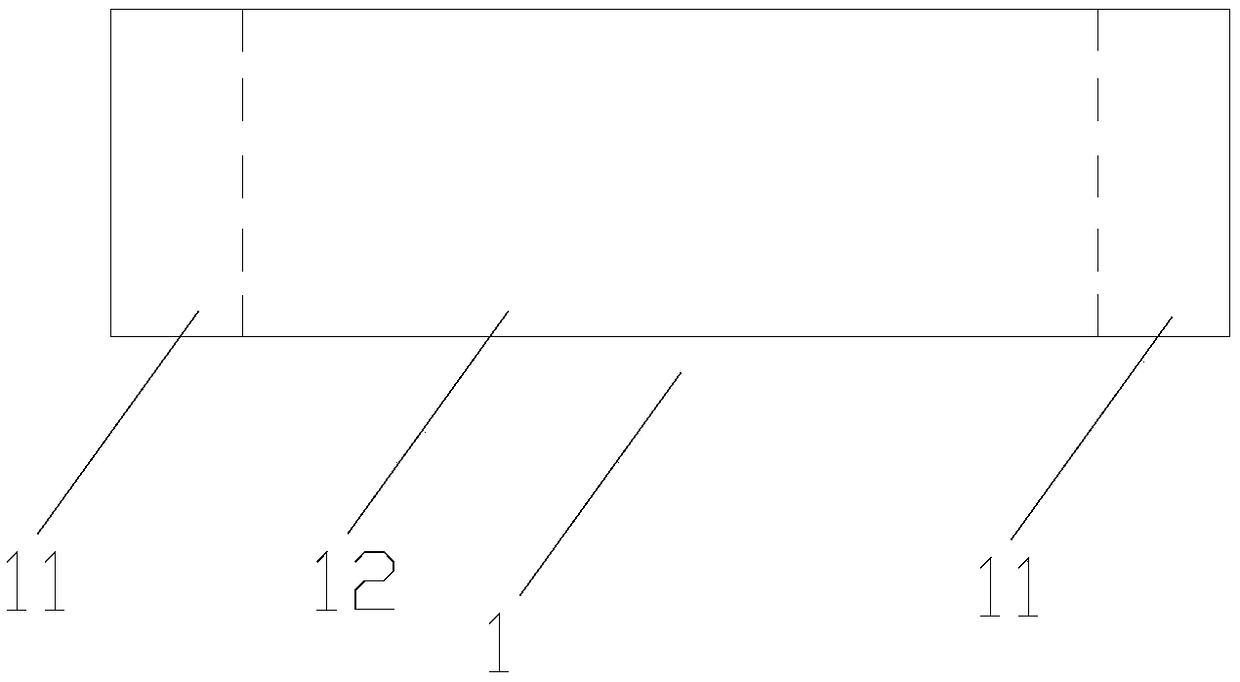

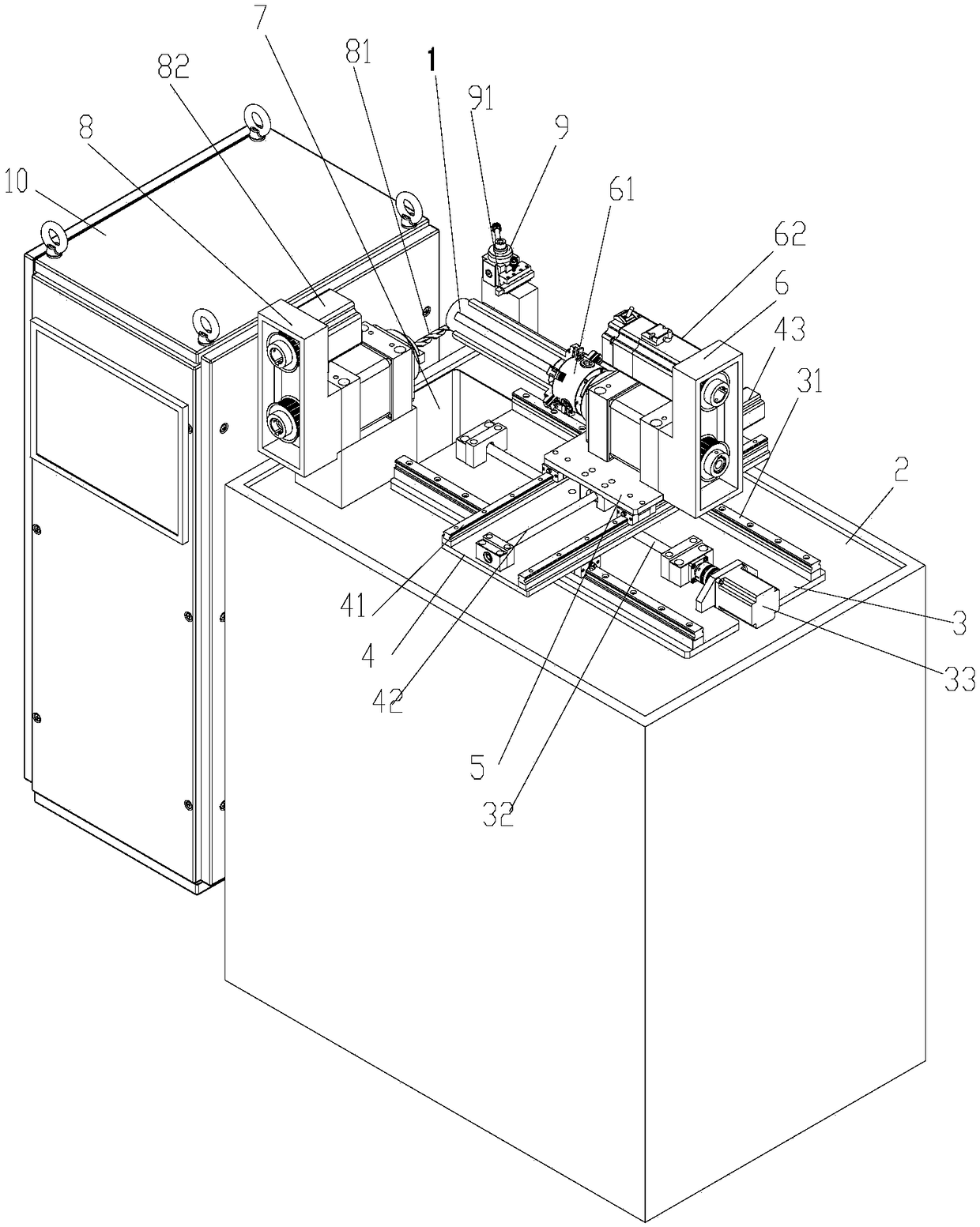

[0033] Such as figure 1 As shown, the current experimental requirements for irradiating thin-walled aluminum tubes are as follows: first cut off the two ends 11 of the thin-walled aluminum tube 1 whose surface quality is unqualified, and the remaining part of the tube after cutting, that is, the cut part 12, needs to be cut along the axial direction. Be equally divided into several pieces; Therefore, in order to complete the cutting work of the thin-walled aluminum tube 1, such as Figure 2 to Figure 3 As shown, the present invention discloses a cutting device for irradiated thin-walled aluminum tubes, which at least includes a bed 2; the bed 2 is provided with a transverse mounting plate 3;

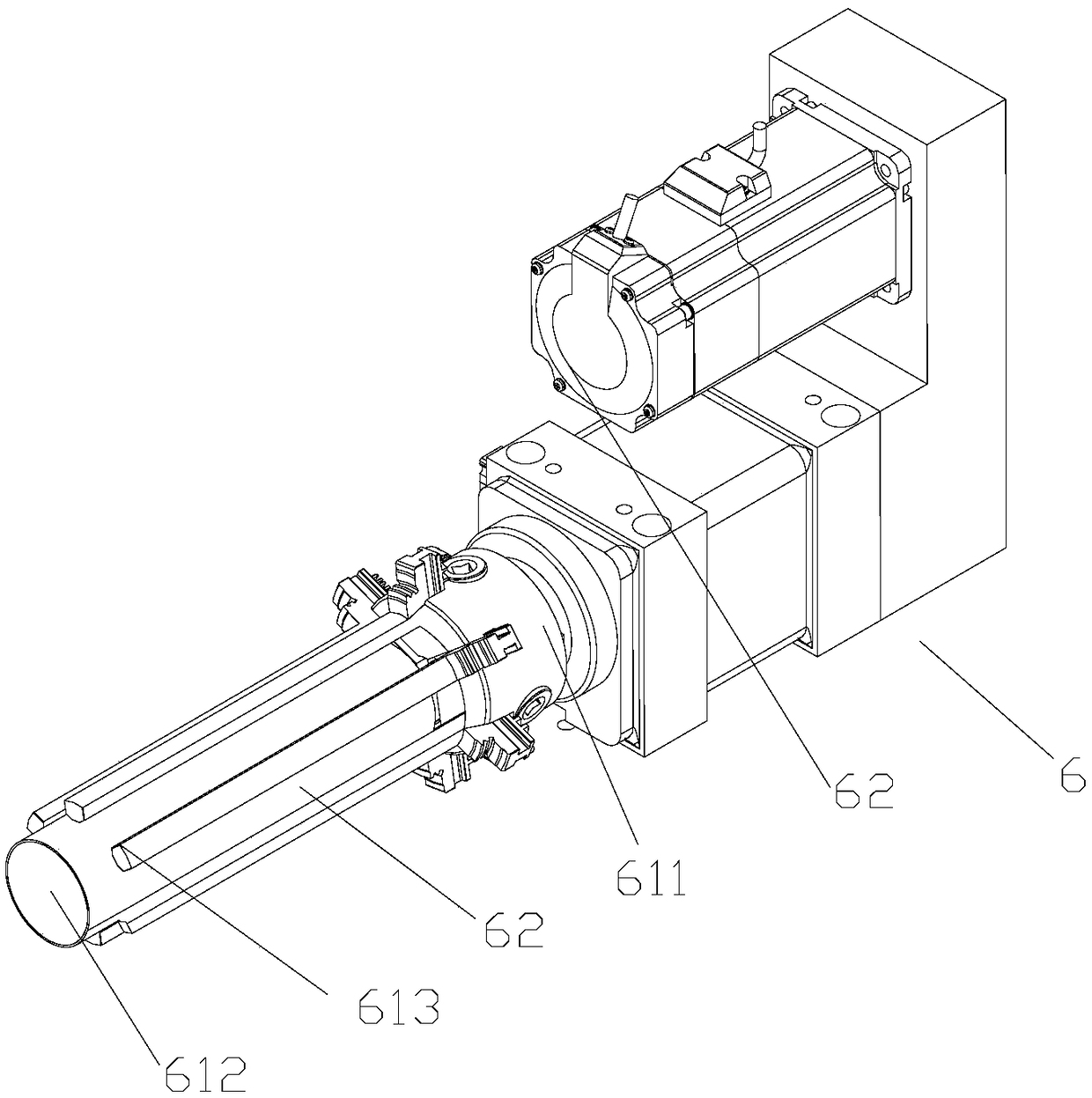

[0034] Two parallel transverse guide rails 31 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com