Nut stereo imaging detection device and method

A technology of three-dimensional imaging and detection device, which is used in optical testing of flaws/defects, material analysis using radiation, etc., can solve the problems of unrealistic manual detection, low detection efficiency, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

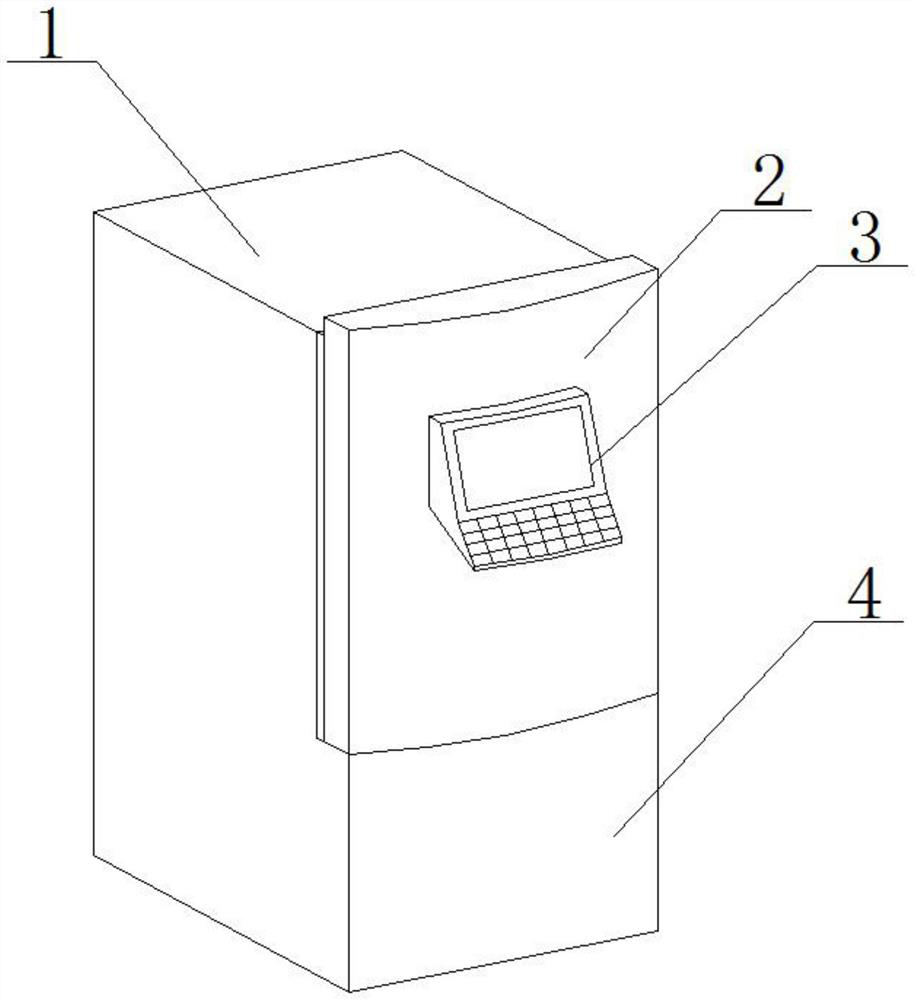

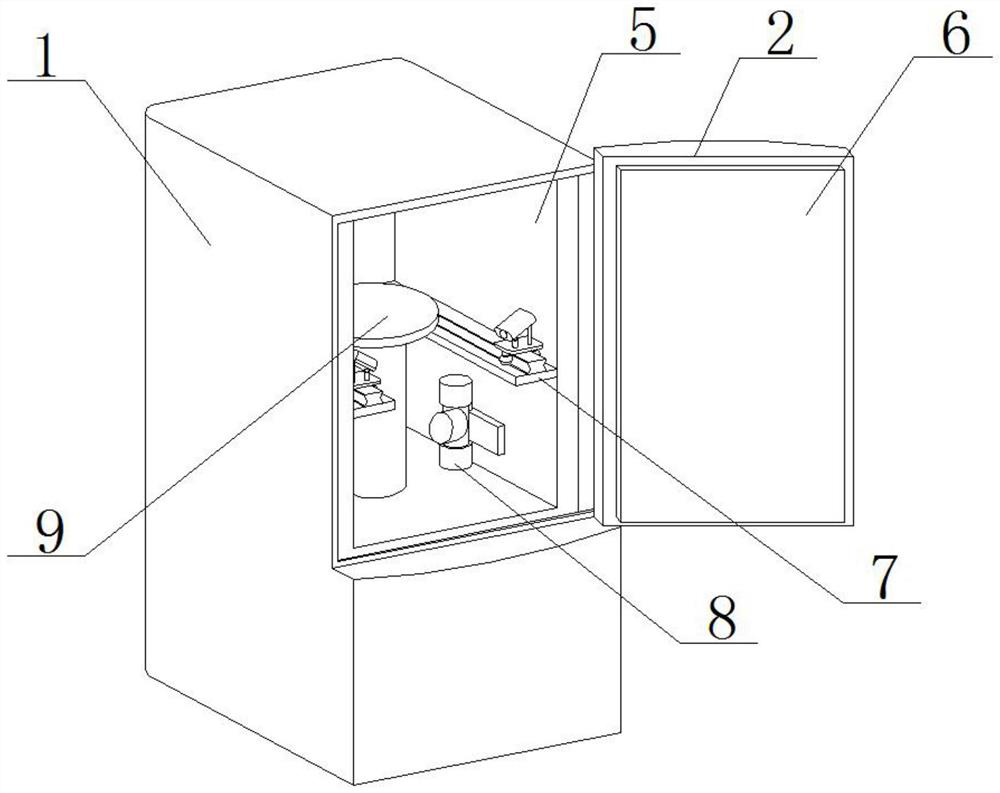

[0038] see Figure 1-Figure 9, the present invention provides a nut three-dimensional imaging detection device, including a data acquisition module, a data storage module, a data matching module and a central processing unit, the data acquisition module includes an X-ray machine 8 and a camera 12, and the data storage module is a bolt model library, including For the data of multiple different types of nuts, the data matching module compares and matches the collected data with the stored data, and the central processing unit is installed in the control panel 3;

[0039] A protective door 2 is fixedly installed on the front end of the outer shell 1, a control panel 3 is fixedly installed on the front end of the protective door 2, a base 4 is fixedly installed under the protective door 2, and a first lead plate 5 is fixedly installed on the right end inside the outer shell 1. A second lead plate 6 is fixedly installed on the protective door 2, a partition 7 is fixedly installed ...

Embodiment 2

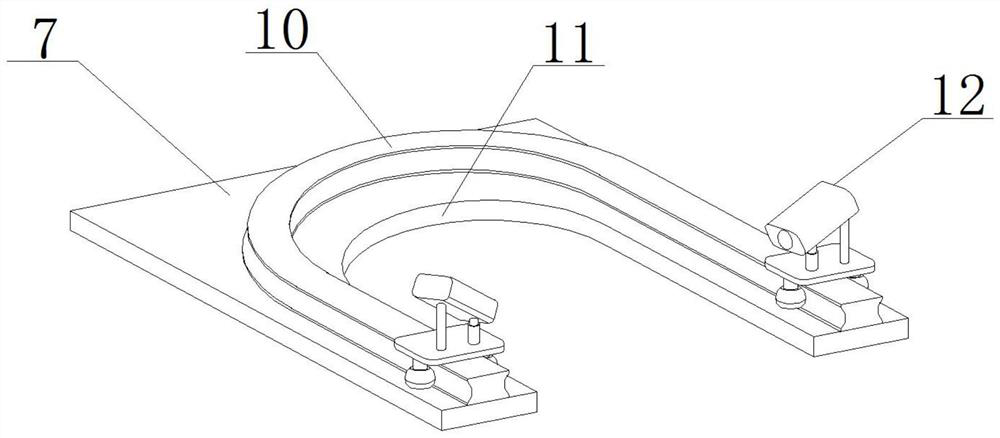

[0043] The first lead plate 5 is provided with five groups altogether, and the first lead plate 5 of five groups is respectively installed in the left end, the right end, the rear end, the top end and the bottom end of the outer casing 1, wherein the first lead plate 5 of the left end, the right end and the rear end There are card slots at the middle position of the center, and the partition plate 7 is engaged and connected with the outer casing 1 through the chute; there are several groups of cameras 12, and several groups of cameras 12 are connected to the U-shaped track 10 by sliding. The groove 11 is set at the middle position of the partition 7, and the U-shaped groove 11 runs through the front end and the upper and lower ends of the partition 7. The width of the U-shaped groove 11 is greater than the diameter of the turntable 9; each group of cameras 12 is correspondingly provided with a set of Fixed plate 15, the bottom end of every group of fixed plate 15 is provided wi...

Embodiment 3

[0046] The round groove 30 is connected to the ejector pin 33 through a snap fit, and the tooth groove 31 and the cavity 32 are connected through a snap fit. The weighing pan 38 is fixedly connected to the push rod 33 by welding, and the second motor 37 is installed at the center of the weighing pan 38 .

[0047] In the present embodiment, weighing disc 38 at first resets the weight of rotating disc 9 to zero, after putting on nuts, calculates the quality of nuts, compares with the data stored in the database, and detects whether the weight of nuts is qualified, then passes through second motor 37 Work, drive the turntable 9 and the nut on it to rotate, facilitate the camera 12 to complete the data reading work on the nut.

[0048] A detection method of a nut stereoscopic imaging detection device, the detection method specifically includes the following steps:

[0049] Step 1: Enter the data models of different types of nuts in the data storage module;

[0050] Step 2: Open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com