Remaining material collecting and spreading integrated machine for pasture

An all-in-one machine and leftover material technology, applied in the direction of conveyors, conveyor objects, loading/unloading, etc., can solve the problems of increasing breeding production costs, reducing work efficiency, wasting time and labor, etc., to achieve convenient operation, labor saving, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

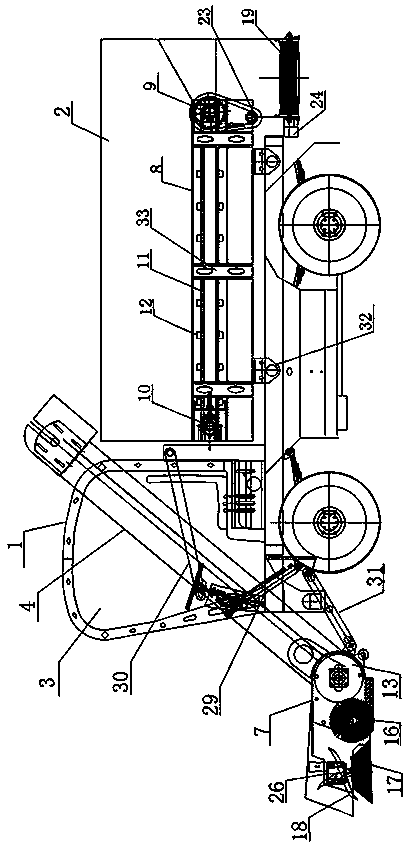

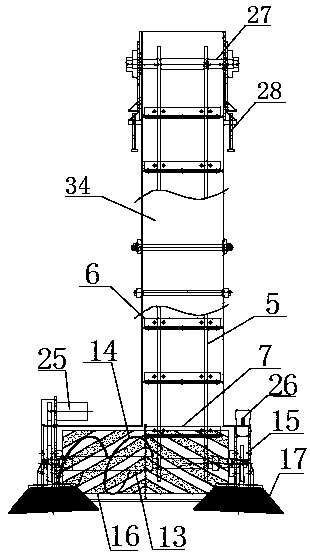

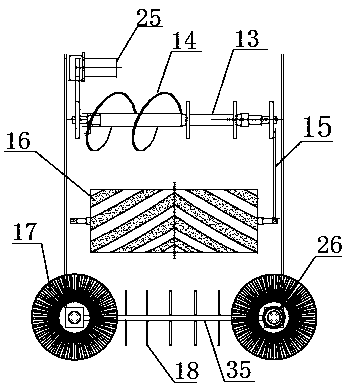

[0019] The accompanying drawing is a specific embodiment of the present invention. This embodiment includes a vehicle body 1 , a box body 2 is installed above the rear part of the vehicle body 1 , a cab 3 is arranged above the front part of the vehicle body 1 , and a feeding pipe for feeding grass to the box body 2 is arranged above the front part of the vehicle body 1 4. A scraper chain I5 is installed in the feeding pipe 4, a number of scrapers I6 are installed on the scraper chain I5, a bucket 7 is installed at the front end of the feeding pipe 4, and a The scraper frame 8, a driving shaft 9 and a driven shaft 10 are arranged between the two ends of the two scraper frames 8, a scraper chain II11 is connected between the driving shaft 9 and the driven shaft 10, and between the two scraper chains II11 There is a scraper II12, an aggregate auger shaft 13 is installed in the bucket 7, an auger blade 14 is installed on the aggregate auger shaft 13, and the scraper chain I5 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com