A kind of excavation construction method for chambers in special strata

A construction method and chamber technology, applied in underground chambers, earthwork drilling, shaft equipment, etc., can solve problems such as large engineering volume, weak excavation support, and easy landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

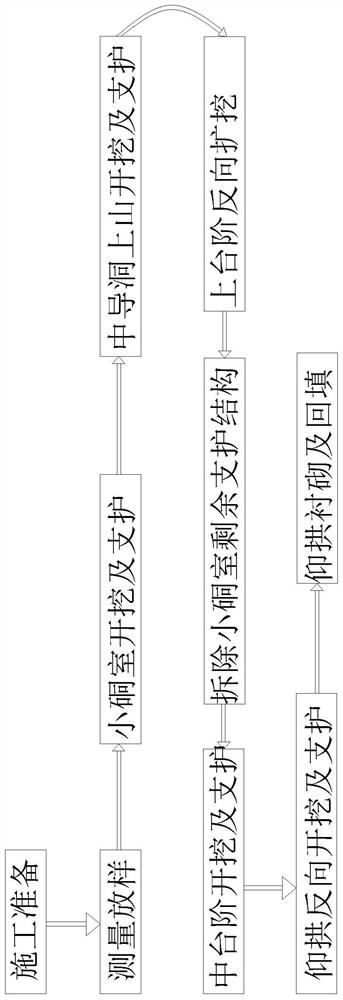

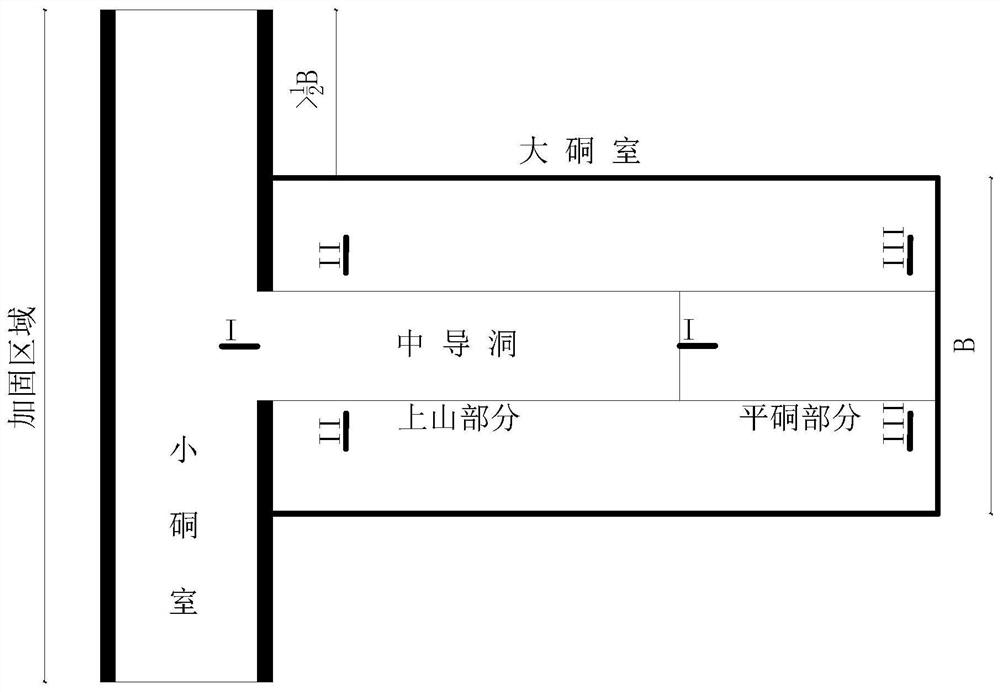

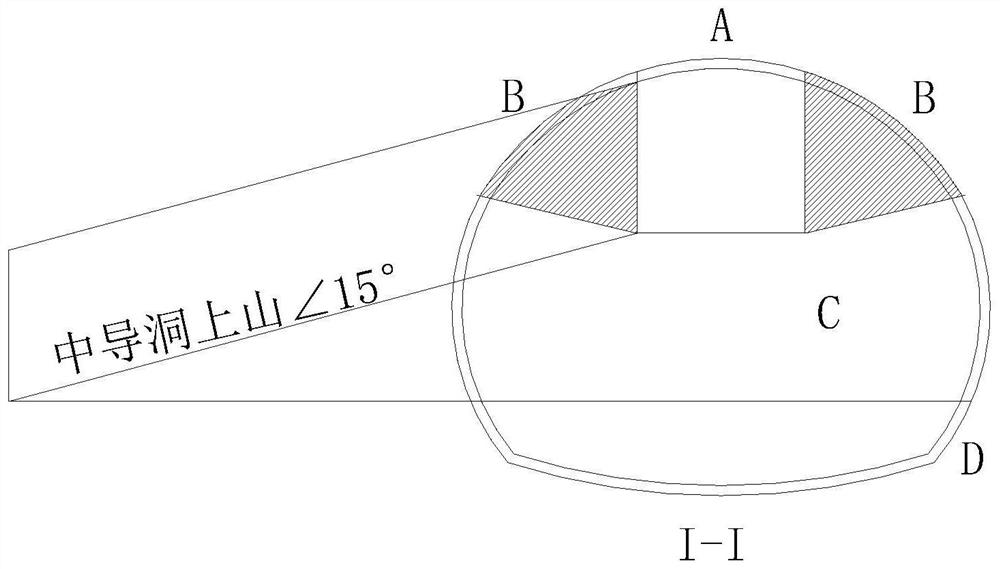

Method used

Image

Examples

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 is that this embodiment also provides an overall construction plan for the support of the large chamber hall.

[0068] The overall construction scheme of hall support

[0069] Such as Figure 4 As shown, (1) design a pair of integral steel mold trolley at the 6-meter span of the main body. The trolley is composed of two parts, each of which is 3 meters long and can be docked.

[0070] (2) The hall is supported by full scaffolding in the middle, 20# industrial steel columns on the wall, and 12# industrial steel arches on the arch form the main body of the support system, and the joint force is achieved through screw jacks. Shaped steel formwork is used for the formwork arch, and large steel-wood combination formwork for the side walls.

[0071] (3) Other sections and branch holes adopt I-beam assembled formwork, shaped steel formwork for arches, and large shaped steel formwork for side walls.

[0072] (4) Commer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com