A large-pitch tapered external thread detection device and method

A detection method and external thread technology, which is applied in the field of large-pitch tapered external thread detection devices, can solve problems such as the inability to accurately obtain large-pitch tapered thread sizes, and achieve online fast and high-precision detection, contour recognition and size conversion algorithms The effect of simplicity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

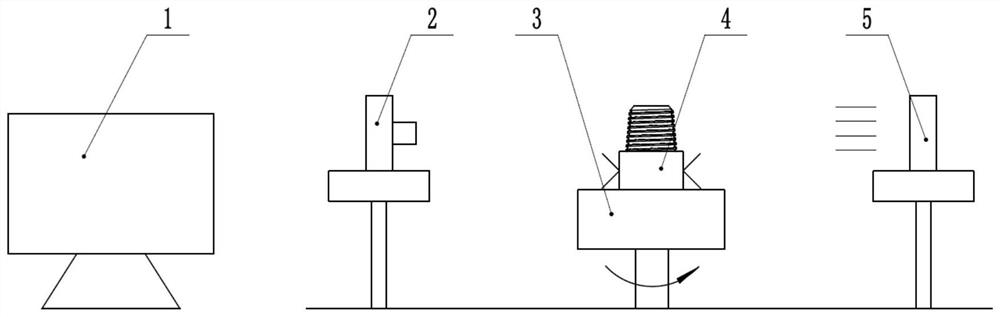

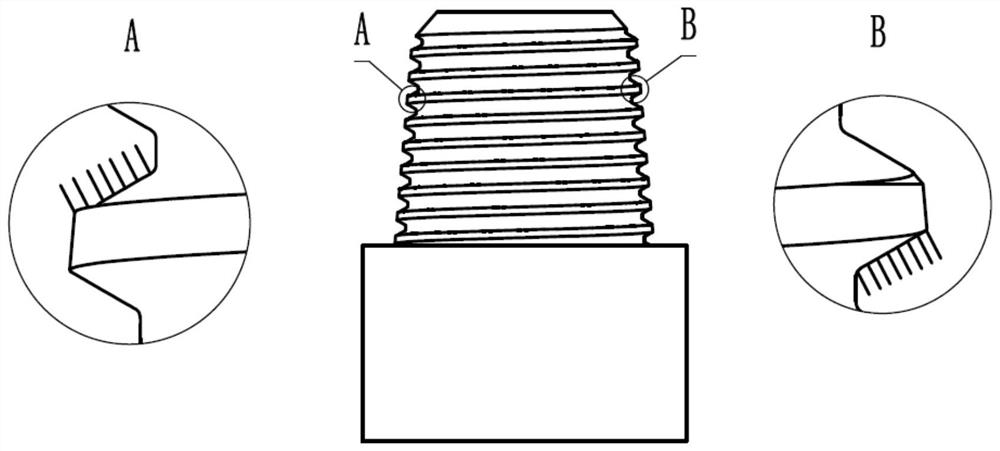

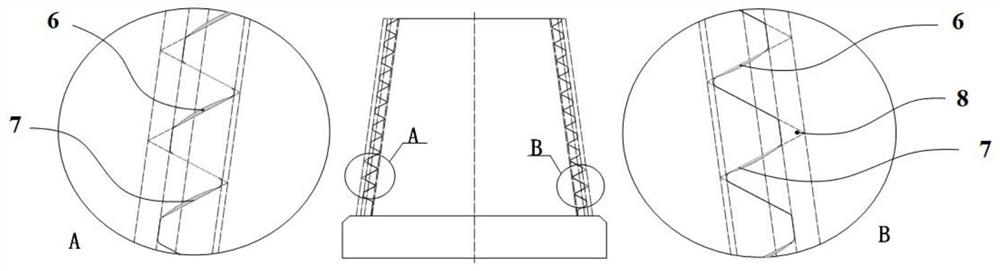

[0067] Such as figure 1 As shown, the present embodiment provides a large-pitch tapered external thread detection device, including a workpiece fixing assembly 3 and an imaging assembly 2; also includes a detection assembly 1 and a light source assembly 5; the light source assembly 5 is a plane light source, used for orientation The image component 2 provides a light source; the detection component 1 includes a display interface, a data storage system, a thread profile extraction module, and a thread reverse calculation module to extract thread image profiles, calculate thread processing parameters and determine results; specifically, the thread profile extraction module and The thread reverse calculation module is used to process the thread image, measure the size of the thread image and inverse calculation, so as to obtain the thread processing parameters, make judgments on the processing results, and record the detection results in the data storage system.

[0068] Specific...

Embodiment 2

[0070] Such as Figure 1 to Figure 5 As shown, this embodiment also provides a detection method using the large-pitch tapered external thread detection device, including the following steps:

[0071] Step S1: In the display interface of the detection component, input the thread design parameters of the workpiece to be tested and the tool parameters used for thread processing; the thread design parameters include thread major diameter, pitch diameter, thread pitch, tooth profile angle, total thread length and taper, etc.;

[0072] Step S2: placing the workpiece to be measured in the workpiece fixing assembly, adjusting the workpiece fixing assembly so that the light source assembly, the thread of the workpiece to be measured, and the imaging assembly are on the same horizontal line;

[0073] Step S3: The image acquisition component collects the image of the thread of the workpiece to be tested, and transmits it to the detection component;

[0074] Step S4: The detection compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com