Tight-buffered optical fiber and making method thereof

A technology of tight-buffered optical fibers and production methods, applied in the directions of cladding optical fibers, optical waveguide light guides, light guides, etc., can solve the problems of easily damaging the optical fiber body, reducing the stripping force, easy separation and slippage, etc., so as to avoid damage to the optical fiber body. , Improve reliability and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

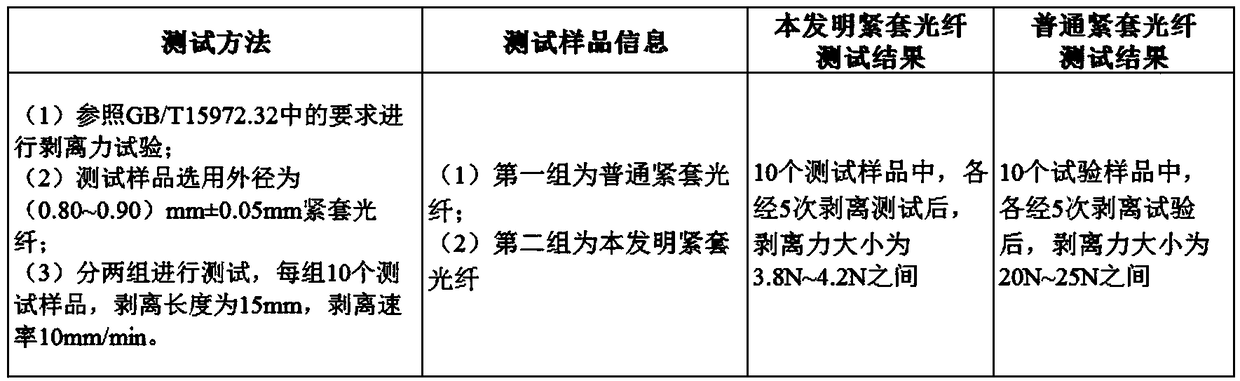

[0036] At present, the tight sleeve layer is generally made of materials such as TPEE (thermoplastic polyester elastomer) or PA12 (nylon 12). Due to the characteristics of materials such as TPEE and PA12, they have strong adhesion to the surface of the optical fiber and require a large The intensity of stripping the tight sleeve layer will cause certain difficulties for reprocessing. Moreover, in the process of stripping, the fiber body will be easily damaged, which will affect the product performance.

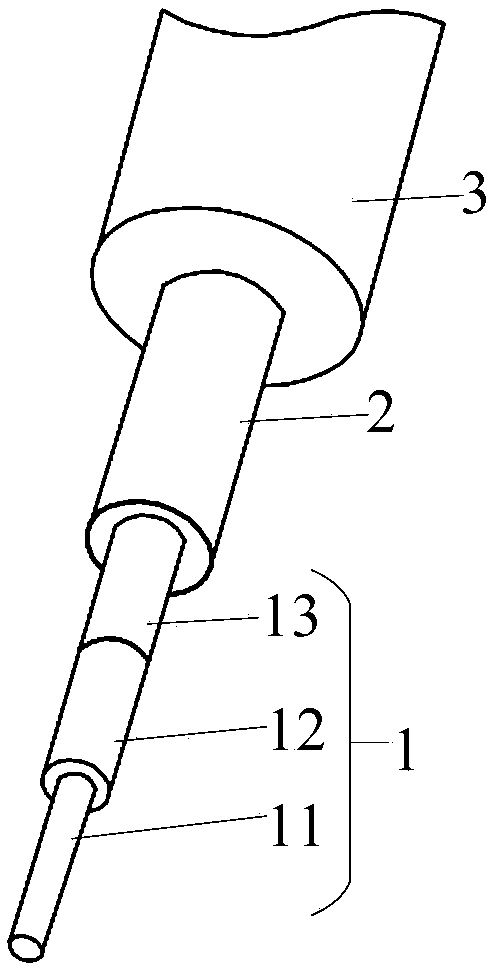

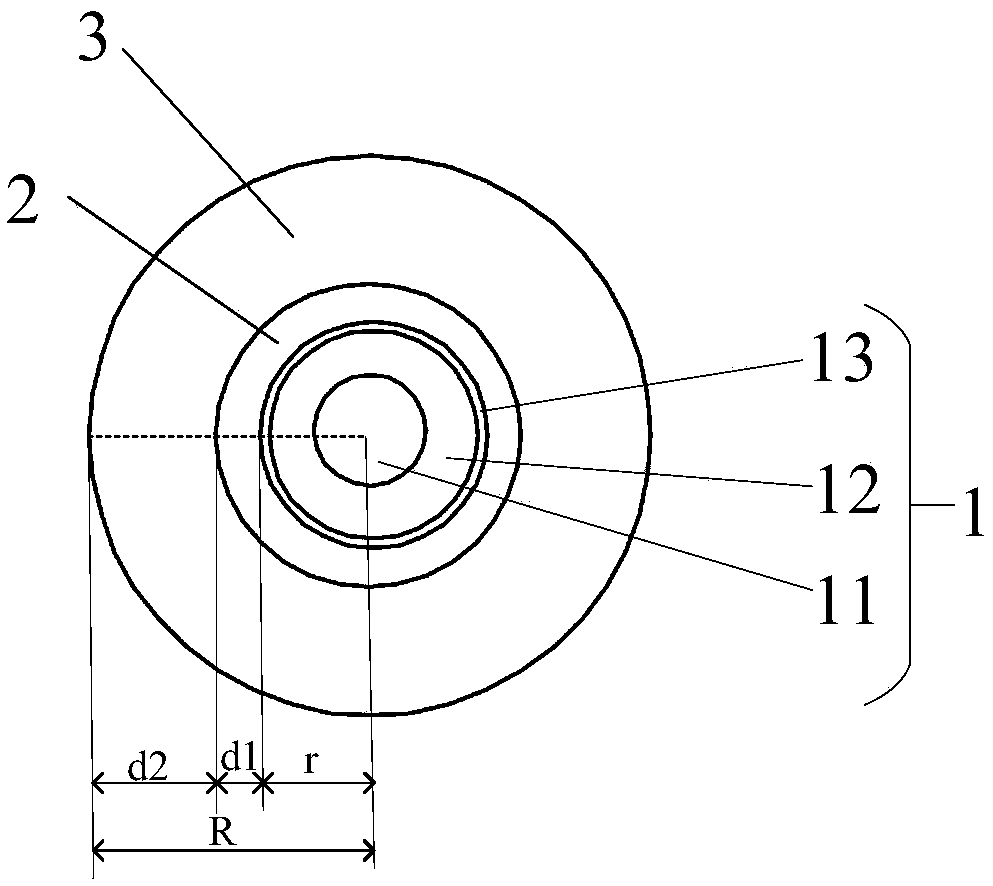

[0037] In order to solve the foregoing problems, the present embodiment provides a tight sleeve optical fiber, which is combined below figure 1 and figure 2 , to specifically illustrate one of the realizable manners of the tight-buffered optical fiber of this embodiment. in, figure 1 In order to facilitate the display of the positional relationship between different layers, the tight-buffered fiber is partially stripped.

[0038] The tight-buffered optical fiber of this em...

Embodiment 2

[0052] The present invention also provides a method for manufacturing a tight-buffered optical fiber, which is suitable for the tight-buffered optical fiber in the first embodiment above.

[0053] Combine below Figure 4 and Figure 5 , to specifically illustrate one of the realizable ways of the method for manufacturing the tight-buffered optical fiber of this embodiment. The manufacturing method of the tight-buffered optical fiber comprises the following steps:

[0054] Step 401: Use a coating device to coat a separation layer on the surface of the optical fiber body, wherein a predetermined separation agent is contained in the coating device.

[0055] Wherein, the optical fiber body includes a core, a cladding and a coating layer, the cladding is arranged on the periphery of the fiber core, the coating is arranged on the periphery of the cladding, and the separation layer is coated on the surface of the coating. The optical fiber body may be prefabricated, or prepurchas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com