Line-hanging inspection robot

A technology for inspection robots and lines, which is applied in the direction of manipulators, overhead lines/cable equipment, manufacturing tools, etc., can solve problems such as the need to adjust the center of gravity, the long time to overcome obstacles, and the complex structure of inspection robots, so as to save the need to adjust the center of gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

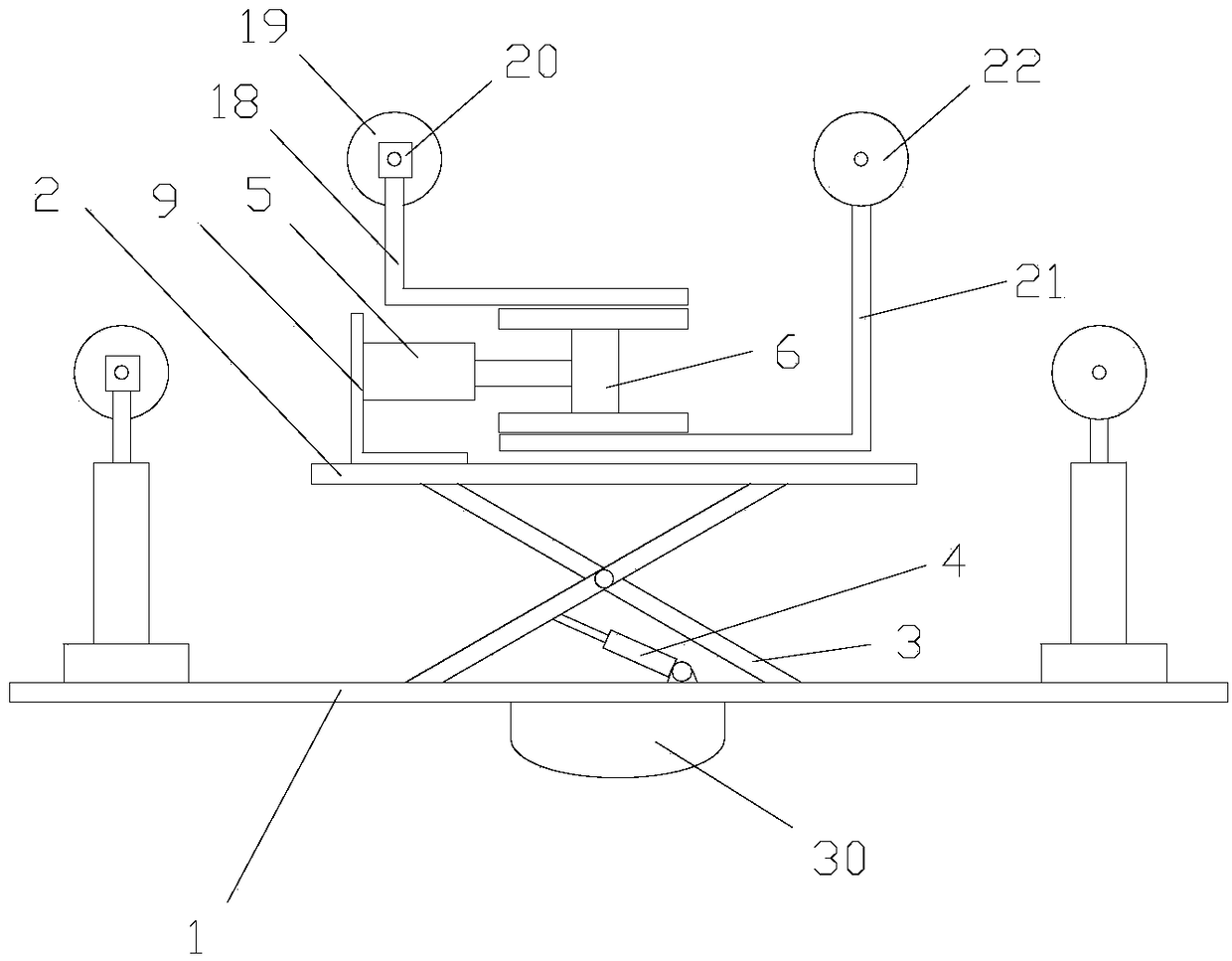

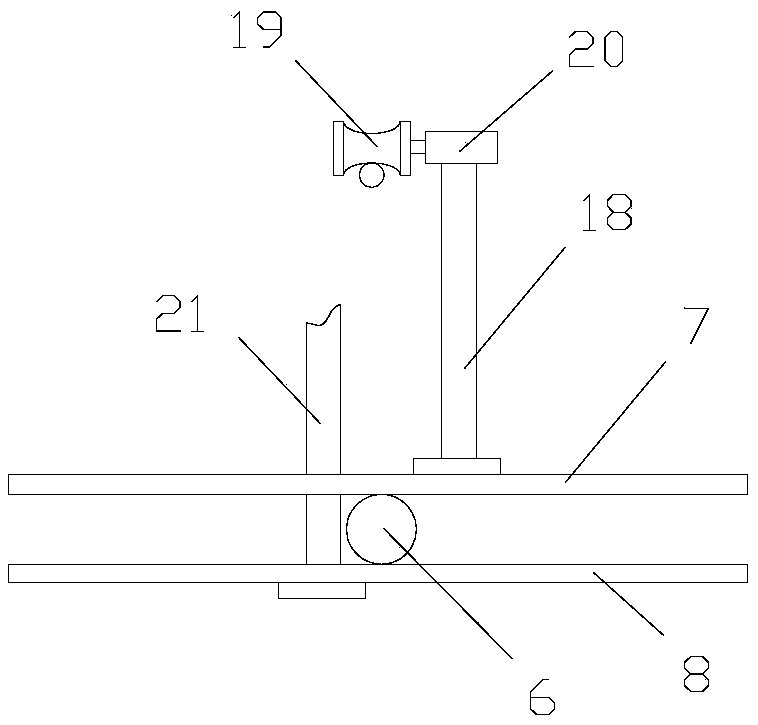

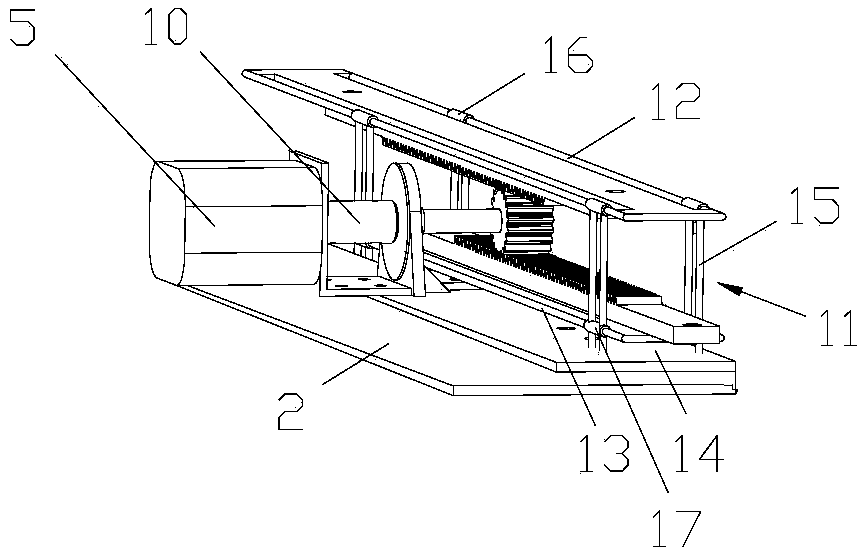

[0063] combine figure 1 As shown, a hanging line inspection robot includes a controller (not shown), a base plate 1, a lifting mechanism, a traversing mechanism mounting plate 2, a traversing mechanism, a front working arm, a rear working arm, and a front obstacle-surpassing mechanical arm and the rear obstacle-surpassing robotic arm.

[0064] Wherein, the controller can be, for example, a programmable logic controller such as a single-chip microcomputer or a PLC controller.

[0065] The bottom plate 1 can be, for example, a square plate, on which bolt holes are provided for installing other components.

[0066] The lifting mechanism is installed (by bolts) on the upper surface of the base plate 1 and is located in the middle of the base plate 1 . The lifting mechanism can realize the synchronization of the lifting action of the front working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com