Process agent adding device

A dosing device, a process-based technology, applied in the directions of transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of impervious drug curing, small capacity of the dissolving box, and large equipment volume, etc. The effect of stirring and curing time, preventing the aging process, and convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

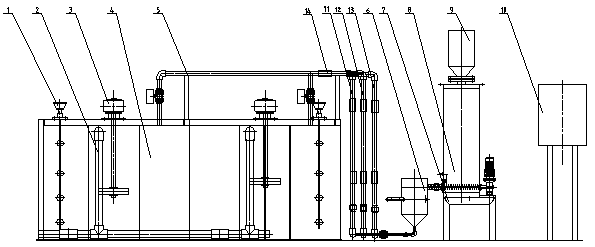

[0013] A process-based dosing device, including a liquid level switch 1, an overflow vent pipe 2, a mixer 3, a solution tank system 4, a medicine feeding pipe 5, a Venturi pre-mixing barrel 6, a frame 7, a barrel and quantitative dosing Machine 8, vacuum feeding machine 9, control box 10, drug delivery pipe, pipeline pump, curing process curved tube A11, curing process curved tube B 12, curing process curved tube C 13, static mixing tube 14, the described medicine feeding Venturi pre-mixing barrel 6 is arranged between pipe 5 and barrel and quantitative dosing machine 8; Described drug-dissolving box system 4 is provided with drug-discharging ball valve on the drug-dissolving box, and described drug-feeding pipe 5 and drug-discharging The pipe is connected to the drug-dissolving box, and a heater is fixed on the discharge pipe of the quantitative dosing machine. A liquid level sensor is installed in the drug-dissolving box to control feeding and water intake. The control box 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com