Detergent release device and washing machine

A detergent dispensing and detergent technology, which is applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems that the detergent cannot be fully dissolved or diluted, and it is inconvenient to manually dispense the detergent, so as to achieve high detergent utilization efficiency. , Detergent discharge thoroughly, the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

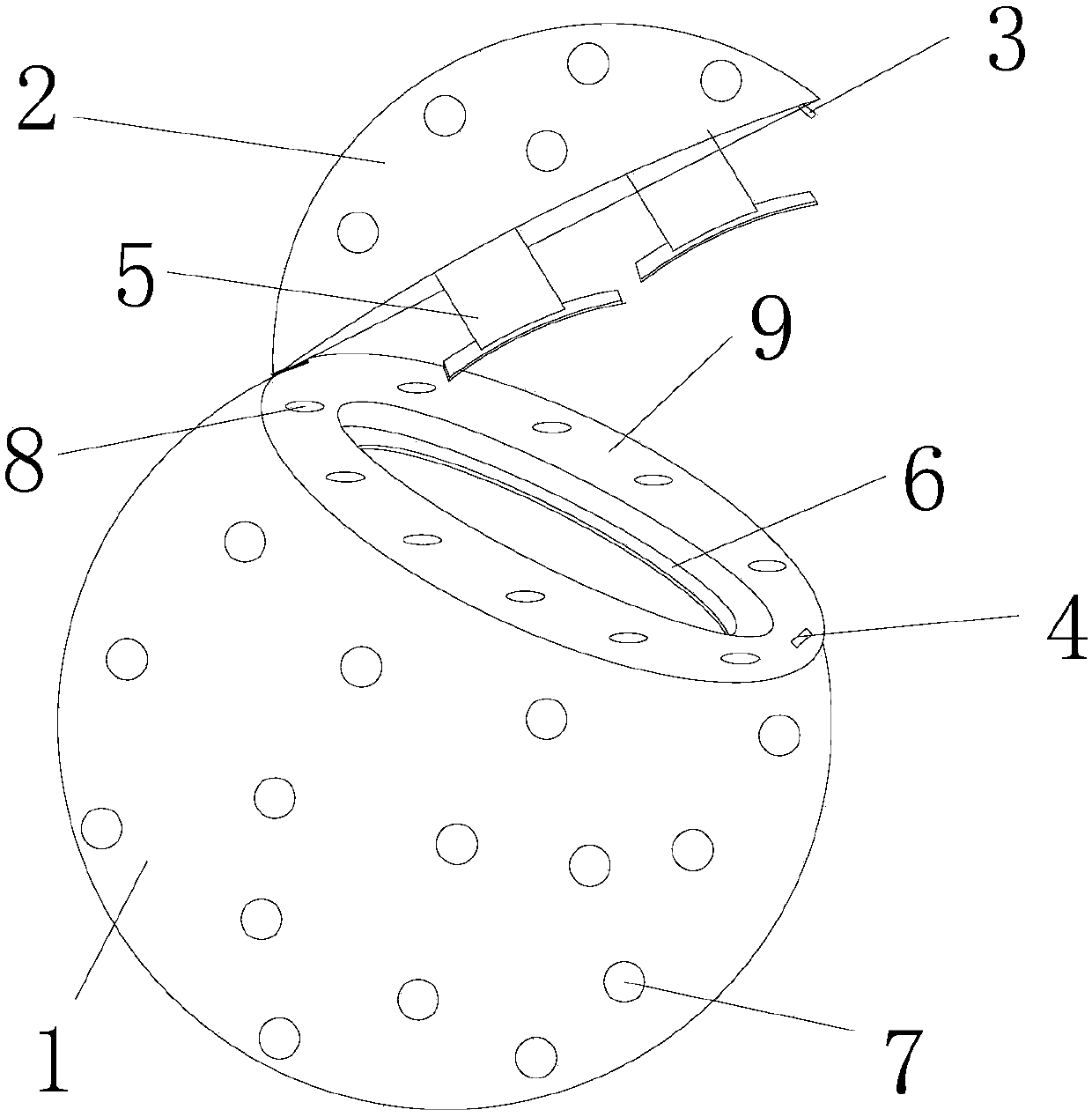

[0038] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the embodiment of the present invention introduces a detergent dispensing device, which includes a main body 1, which is hollow to form a housing cavity, an assembly surface 9 is provided at the opening of the main body 1, and the upper cover 2 can be opened and closed to cover On the assembly surface 9, the detergent containing device 12 is coaxially sleeved inside the main body 1, the detergent containing device 12 communicates with the accommodating chamber, and the surface of the main body 1 is arranged with a plurality of Connected liquid outlet 7.

[0039] In this embodiment, the assembly surface 9 is provided with a body opening, and the detergent containing device 12 is coaxially set in the accommodating chamber through the body opening; a plurality of through holes 8 are arranged on the assembly surface 9, and the through holes The hole 8 communicates with the accommodating cavities on both sides...

Embodiment 2

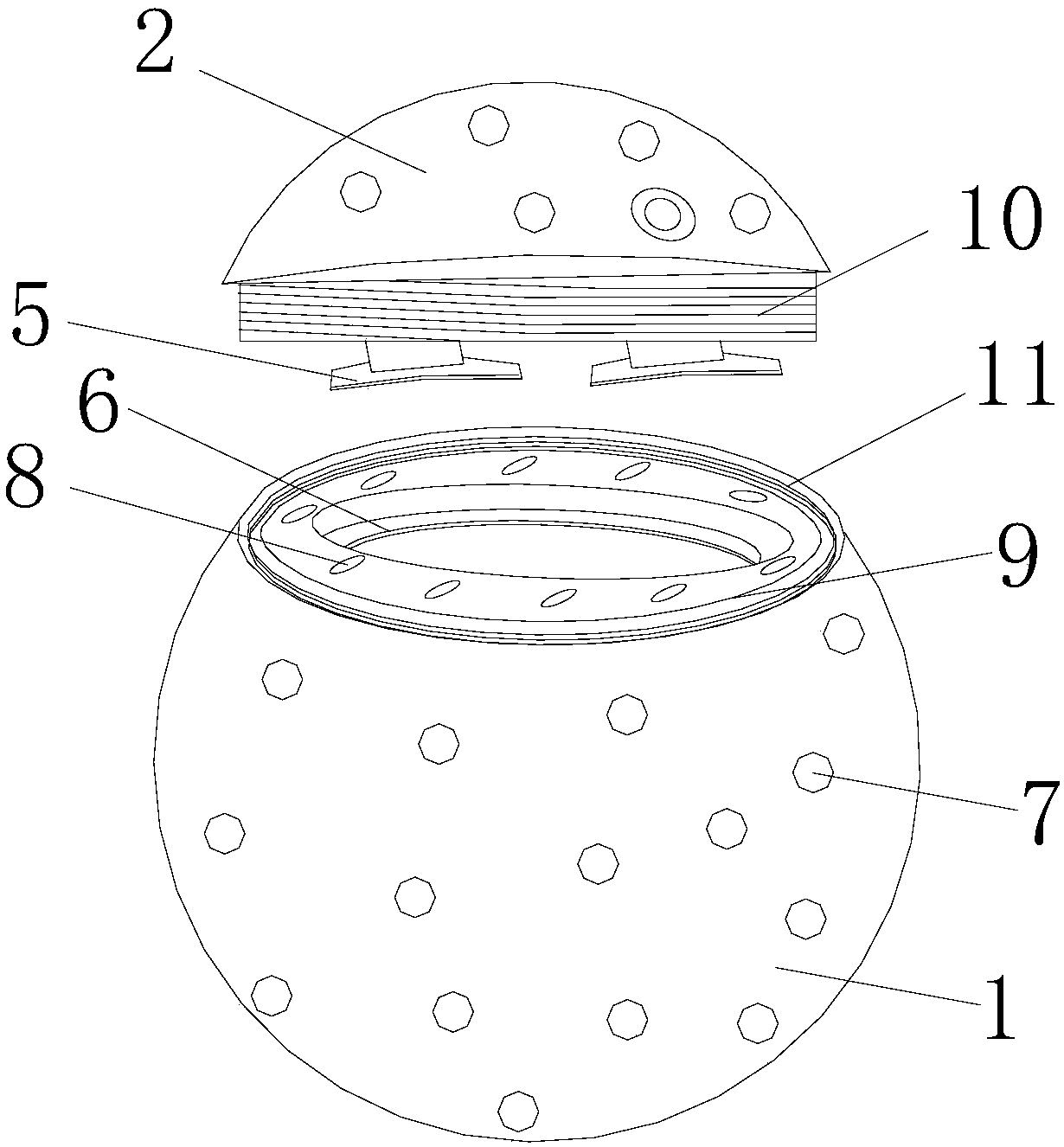

[0048] Such as image 3 , Figure 4a , Figure 4b As shown, another detergent dispensing device is introduced in the embodiment of the present invention, which includes a main body 1, which is hollow to form an accommodating cavity, and the detergent containing device 12 is coaxially sleeved inside the main body 1. The washing The agent holding device 12 is in communication with the containing chamber, and the surface of the body 1 is provided with a plurality of liquid outlets 7 connecting the containing chamber with the outside world.

[0049] In this embodiment, the detergent dispensing device is cylindrical.

[0050] In this embodiment, the body 1 is provided with an assembly surface 9, and a plurality of through holes 8 are arranged on the assembly surface 9. After the upper cover 2 is connected to the body 1, the through holes 8 connect the two sides of the assembly surface 9 The accommodating cavity is connected, and the assembly surface 9 is provided with a body ope...

Embodiment 3

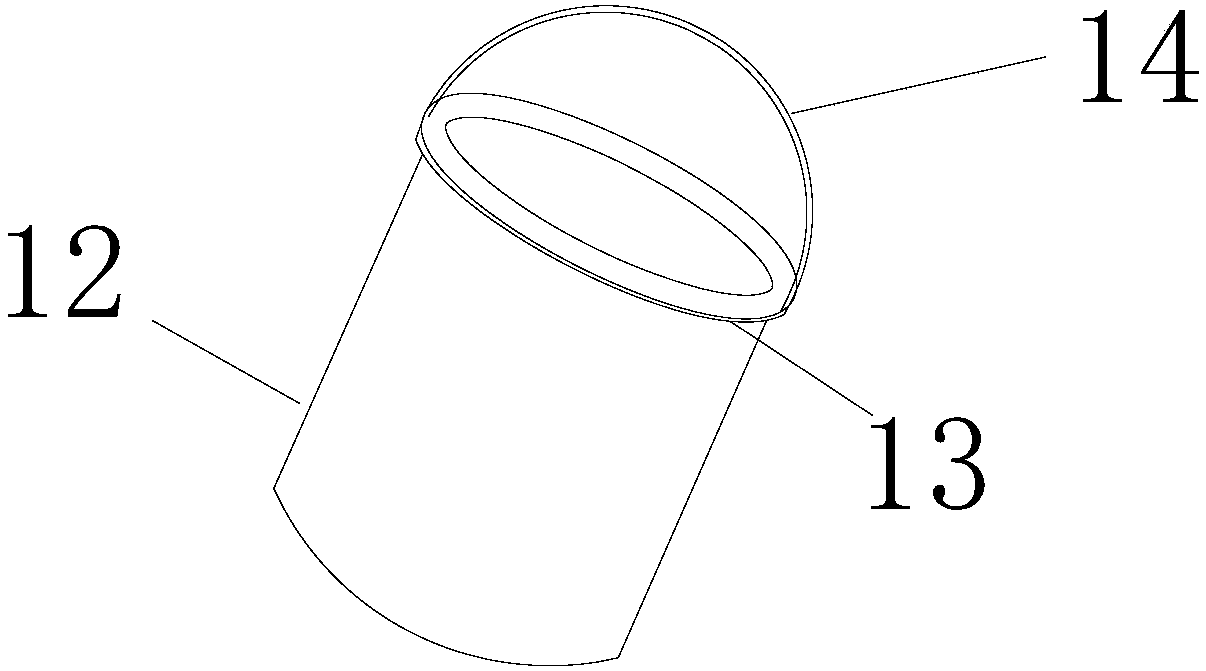

[0058] Such as Figure 6a , Figure 6b , Figure 7 As shown, this embodiment introduces a detergent dispensing device, which includes a main body 1 and an upper cover 2, the upper cover 2 is connected with the main body 1 to form an accommodating cavity, and the detergent holding device 12 is integrally formed with the main body 1 , the detergent containing device 12 is in communication with the containing cavity, and the surface of the body 1 and the upper cover 2 is provided with a plurality of liquid outlets 7 that communicate the containing cavity with the outside world.

[0059] In this embodiment, the detergent containing device 12 is arranged coaxially inside the body 1 , and there is a certain distance between the outer circumference of the detergent containing device 12 and the inner wall of the body 1 constituting the accommodating cavity.

[0060] In this embodiment, the upper end of the body 1 is provided with an assembly surface 9, the assembly surface 9 is at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com