Electromagnetic building brick crushing device

A crushing device, electromagnetic technology, applied in the field of construction equipment, can solve the problems of large wear of components, poor crushing effect, complex structure, etc., to achieve the effect of eliminating serious friction loss, improving crushing effect, and increasing the crushing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

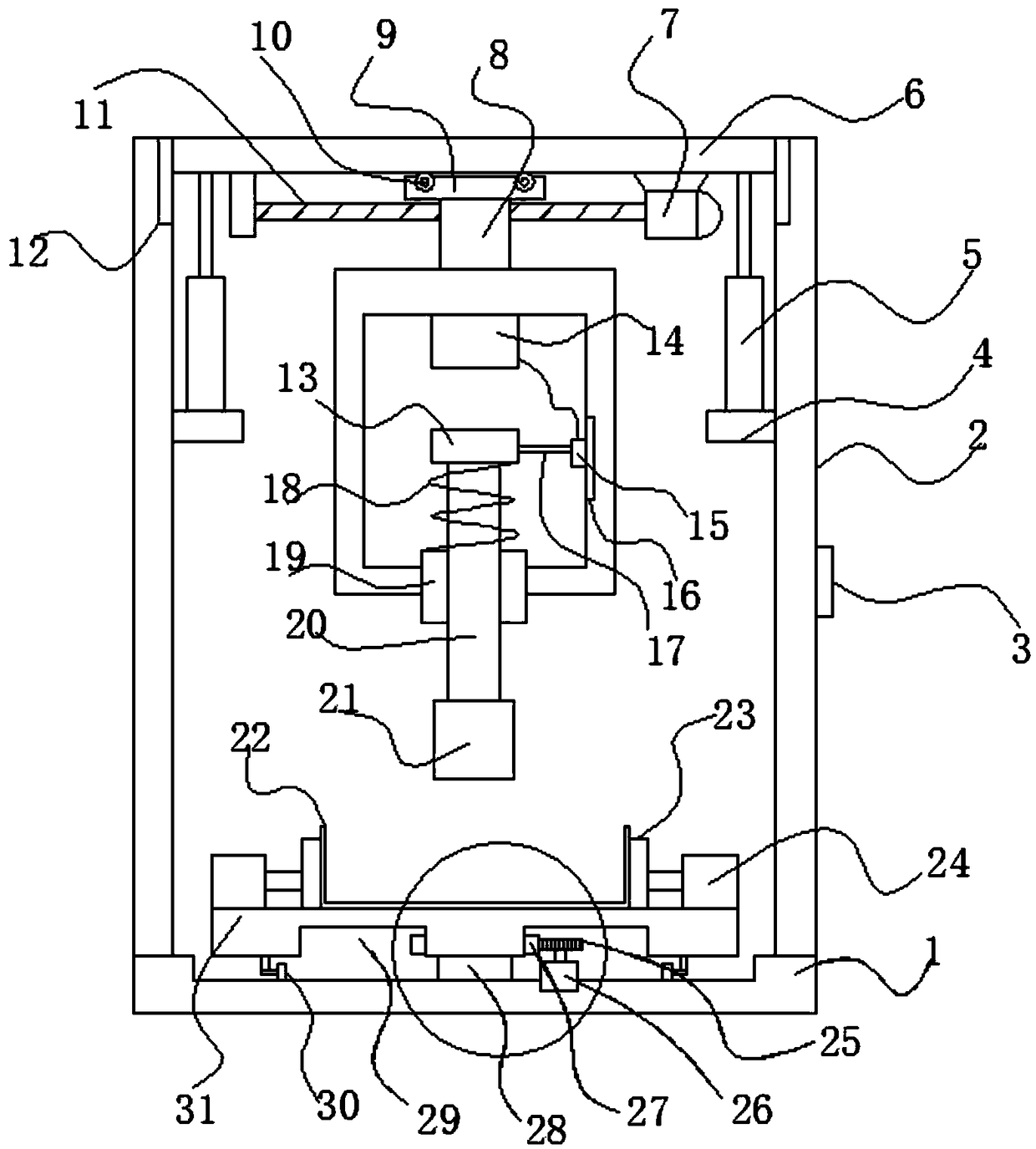

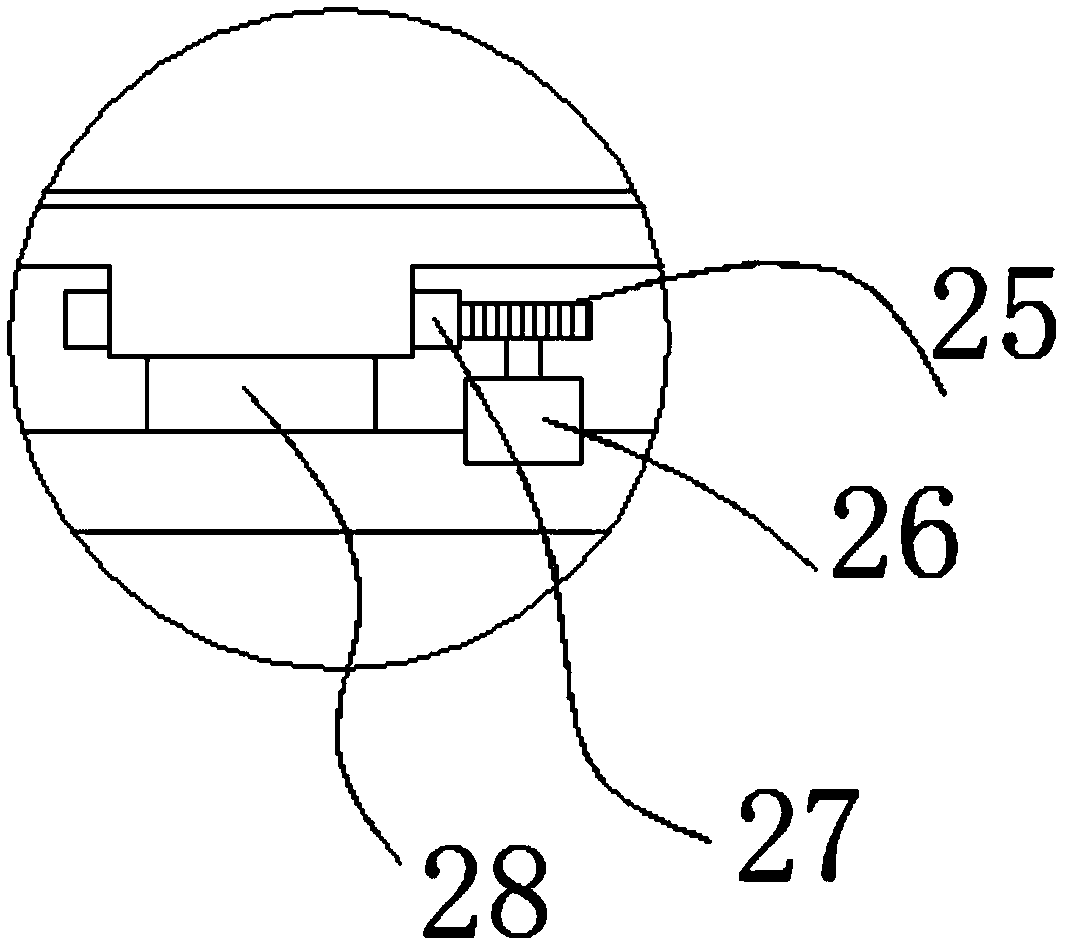

Embodiment 1

[0022] see Figure 1~3 , in an embodiment of the present invention, an electromagnetic building brick crushing device includes a base 1 and a support plate 2, the support plates 2 are symmetrically arranged on both sides of the upper end of the base 1, and a lift is provided between the upper ends of the two support plates 2. Plate 6, the lower end of the lifting plate 6 is provided with a fixed frame, the lower end of the fixed frame is provided with a guide sleeve 19, the guide sleeve 19 is slidingly fitted with a sliding rod 20, the lower end of the sliding rod 20 is provided with a crushing head 21, and the upper end of the sliding rod 20 is provided with a mounting block , the installation block and the upper end of the guide sleeve 19 are connected and fixed by the return spring 18, the inside of the fixed frame is provided with an electromagnetic drive mechanism that drives the sliding rod 20 to reciprocate up and down, the upper end of the base 1 is provided with a rota...

Embodiment 2

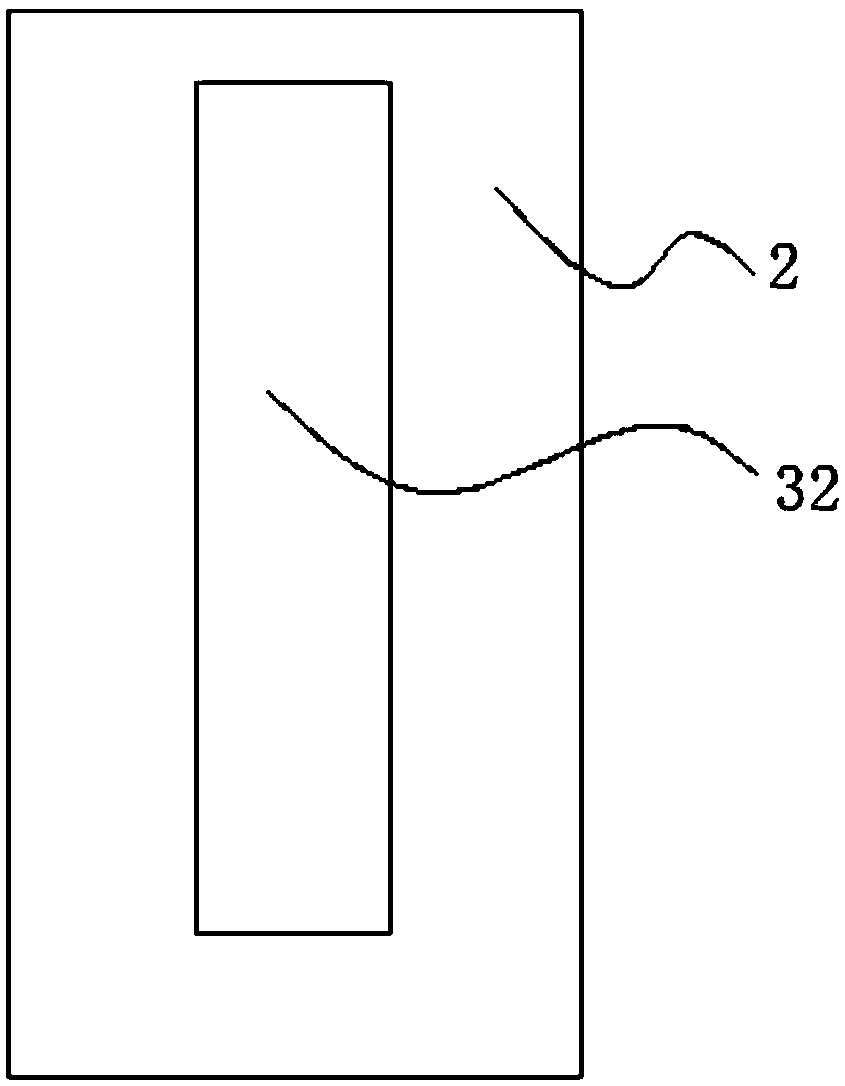

[0029] The difference from Embodiment 1 is that: the left and right sides of the lifting plate 6 are symmetrically provided with lifting sliders 12, and the support plate 2 is provided with a lifting chute 32 matched with the lifting slider 12, and the inner side of the supporting plate 2 A side plate 4 is provided, and a lift cylinder 5 is installed on the upper end of the side plate 4. The output end of the lift cylinder 5 is connected and fixed to the lift plate 6. Driven by the lift cylinder 5, the lift plate 6 slides up and down along the support plate 2, thereby realizing Adjustment of crushing height.

[0030] The adjustment mechanism, the electromagnetic drive mechanism and the lifting cylinder 5 are electrically connected to the control panel 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com