An automatic steel wire brush machine

A brush machine and automatic manufacturing technology, which is applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve the problems of life-threatening, high labor costs, and easy to be injured, and achieve the reduction of steel wire material loss, reasonable structural design, and guaranteed use. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

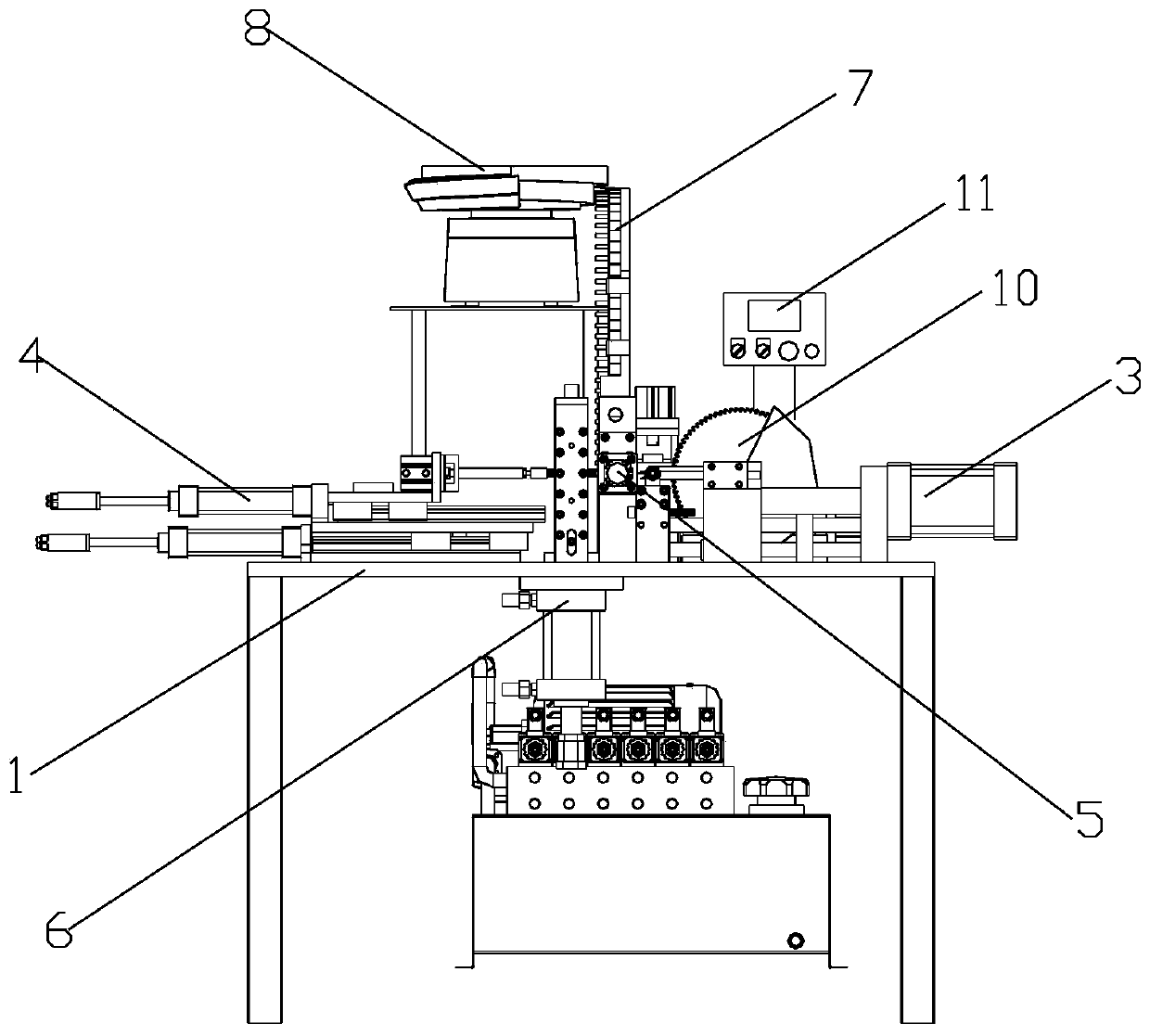

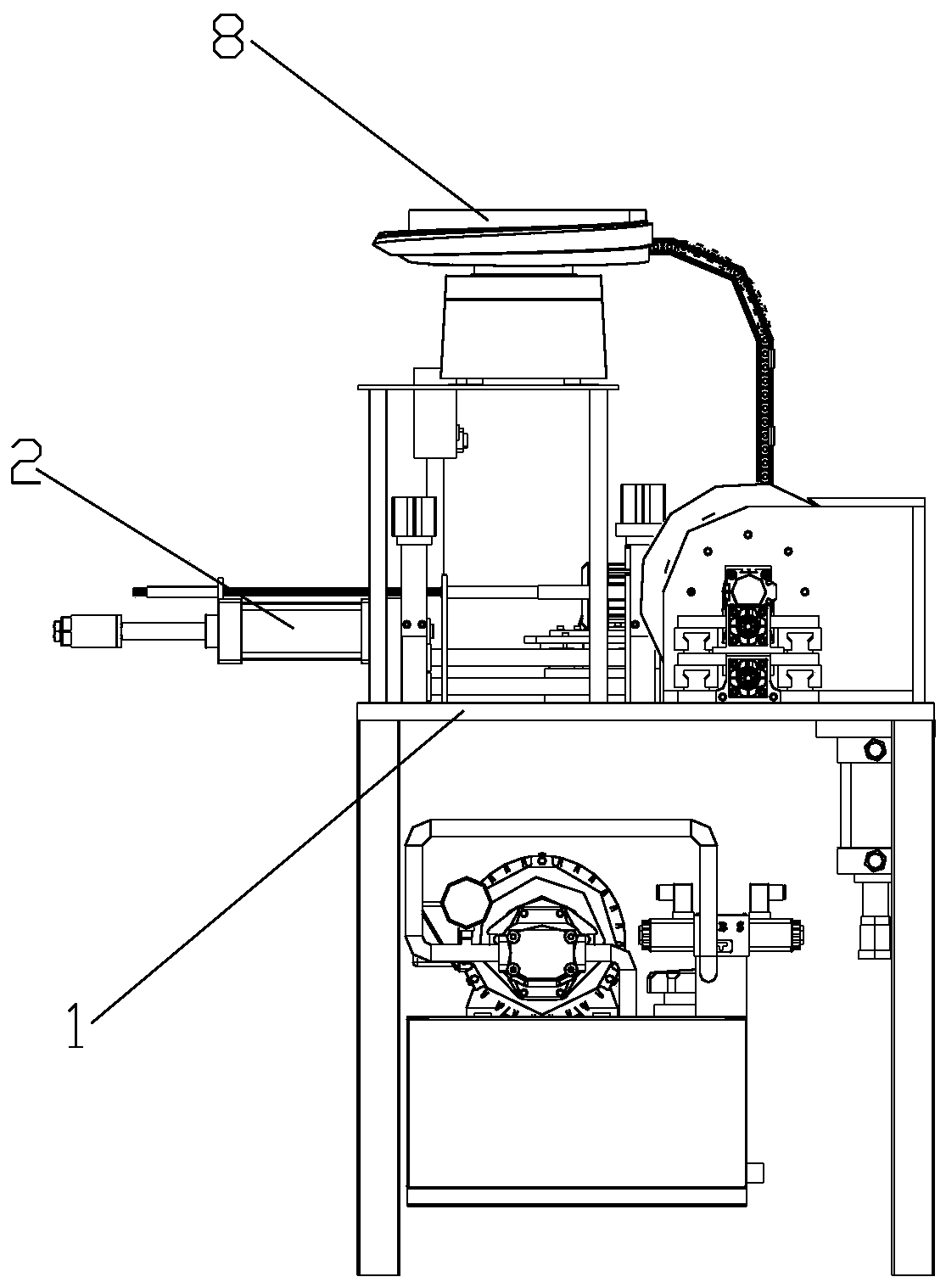

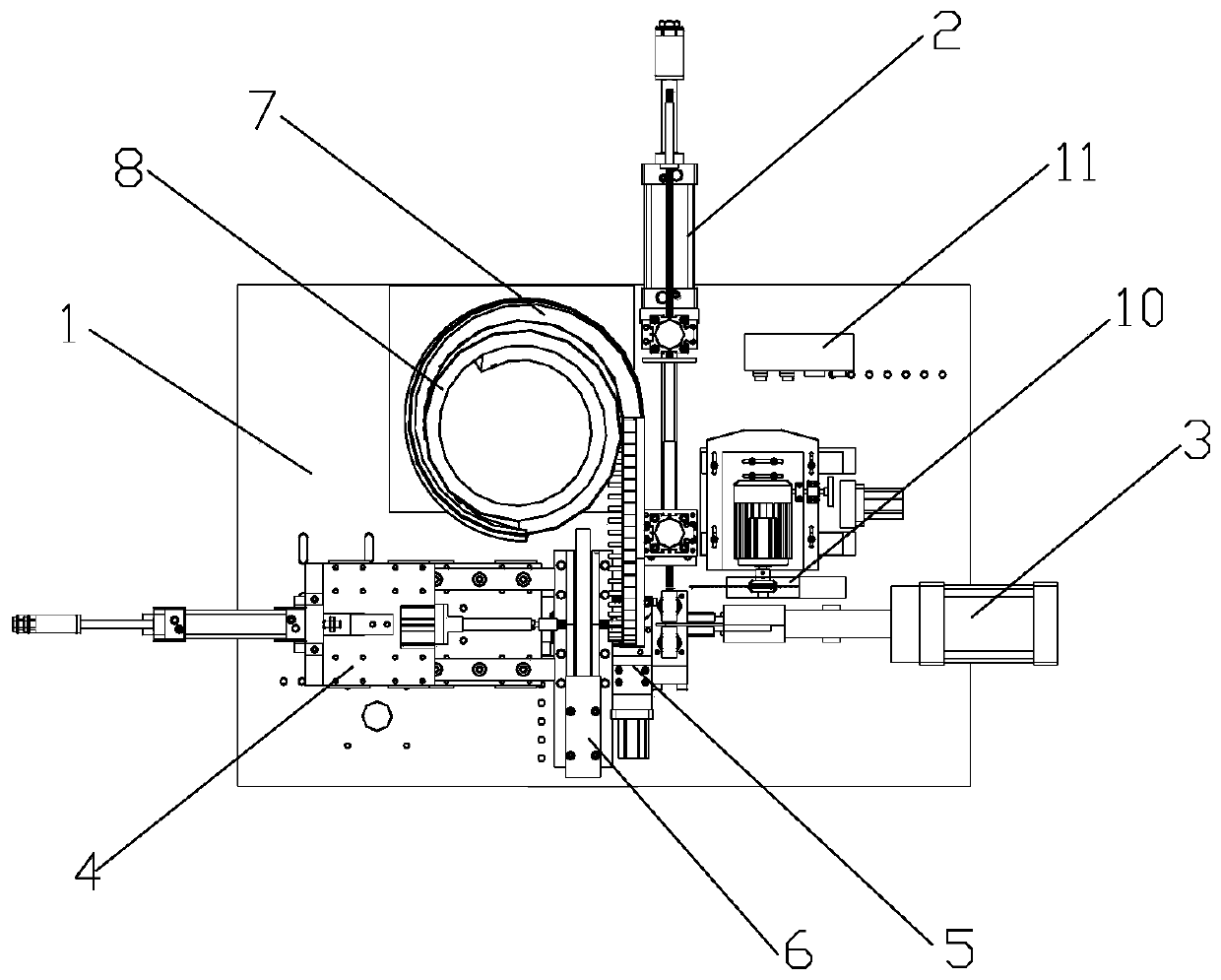

[0028] Such as Figure 1-Figure 15 As shown, the specific embodiment adopts the following technical scheme: it includes a workbench 1, a steel wire entering device 2, a pushing steel wire pressing device 3, a manipulator 4, a brush cap feeding auxiliary wire feeding mechanism 5, a locking mechanism 6, and a track 7 , vibrating plate 8, bracket 9, wire cutting mechanism 10, controller 11, steel wire entering device 2, pushing steel wire pressing device 3 and manipulator 4 are installed on the table of workbench 1, between pushing steel wire pressing device 3 and manipulator 4 A brush cap feeding auxiliary wire feeding mechanism 5 and a locking mechanism 6 are installed between them. A track 7 is installed on the brush cap feeding auxiliary wire feeding mechanism 5. One end of the rail 7 is wound on the vibrating disc 8, and the vibrating disc 8 passes through the bracket 9. Fixed on the workbench 1, the wire cutting mechanism 10 is set on the workbench 1 through the wire cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com