Capacitor feeding device and annular capacitor production equipment

A technology for capacitors and transfer devices, which is applied to capacitors, tin feeding devices, auxiliary devices, etc., and can solve problems such as low welding accuracy, instability, and interference from dust and impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] The present invention will be further described below with reference to the drawings and embodiments of the specification.

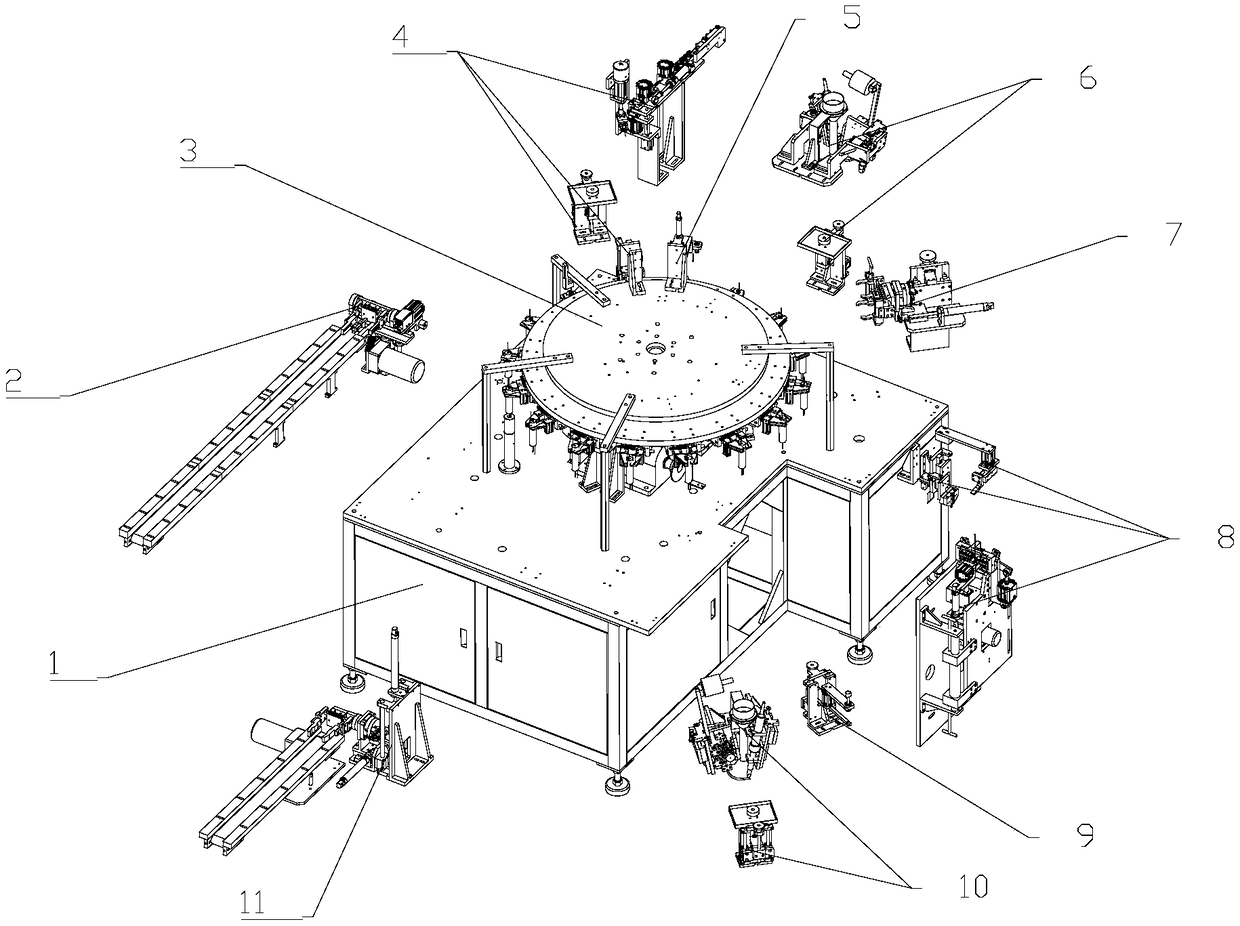

[0041] Such as figure 1 As shown, the circular capacitor production equipment includes a rack 1 and a capacitor feeding device installed on the rack 1, a turntable transfer device 3, a tinned wire spot welding device 4, a tinned wire detection device 5, and tinned Wire welding device 6, capacitor flip device 7, glue wire spot welding device 8, glue wire detection device 9, glue wire welding device 10, and finished product blanking device 11.

[0042] The turntable transfer device 3 is installed in the central part of the frame 1 to drive the workpiece to rotate; along the direction of material travel on the turntable transfer device 3, the capacitor feeding device 2, the tinning wire spot welding device 4, the tinning wire detection Device 5, tinning wire welding device 6, capacitance flipping device 7, glue wire spot welding device 8, glue wire detect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap