A thin-thick interval lamination method for microstructure mold

A manufacturing method and microstructure technology, which is applied in the field of mold making, can solve the problems of difficult positioning of the knife, unguaranteed straightness of the edge of the sheet, insufficient rigidity, etc., to avoid the requirements of knife setting and straightness, and to improve the burr phenomenon , Reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0022] The embodiment of the present invention discloses a thin-thick spacer lamination method for a microstructure mold, which includes the following steps:

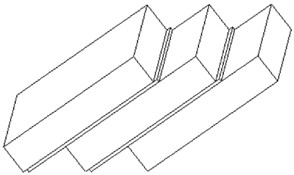

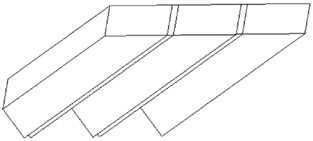

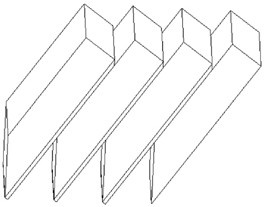

[0023] Step (1), select a thick metal sheet with a thickness of 1mm-5mm and a thin metal sheet with a thickness of 0.05mm-0.5mm; superimpose the thick metal sheet and the thin metal sheet to form a metal splicing block, and the metal sheet is located in the adjacent thick metal sheet Between the sheets, at the same time, the thin metal sheet and the thick metal sheet on the left form a metal unit, and the metal units are arranged in an oblique dislocation, and the inclination angle of the metal unit relative to the horizontal plane is 35.25 degrees; figure 1 shown;

[0024] Step (2), flatten or grind the front and rear side planes of the metal splicing block; process the upper dislocation sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com