Bottle picking placing carrying mechanism

A bottle and motor base technology is applied in the field of mechanisms for picking, placing and transporting bottles to achieve the effects of improving reliability and production efficiency, simple structure, high-speed, high-efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

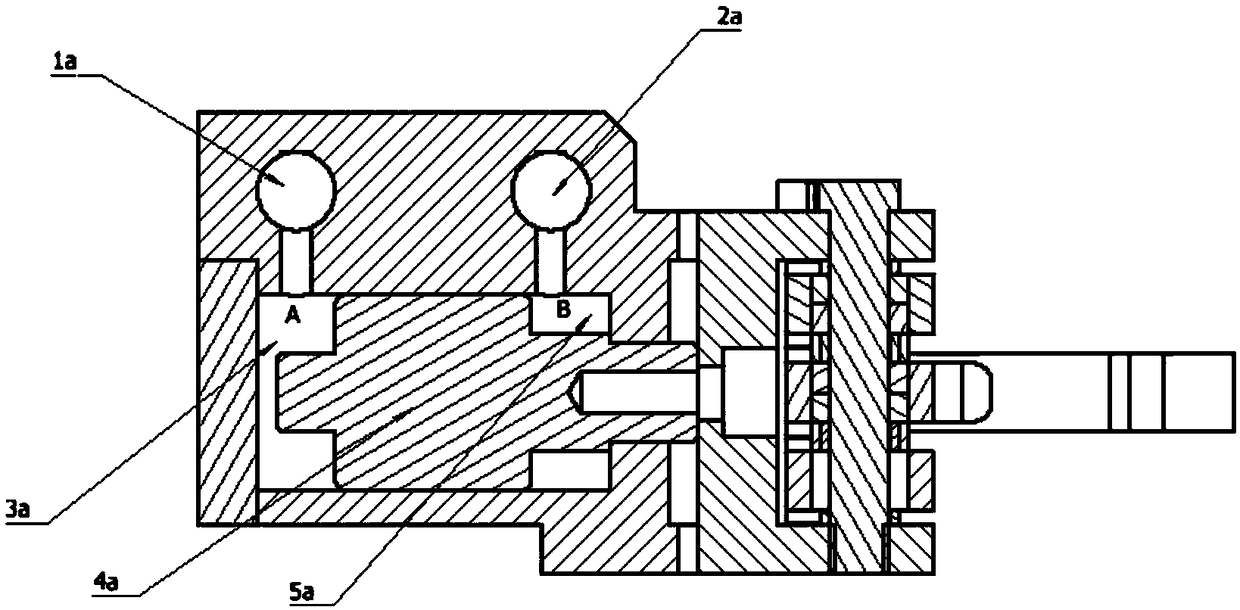

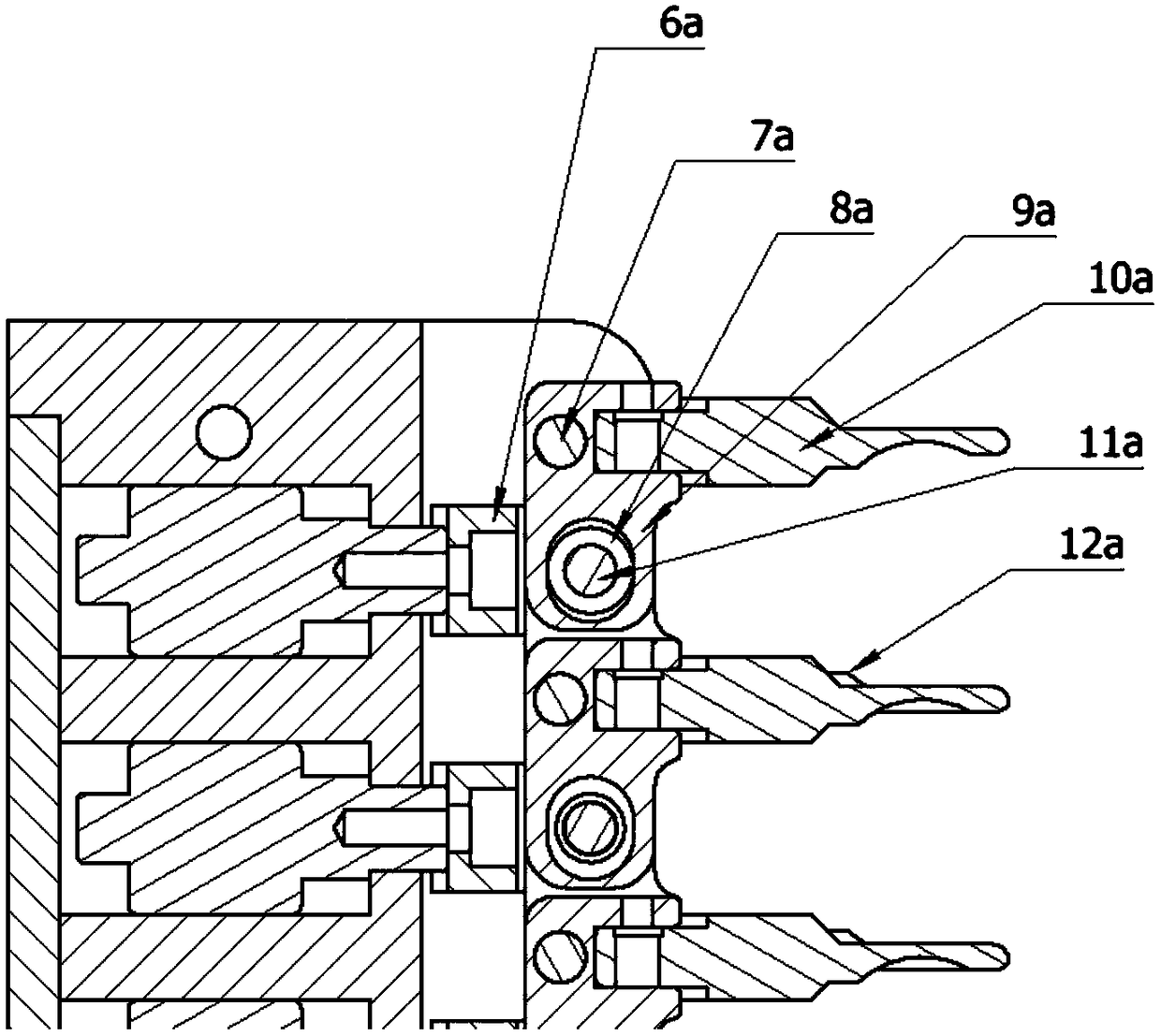

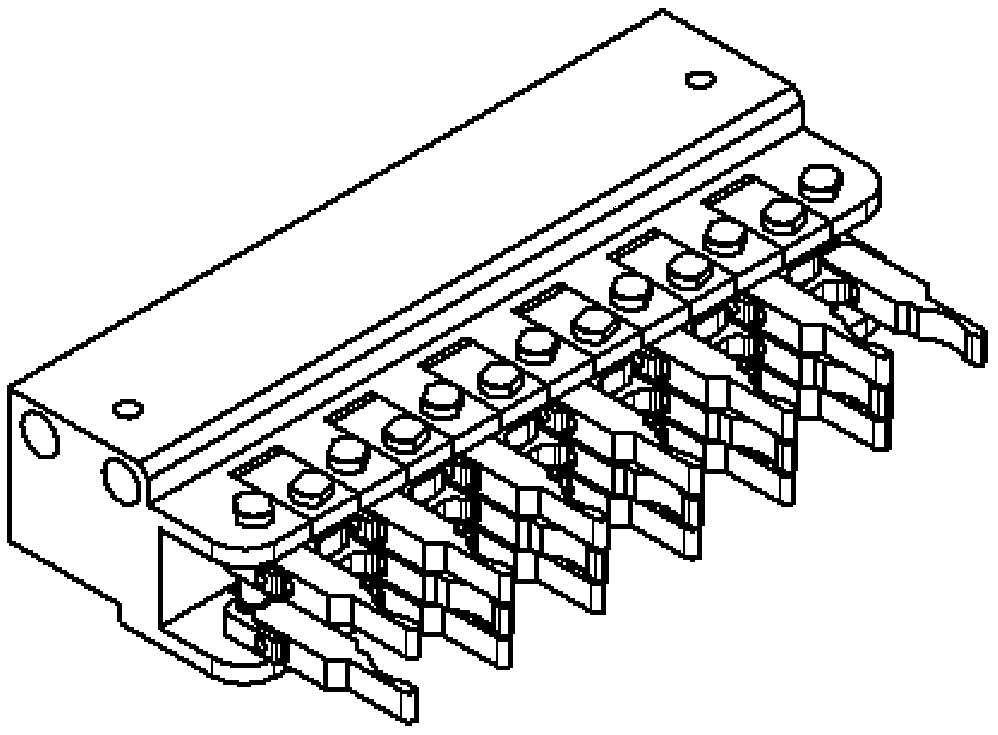

[0023] The present invention is a mechanism for picking and placing and carrying bottles, such as Figure 1-Figure 5 As shown, it includes a servo motor 7c, the rotating end of the servo motor 7c is fixedly connected with the lower end of the cam shaft 9c, the upper and lower parts of the cam shaft 9c are respectively fixed with a cam 11c and a masking disc 10c, and the cam 11c is provided with a The follower 12c that rotates in the cam 11c is fixed on the follower seat 3c, the follower seat 3c is connected to the jaw seat 1c through a bracket, and the jaw seat 1c is provided with a second command solenoid valve The first jaw 10a and the second jaw 12a that control clamping and loosening, the main conveyor chain 13c is provided directly in front of the jaw seat 1c, and a weighing platform 14c is provided between the jaw seat 1c an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com