Fixing mechanism capable of achieving sideward positioning and clamping

A fixed mechanism and lateral positioning technology, which is applied in the direction of clamping, positioning devices, metal processing machinery parts, etc., can solve the problems of product easy to touch and scratch processing, uneven locking force, unstable product positioning, etc., and achieve reduction The effect of product scrap rate, uniform strength, improvement of work efficiency and operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

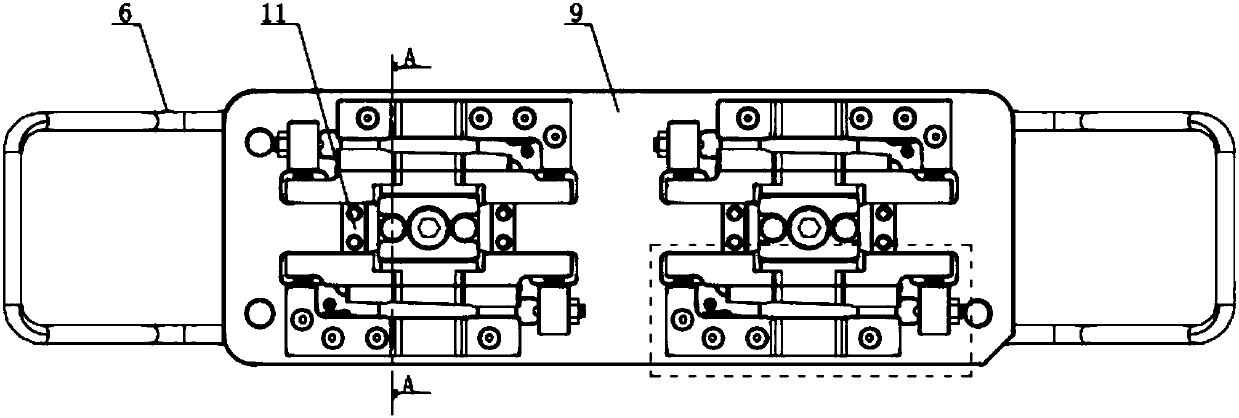

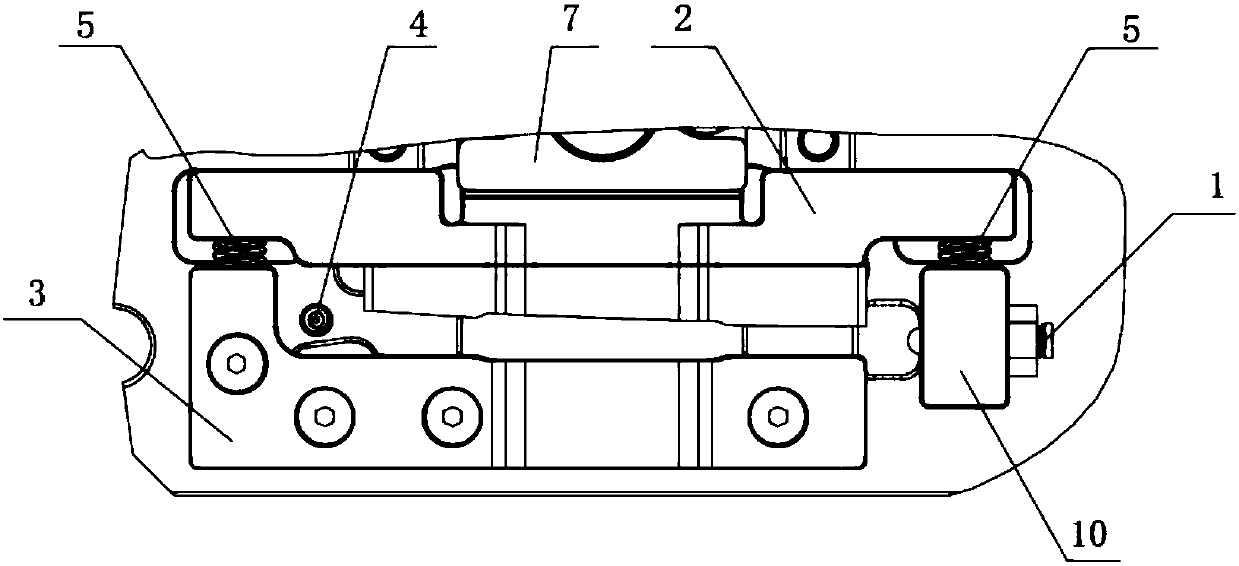

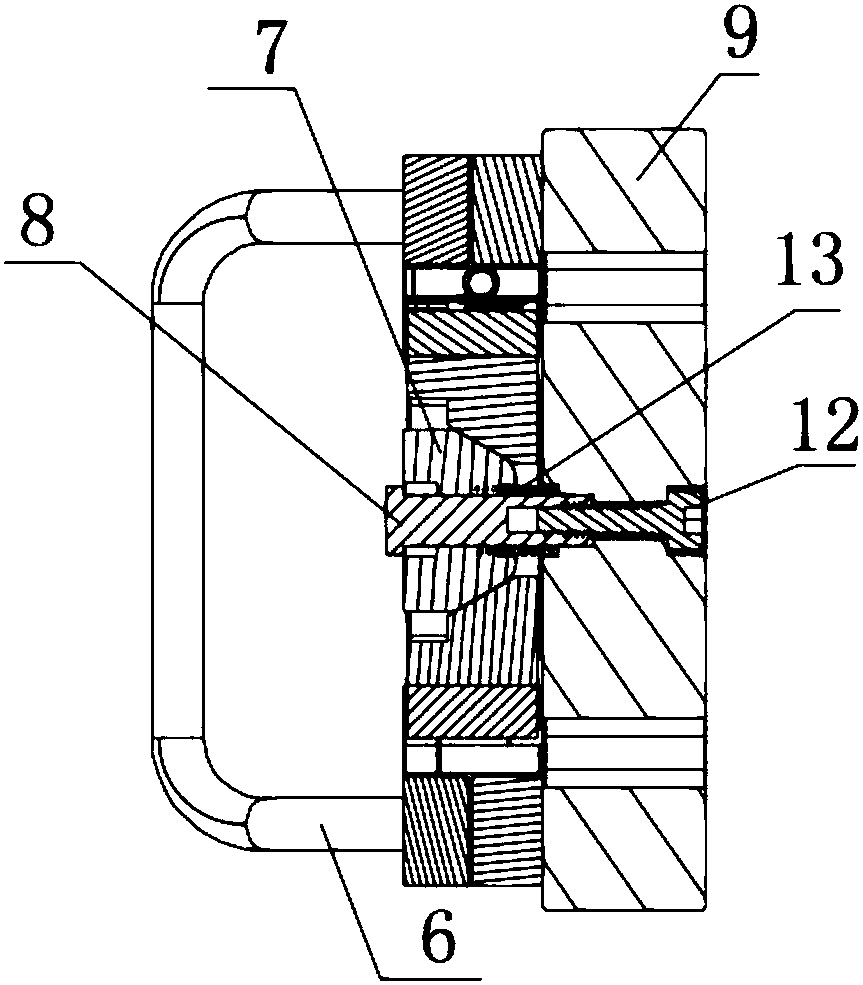

[0014] Such as Figure 1 to Figure 3 As shown, this embodiment provides a lateral positioning, clamping and fixing mechanism, which includes a clamp body 9 on which there are four locating pockets distributed in the shape of a cross; the locating pockets are provided with The first fixed stop 3 and the second fixed stop 10 on the right side of the first fixed stop 3; the second fixed stop 10 is provided with a lateral floating pin 1 from right to left; the first fixed The rear side of the stopper 3 and the second fixed stopper 10 is also provided with a lateral push block 2; between the two ends of the lateral push block 2 and the first fixed stop 3 and the second fixed stop 10 The pre-tensioning springs 5 are respectively provided; the positioning hole between the first fixed stop 3 and the lateral pushing block 2 is also provided with a pre-positioning pin 4; one of the two front and rear lateral pushing blocks 2 of the positioning hole There is also a chamfering block 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com