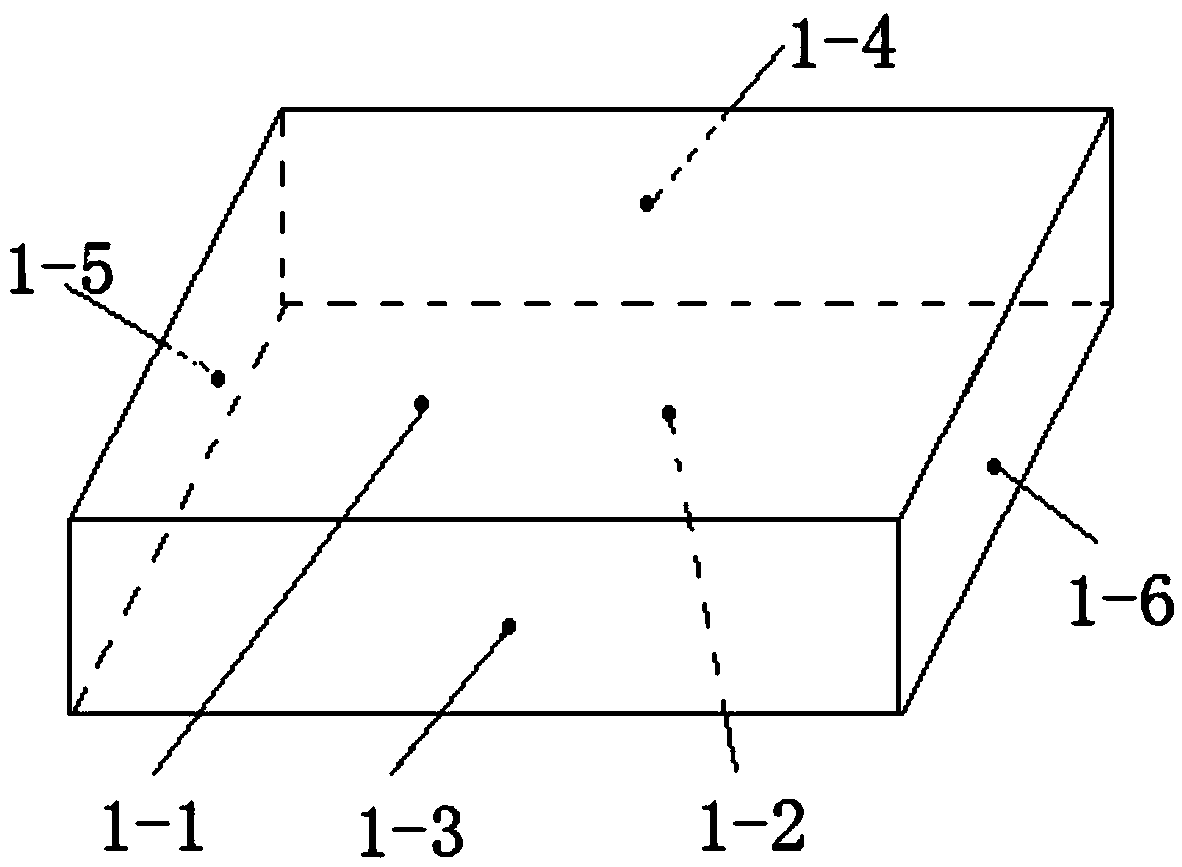

Reference reflector test block and method for measuring weld defects of thick plates

A reflector and test block technology, which is used in measuring devices, analyzing materials, analyzing solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of inability to comprehensively inspect the quality of welds, difficult to remove, and inability to adapt, so as to improve the detection work. Efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

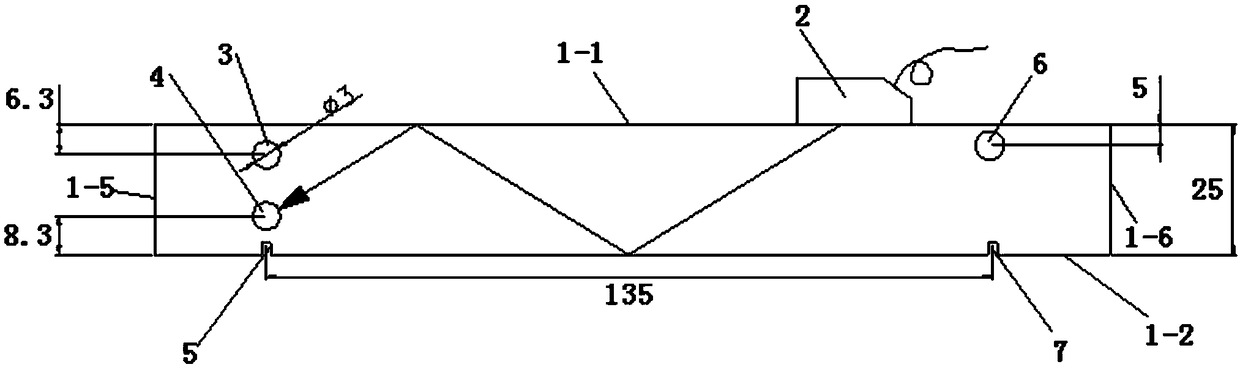

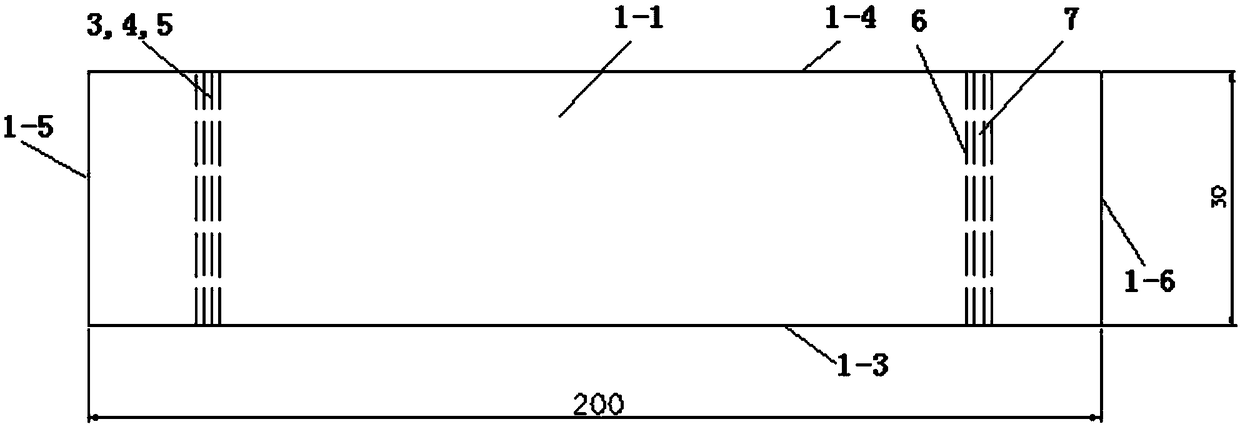

[0052] The method of using the contrast reflector test block for measuring the weld defects of thicker plates in this embodiment is as follows:

[0053] In this embodiment, the contrast reflector test block used to detect the weld seam defects of thicker plates is used to detect the strip defects in the weld seam. Use multiple reflected waves to test the depth of the hole respectively (1 / 5)t, (1 / 4)t, (1 / 3)t, (2 / 3)t, (3 / 4)t and (4 / 5) The reflected wave echo dB value of t makes the distance-amplitude curve of the hole depth. The roughness of the contrast reflector test block is the same as that of the welded steel plate, and the correction of the distance-amplitude curve may not be performed. In this embodiment, the top and bottom surfaces of the test block body 1 have the same roughness as the welded steel plate. Among them, when using multiple reflected waves to test the reflected wave echo dB values of the hole depths of (1 / 5)t, (1 / 4)t and (2 / 3)t respectively, the angle pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com