An online defect detection device for silicon solar cells

A silicon solar cell and detection device technology, applied in the field of solar cells, can solve the problems of non-uniform defect indicators of detection equipment and methods, unsuitability for large-scale industrial production, and low defect detection accuracy, so as to reduce silicon material consumption and structure Simplicity, increased automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

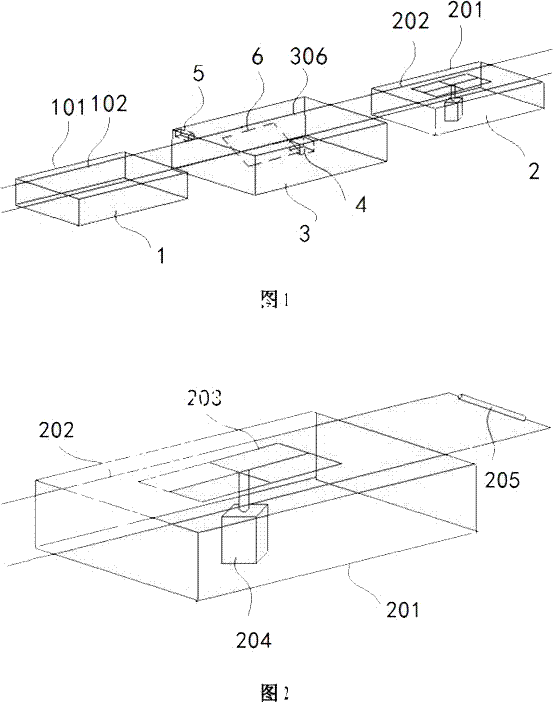

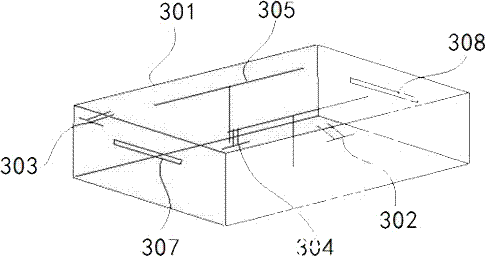

[0028] Such as figure 1 , the on-line defect inspection device for silicon solar cells of the present invention includes: a first transmission mechanism 1 , a second transmission mechanism 2 , a detection dark box 3 , a camera 4 , a DC power supply 5 and a mirror 6 .

[0029] The first conveying mechanism 1 includes a first base frame 101 and a first conveying chain 102 arranged above the first base frame. The first conveying mechanism 1 is arranged on the left side of the detection dark box 3, and the first conveying chain 102 is used to convey silicon solar cells in a straight line. The conveying chain 102 includes two rows of conveying chains, and each row of conveying chains is made of plastic Composed of chains, sprockets and guide rails, the distance between the two rows of conveyor chains is less than the width of the silicon solar cells.

[0030] Such as figure 2 As shown, the second conveying mechanism 2 includes a second base frame 201 , a second conveying chain 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com