Mask plate, mask plate defect repairing method, mask plate using method and semiconductor structure

A defect repair and mask technology, applied in the field of semiconductor structure, can solve the problem of high cost, achieve high accuracy, improve repair rate and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]As described in the context, the cost of existing mask version defects is high.

[0029]Figure 1 to 4 It is a structural diagram of a mask version of the lack of repair method.

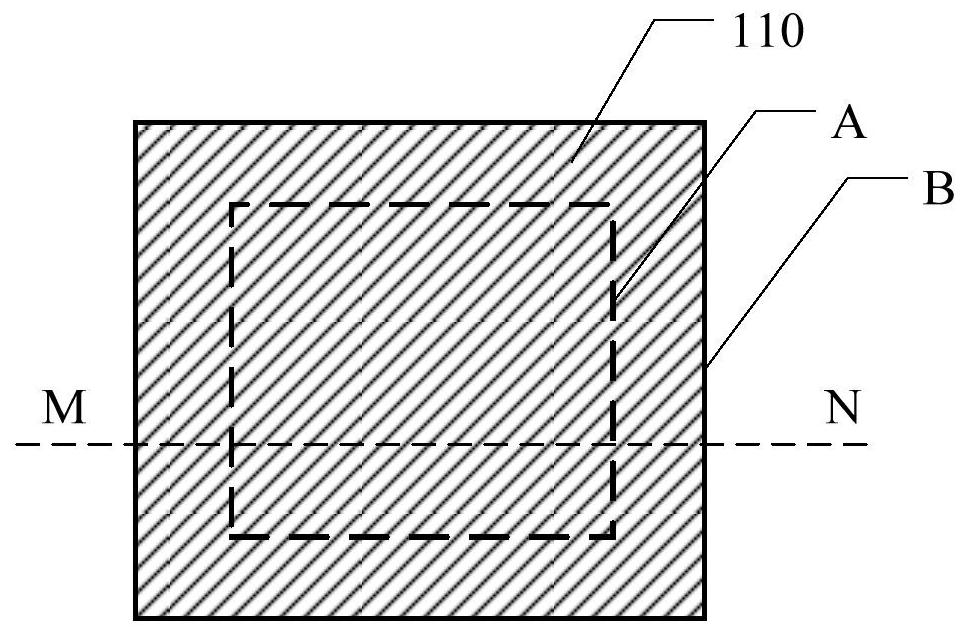

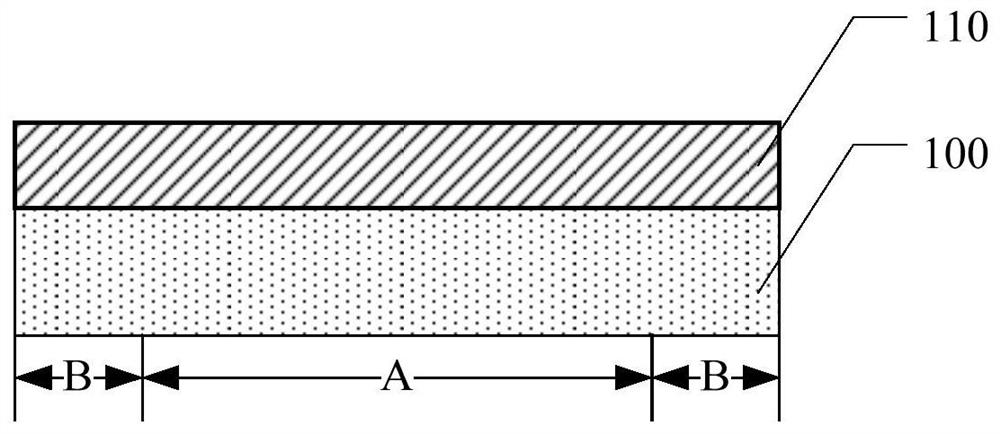

[0030]Please refer toFigure 1 to 2 ,figure 2 Yesfigure 1 A cross-sectional structure in the M-N tangent direction provides a substrate 100 that includes a region A region and a B region surrounding the A region, the substrate 100 having an initial light shielding layer 110.

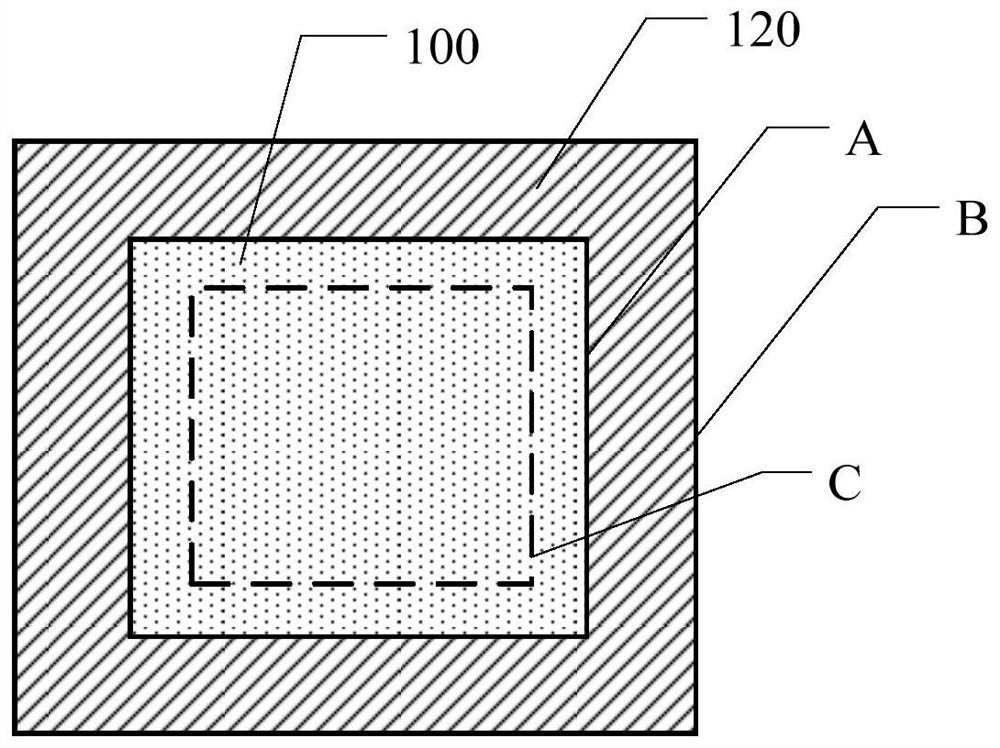

[0031]Please refer toFigure 3 to 4 ,image 3 Infigure 1 Based on the schematic,Figure 4 Infigure 2 Based on the schematic, the initial light shielding layer 110 is etched, and the light shielding layer 120 is formed on the B region, and the light shielding layer 120 has an opening 130, and the opening 130 is exposed to the surface of the A region.

[0032]In the above mask version of the lack of repair, the initial light shielding layer 110 is etched by an electron beam 140 mating gas to form a light shielding layer 120 and an opening 130 loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com